www.stiebel-eltron.com LWZ304-404 SOL | 15

INSTALLATION

Installation

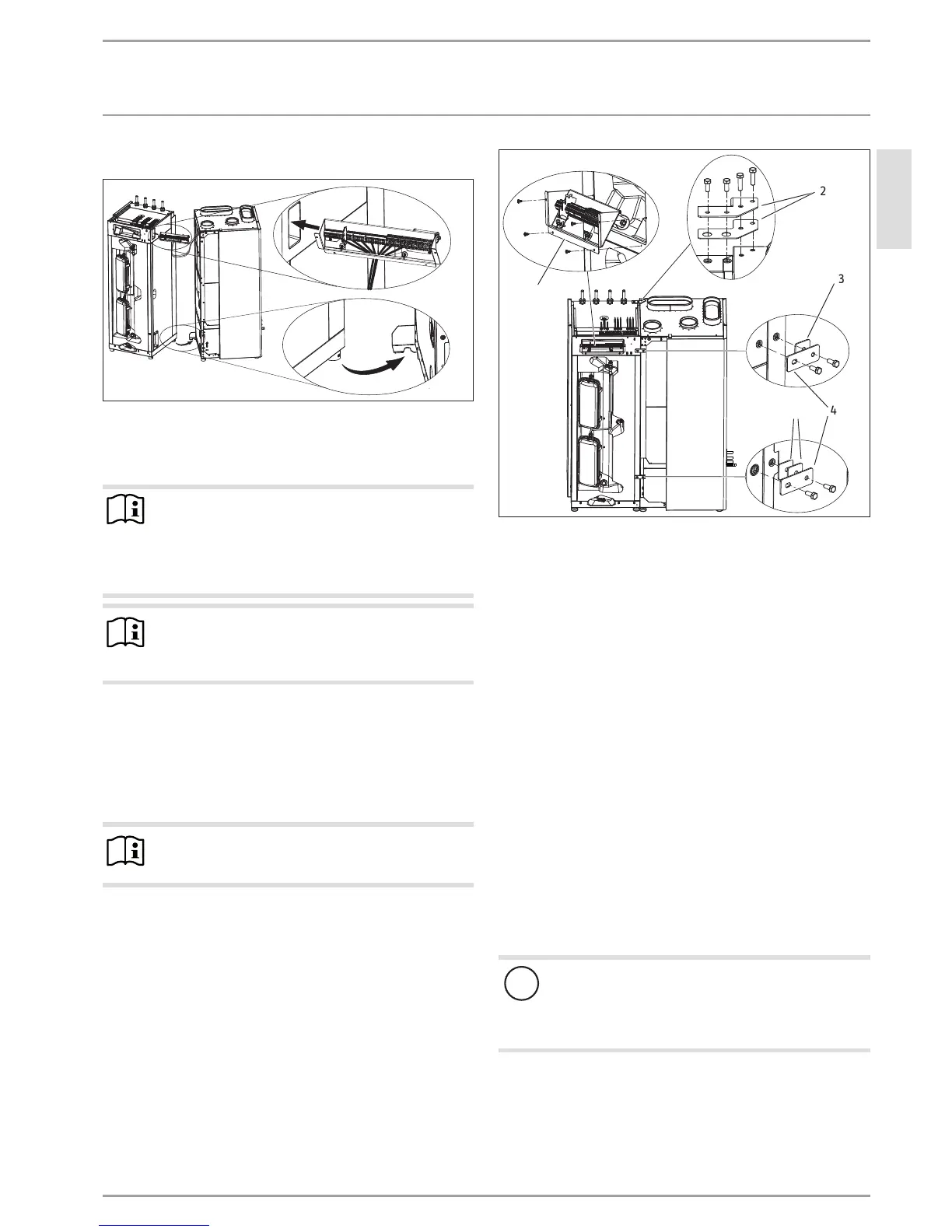

Inserting the terminal bracket into the cylinder module

26_04_01_0551

Push the terminal bracket through the aperture located at the

top r.h. side of the cylinder module.

Pushing the cylinder and the function modules together

Note

An air hose to capture the differential pressure runs

along the l.h. side of the function module. This air hose

must run inside the curved groove cut into the thermal

insulation.

Ensure that this air hose is seated correctly.

Note

The adjustable feet must not be fully screwed in, oth-

erwise you will not be able to push the joining bracket

between the bottom panel and the foot.

Push the cylinder module further towards the function mod-

ule, so that the rear r.h. adjustable foot of the cylinder mod-

ule is pushed into the recess in the joining bracket.

The lower joining bracket ensures that the cylinder module

is automatically pushed into its final position. Level the cyl-

inder module and the function module vertically to the same

height by turning the adjustable feet.

Note

The cylinder module drops 4 to 5mm when its cylinder

is filled.

Turning anti-clockwise exposes more of the adjustable feet, mean-

ing the appliance moves upwards. The cylinder module must be

snug against the function module.

