PLUMBING

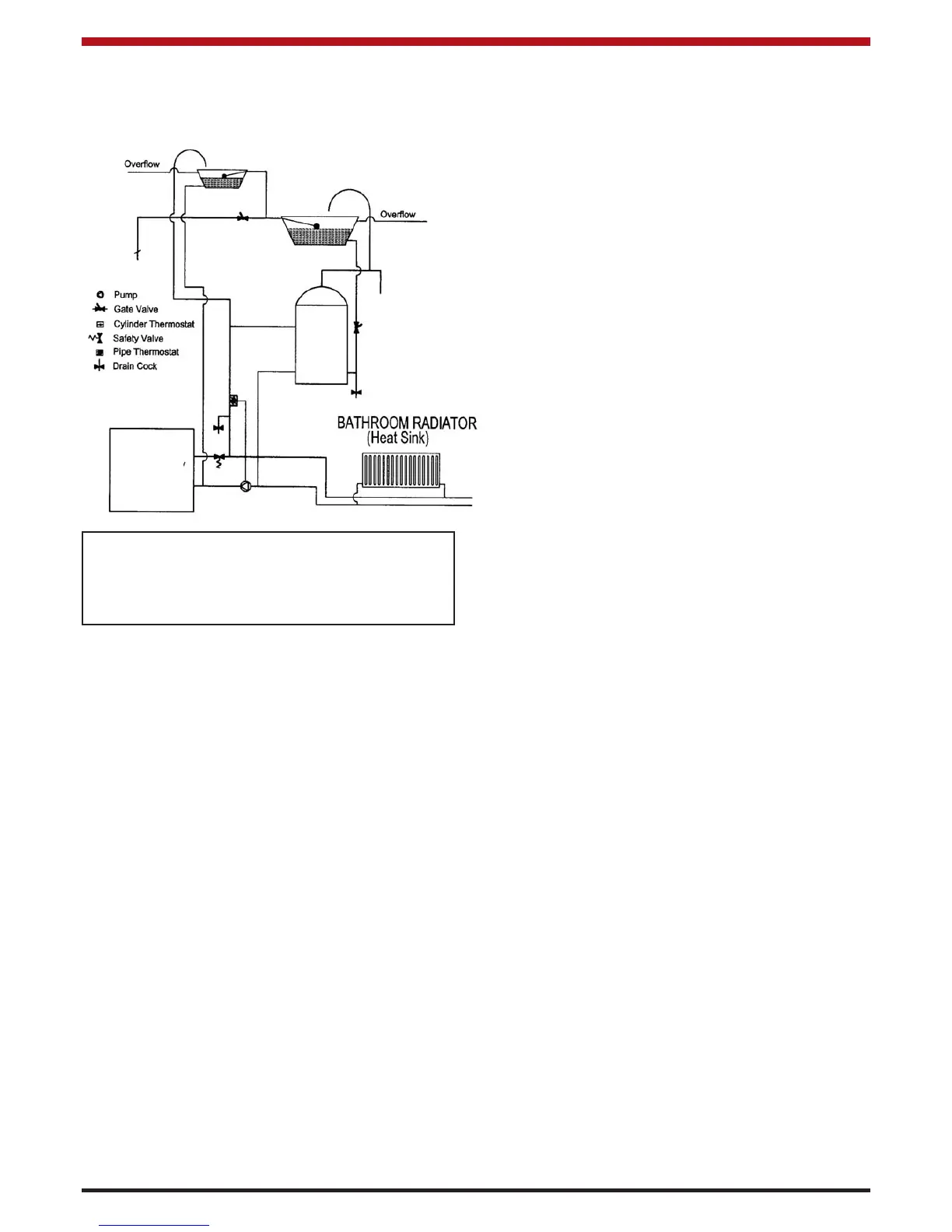

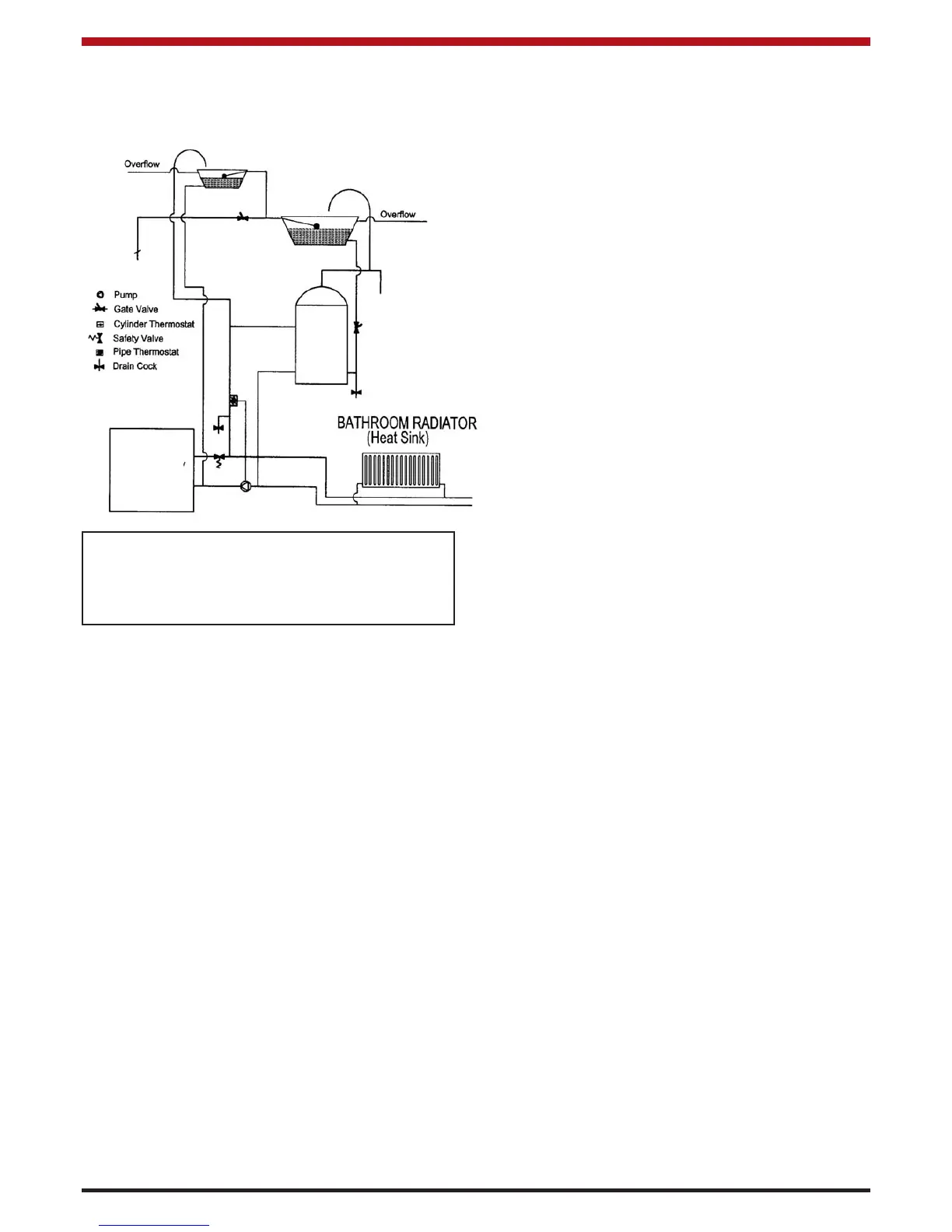

Diagrams illustrate the basic principles of water sys-

tems and are not to be regarded as working draw-

ings.

NOTE: We strongly advise the use of pipe lagging

and also the use of a frost thermostat if the installa-

tion is likely to be exposed to situations where the

temperatures will drop to a level consistent with

frost.

Central Heating and Indirect Domestic Hot

Water.

Recommended indirect cylinder 135 litres, depend-

ing on domestic requirements with a 28mm flow and

return pipes not exceeding 7.8m each in length.

Cylinder and pipework should be lagged to minimise

heat losses.

HEATING SYSTEM

The system must include a gravity circuit with

expansion pipe, open to the atmosphere. The cen-

tral heating must be pump-driven as with other types

of boilers. The primary air valve controls the heating

rate of the boiler, Closed = minimum, Open = maxi-

mum output. (See operating instructions).

BOILER OUTPUT (Central Heating)

High output cannot be maintained unless fuel is

being burned at a rate of 2.7 kg. per hour of coal.

When burning wood or peat, reduced outputs

will apply because of the lower calorific value of

the fuels.

GRAVITY CIRCUIT

The gravity circuit consists of a domestic hot water

tank of 135 litres Indirect Cylinder for central Heating

units and Direct Cylinder for Domestic Hot Water

Unit fixed in an upright position, recommended for

hot water storage and it should be connected to the

boiler by 28mm diameter flow and return piping. The

pipes should not exceed 7.8m each in length and

anything in excess of 4.6m must be fully lagged.

The shorter the run of pipe work the more effective

