8

© 2019. All rights reserved.

This pump requires very little maintenance and

should provide a long service life. Problems are

rare; when the pump ow drops off, the most likely

cause is something solid going down the drain and

jamming the impeller.

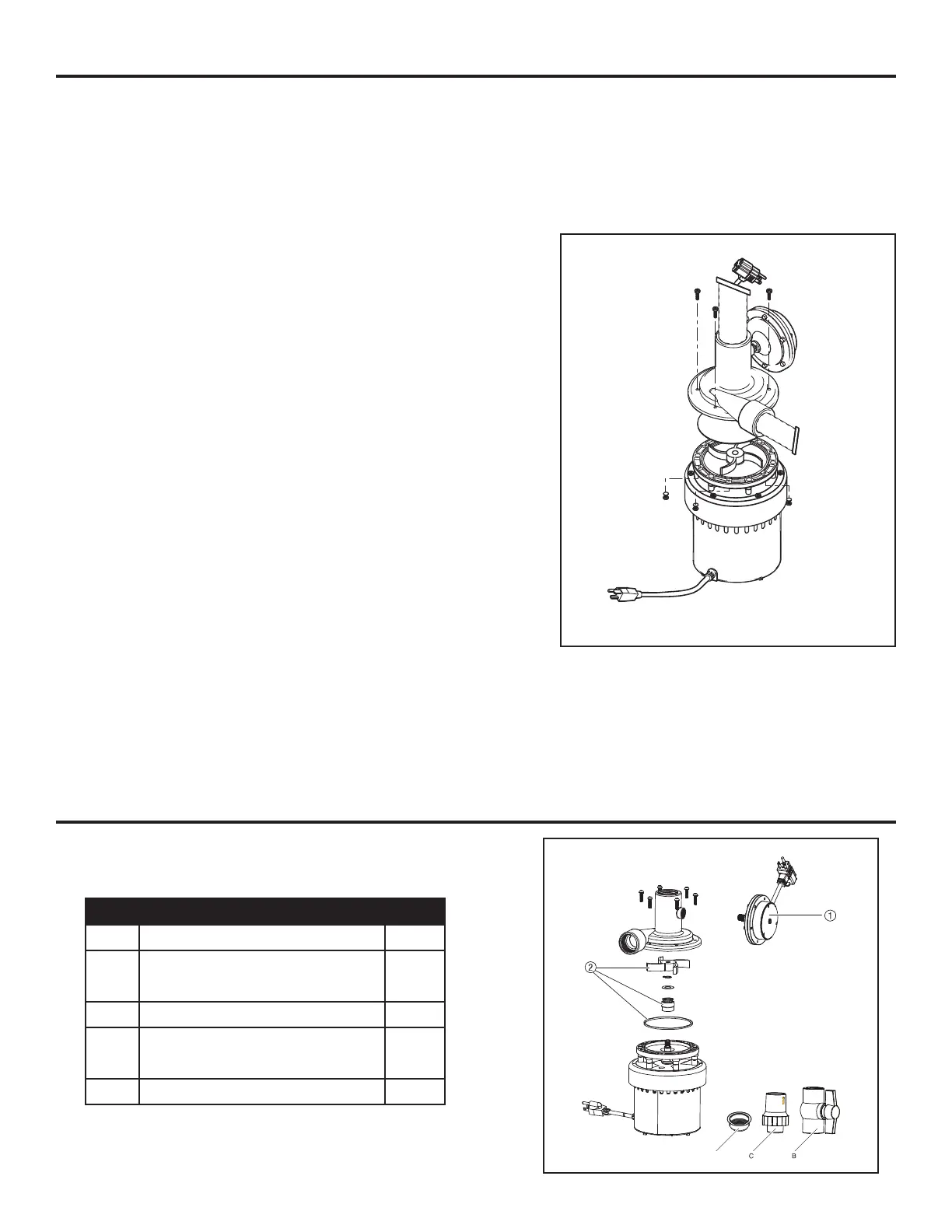

TO CLEAR A JAMMED IMPELLER:

• Unplug the pump

• Close the discharge shutoff valve

• Bail out the sink as much as possible

• Disconnect the union, unscrew the pump from

the sink tail piece, lower the pump to the oor,

and slide it out from under the sink

• Remove the six housing screws

• Clean out the pump. Make sure that the pump

discharge is clear. If necessary, replace the

impeller.

• Install the new gasket (included with impeller).

