Issue 6 5 15/06/2015

6 KEY START OPERATING INSTRUCTIONS

Before attempting to start the generator ensure the engine has the appropriate amount of

lubricating oil and the fuel tank has at least 10 litres of diesel.

Turn the key to the first position, the oil and battery lamps should be illuminated.

Turn the key to crank position until engine fires, oil and battery lamps should now have

been extinguished.

Return key to run position and the generator should now be running.

To stop, turn the key to stop position.

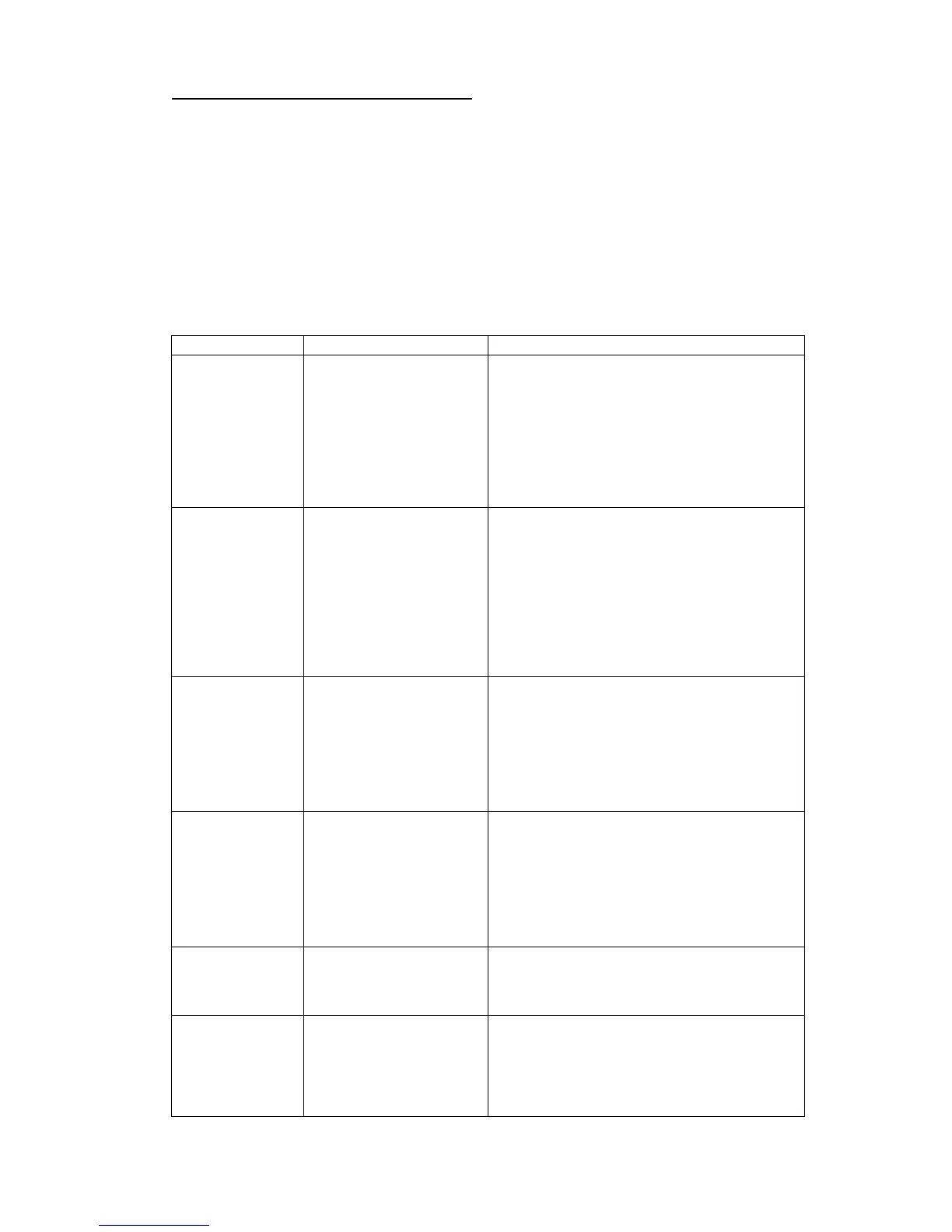

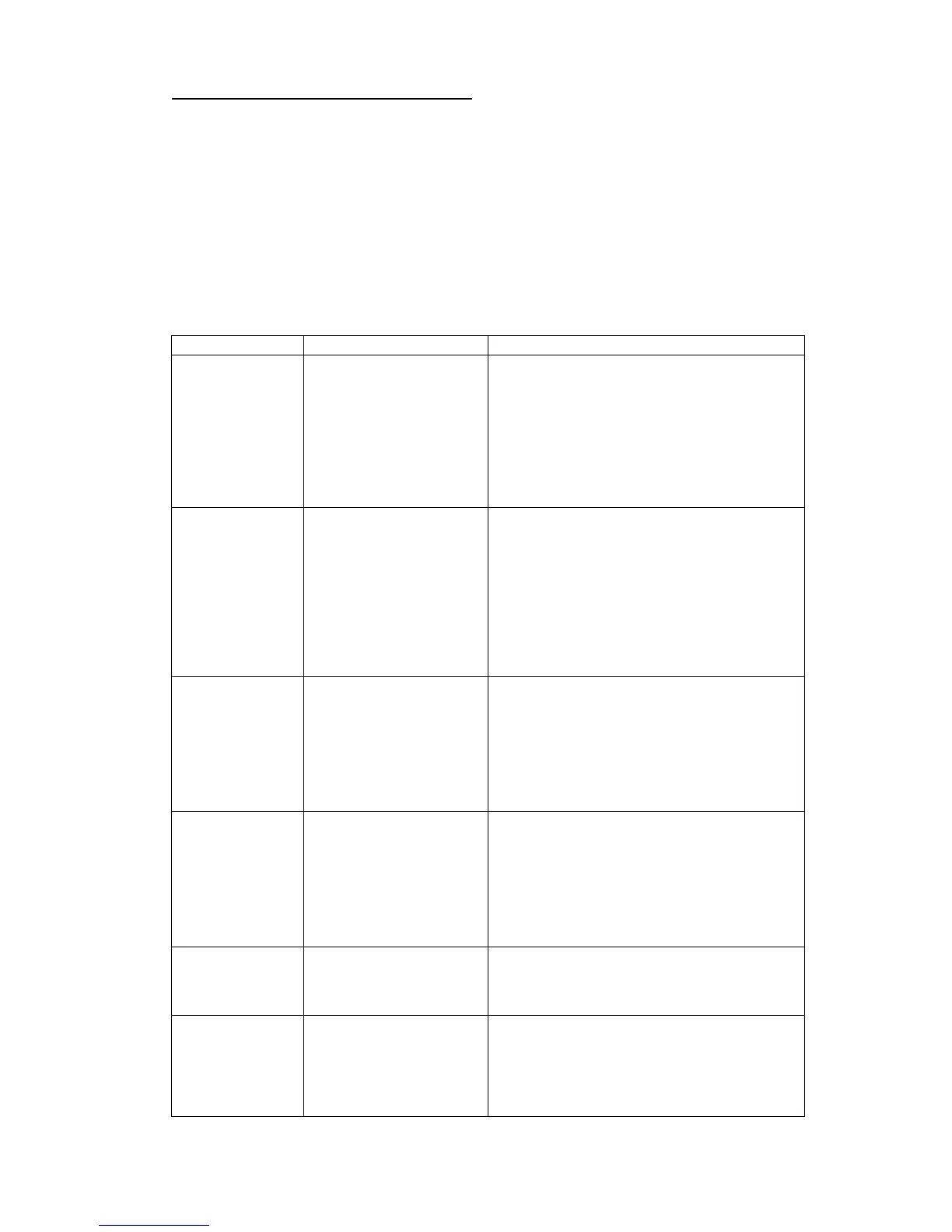

6.1 Fault finding key start

Before diagnosing a possible fault ensure all the bulbs in the fault lamps are working.

The easiest way to check is to swap the lamp heads containing the bulb into a holder

you know works eg. the battery or oil lamp. A blown bulb will not show you a possible

fault!

Starter motor not

engaging & not

starting

Battery

Reset button

Faulty wiring

Faulty starter motor

Check battery voltage, should be about 12.5V.

Check electrolyte level in battery.

Check DC reset button on control panel.

Check for loose wires on starter motor.

Check continuity from key switch to reset

button.

Check continuity from key switch to starter

motor.

Check / Change starter motor.

Starter motor

engaging & not

starting

Faulty lamps/lamp holder

Run-Stop lever in wrong

position

Fuel lamp illuminated

Full of fuel still won't run

Temperature lamp lit

Fuel Solenoid

Check bulbs and lamp holders.