the water heating efficiency and to this end, the

cylinder should be fully lagged. In the interest of

safety do not have any valves on this circuit.

HEATING

Care should be taken to ensure that the heating

installation is correctly installed and that it complies

with all relevant codes of practice. If this appliance

is being connected to an existing system, it is

strongly recommended to check the following.

(a) That the pipework is adequately insulated

(where applicable).

(b) Check all controls e.g. pump, pipe thermo-

stat etc, are operating satisfactorily and

are compatible with the requirements of the

cooker.

(c) Cleanse the system and add suitable

inhibitor.

Only competent personnel should be employed to

carry out your heating installation.

PIPE FITTINGS

Materials used for installation work should be fire

resistant, sound and should conform to the current

editions of the following or their equivalent:

1. Ferrous Materials

B.S. 1387: Steel Tubes

B.S. 4127: Stainless Steel Tubes

B.S. 1740: Steel Pipe Fittings

B. S. 6956: Jointing Materials

2. Non-Ferrous Materials

EN 29453: Soft Solder Alloys

B.S. 864: Compression Tube Fittings

B.S. 2871 & EN 1057: Copper & Copper

Alloys.

WATER CIRCUIT TEMPERATURE

The return water temperature must be maintained at

not less than 50º C so as to avoid condensation on

the boiler and return piping. Fitting a pipe thermo-

stat to the return from the gravity circuit and wiring it

into the pump control will ensure than no cold water

will be returned from the central heating circuit

before the water from the gravity circuit has warmed

up the common return pipe and boiler. If this is not

sufficient to keep the boiler temperatures above the

Stanley

Solid Fuel

Range

Fig. 11

8

Loading...

Loading...