Reassemble the pump.

• Raise the pump back into position, thread it

back onto the sink tail piece, and reconnect the

union.

• Plug in the pump. Run water in the sink until the

pump has run at least one complete cycle to

make sure the pump is operating correctly and

there are no leaks.

CARE AND MAINTENANCE

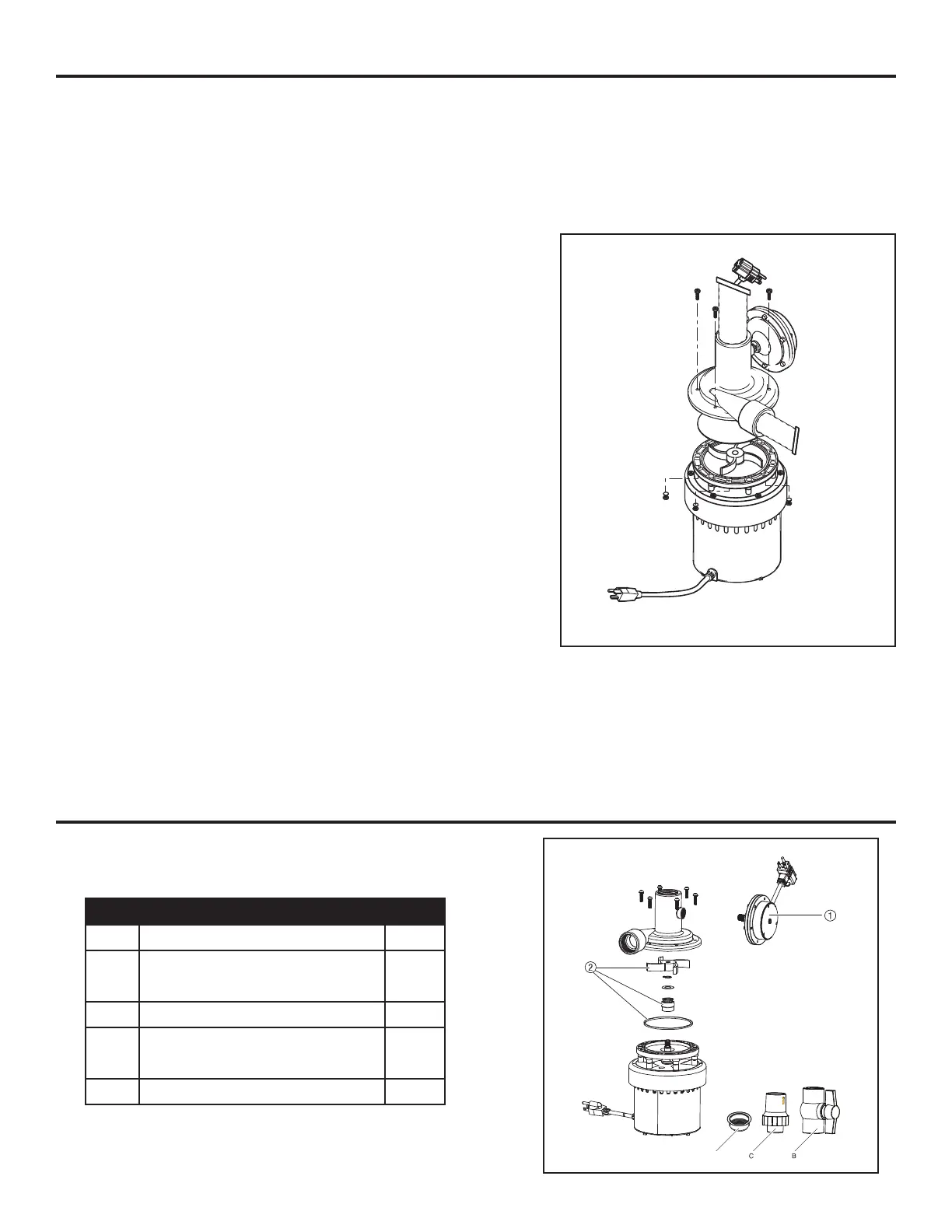

No. Description Qty.

1 Diaphragm Switch 1

2 Impeller, Gasket,

Mechanical Seal

1

D* Sink Drain Screen 1

C* 1-1/4” NPT x 1-1/4” Slip

Check Valve

1

B* 1-1/4” NPT Ball Valve 1

PARTS LIST

*Available Locally.

Loading...

Loading...