Move to Run position.

See fuel lamp fault.

Check machine has not run out of fuel and

introduced air into system (bleed).

See temperature lamp fault.

Check 12v supply to solenoid.

Check solenoid is operating.

Check connections on key switch.

Battery charge

lamp illuminated

when running

Fuse blown

Wiring

Regulator

Fuse holder situated next to regulator

Check regulator and harness connections.

Check continuity (earth connection) from

regulator to body of engine.

Check AC voltage on green/white wires from

engine voltage should be 38V.

Check key switch connections.

Replace regulator.

Oil lamp stays

illuminated

during start

procedure

Low oil

Oil pressure switch

Oil pressure relay

Check oil level is at max on dip stick.

Check for signs of oil leak.

Check oil pressure switch normally closed

when engine is at rest and open when engine

running.

Replace Oil pressure switch.

Check relay for loose wires.

Check operation of relay.

Temperature

lamp stays

illuminated during

start procedure

Temperature switch

Temperature switch relay

Check operation of temperature switch

normally closed opens with fault.

Check relay for loose wires.

Check operation of relay.

Fuel lamp stays

illuminated during

start procedure

Low fuel

Faulty level switch

Fuel level relay

Check fuel level is at 1/3 a tank minimum.

Check level switch operation normally closed

with low fuel, opens when fuel level ok.

Check connections on level switch.

Check relay for loose wires.

Check operation of relay.

Loading...

Loading...