ID07 User Manual ◄ 11

WRENCH TORQUE INFORMATION

FACTORS THAT AFFECT TORQUE

An impact wrench is a rotary hammer that impacts the head of a bolt or nut. It does not apply a slow steady torque

as a standard torque wrench. Therefore, several factors aect the result of torque when using impact wrenches:

1. LONG BOLTS. Long bolts having high-friction threads with lubrication under the bolt head or associated nut

can twist when impacted, then untwist before the next impact. This will especially happen if there is low friction

between the bolt head or nut and the mating surface.

2. HEAVY, LOOSE OR MULTIPLE ADAPTERS. Heavy, loose or multiple adapters between the wrench and

socket can dissipate the intensity of the impact to the bolt head or nut.

3. AMOUNT OF IMPACT. Maximum torque results can be obtained by allowing continuous impacting of the

socket against the bolt head or nut for at least 10 seconds.

4. HYDRAULIC FLOW RATE. If the ow rate to the tool is too low, the hammer (or impact) speed is reduced. If

the ow is correct, a change in the relief pressure does not aect the impact force. Poorly designed hydraulic

circuits can result in lower ow rates and reduced impact speeds when pressure is required during impacting.

BOLT GRADE AND THREAD RECOMMENDATIONS

Allowable bolt torque is limited by both bolt thread diameter and grade of steel in the bolt. The ID07 Impact Wrench

is recommended for use on the following bolt grade and thread sizes:

SAE Grade 2 7/16 to 7/8 inch / 11 to 22 mm

SAE Grade 5 3/8 to 5/8 inch / 9 to 16 mm

SAE Grade 8 3/8 to 9/16 inch / 9 to 4 mm

PREPARATION PROCEDURES

CHECK POWER SOURCE

1. Using a calibrated ow meter and pressure gauge, check that the hydraulic power source develops a ow of

4–12 GPM/15–45 LPM at 2000 psi/140 bar. Proper ow and pressure maintain proper tool speed.

2. Make certain that the hydraulic power source is equipped with a relief valve set to open at 2100 psi/145 bar

minimum.