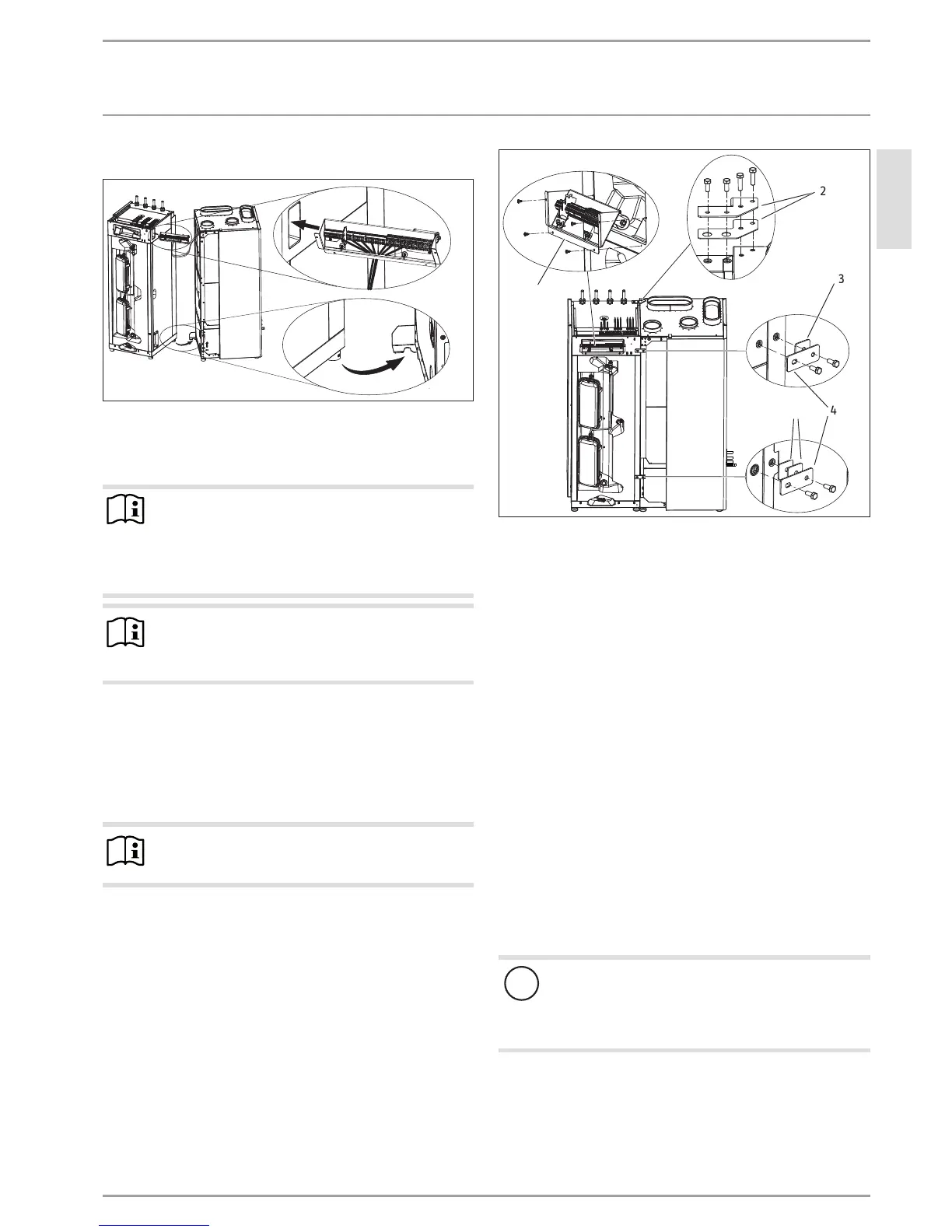

26_04_01_0560

1

2

4

3

3

1 Terminal bracket

2 Joining plates

3 Spacer

4 Horizontal locking bracket

Guide the terminal bracket forwards out of the cylinder

module.

Offer the terminal bracket up to the front of the cylinder

module frame. Ensure that the cables are positioned so that

the are free of stress/pressure.

Attach the terminal bracket to the cylinder module using four

screws.

Connection top back

Connect the function module and the cylinder module at

the top back by positioning joining plates and inserting two

screws each through the joining plate into the function mod-

ule and the cylinder module.

Fitting the horizontal locking bracket to the front

Connect the function module and cylinder module at the

front by securing one horizontal locking bracket each at the

top and bottom using screws. The spacers supplied enable

you to align the cylinder and function modules. Position a

spacer on the side of the function module, behind the upper

cross bolt and two spacers behind the lower cross bolt.

!

Material losses

Before filling, tighten the screws only lightly so that the

paint finish is not damaged when the cylinder module

moves down during filling. Tighten the screws after fill-

ing.

Loading...

Loading...