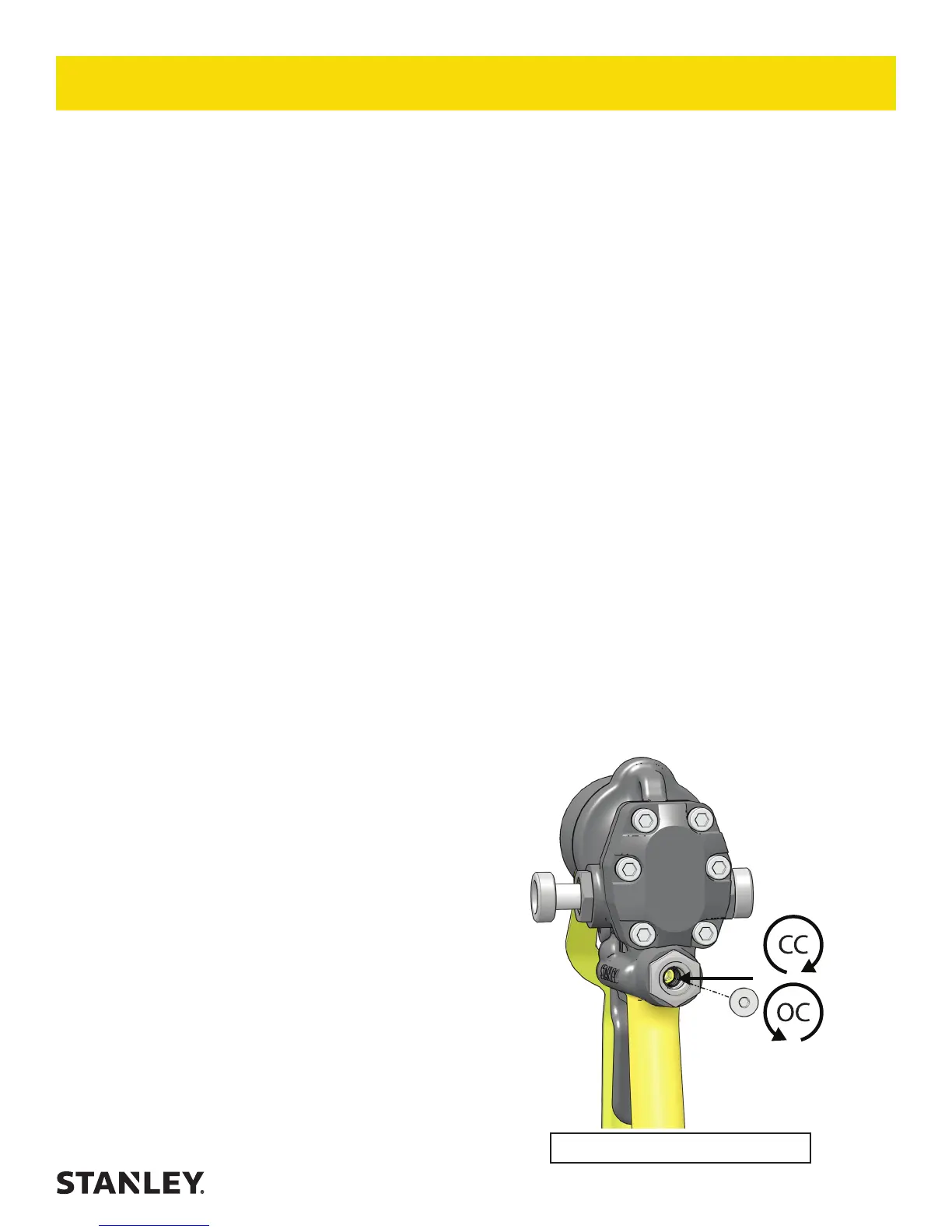

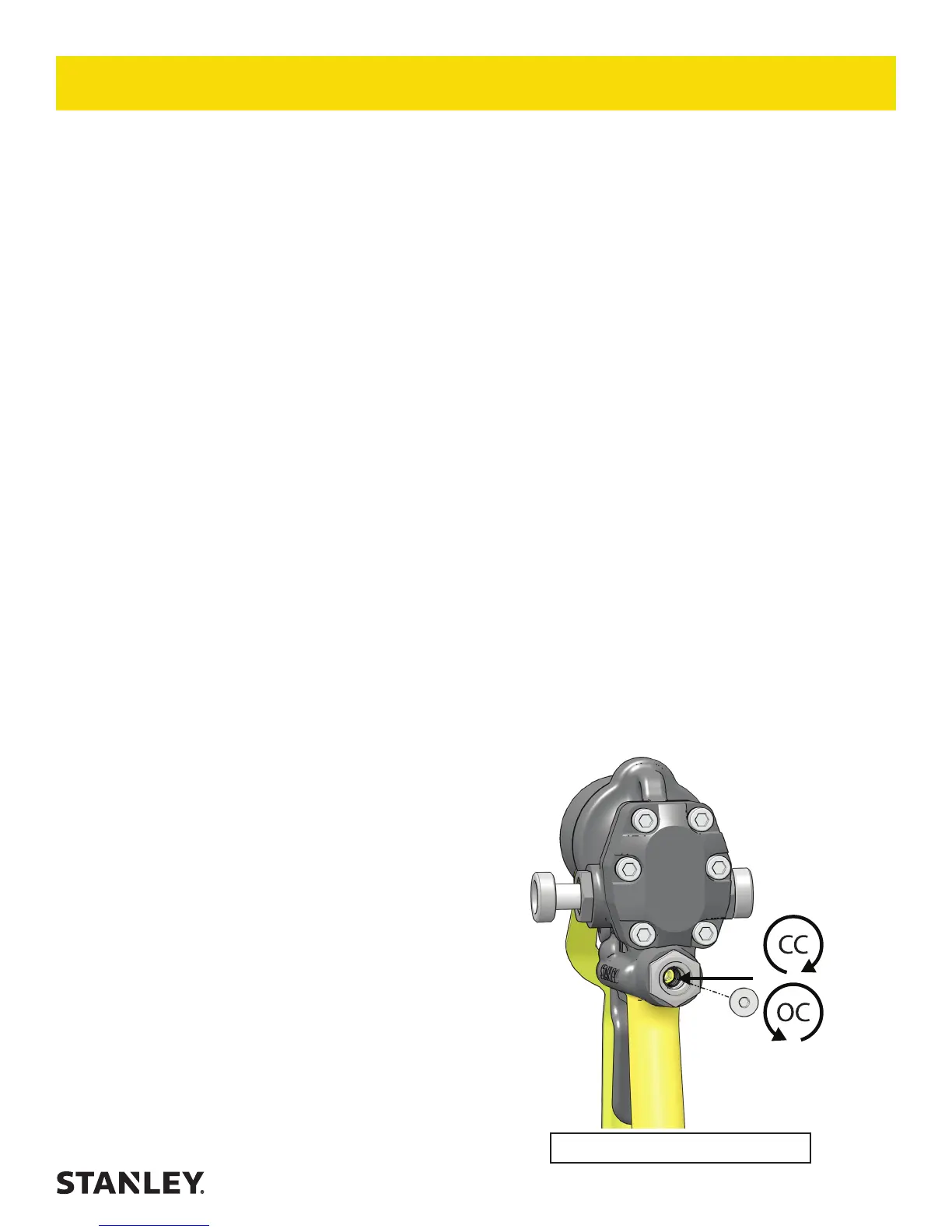

OPEN-CENTER (OC) OR CLOSED-CENTER

(CC) OPERATION - FIG. 2

The ID07 can be congured to run on OC or CC circuits.

1. Determine the system type.

2. Remove the hex plug (44) from the spring cap.

FOR OPEN-CENTER OPERATION:

Using a 3/16 in. hex, reach through the hole in the spring

cap and turn the selector screw counter-clockwise until

meeting resistance (from the retaining ring). Turn the

selector clockwise and then counter-clockwise to be sure the

selector is being stopped by the retaining ring. Do not force

the selector screw. Open-center operation is now selected.

FOR CLOSED-CENTER OPERATION:

Using a 3/16 in. hex, reach through the hole in the spring

cap and turn the selector screw fully clockwise. When the

selector screw bottoms. Closed-center operation is now

selected.

OPERATION

Figure 2 - OC/CC Conguration

Loading...

Loading...