www.stiebel-eltron.com LWZ304-404 SOL | 17

INSTALLATION

Installation

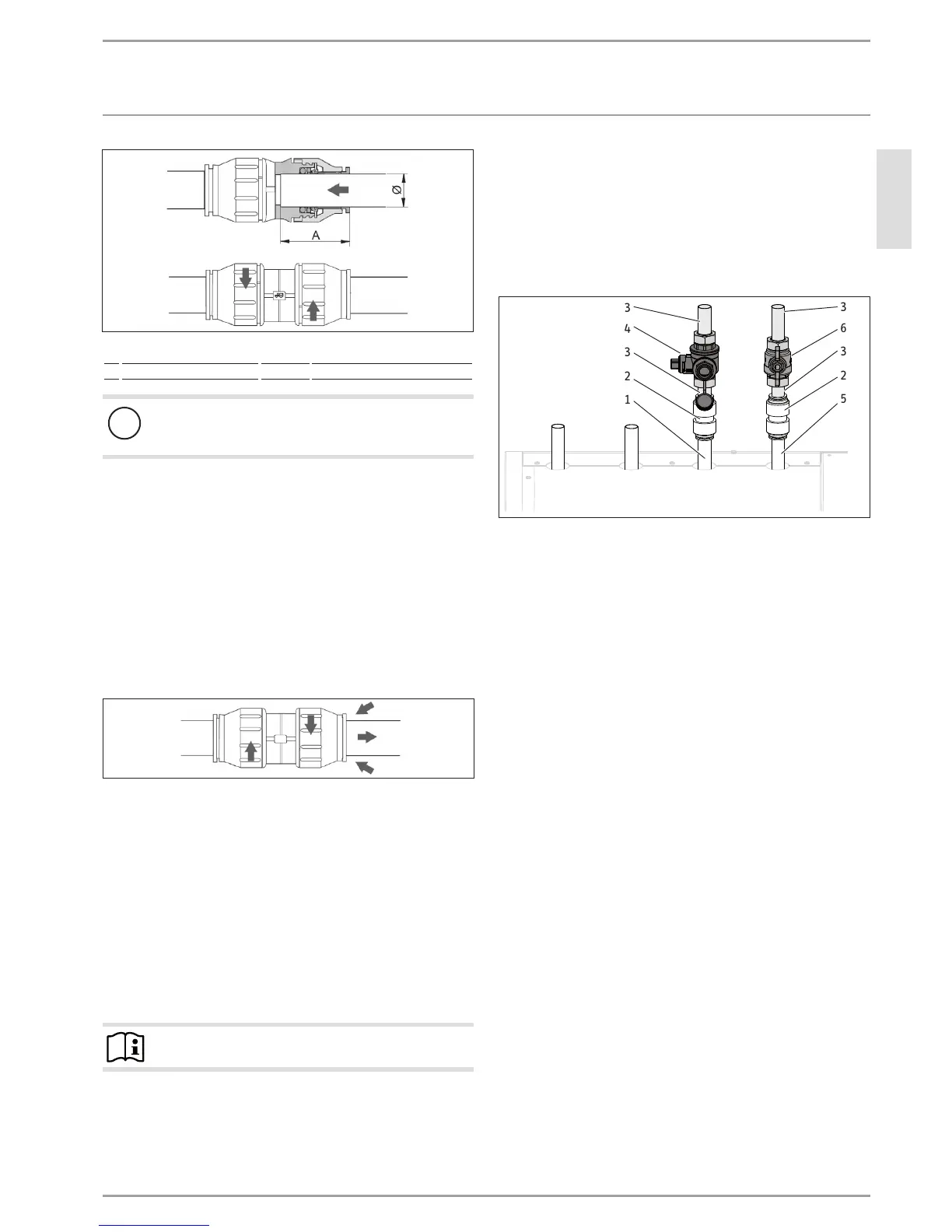

26_03_01_0693

Ø Tube diameter mm 22

A Insertion depth mm 38

!

Material losses

Pipe ends must be deburred.

Always use a pipe cutter to trim pipes.

Push the pipe through the O-ring into the push-fit connector

until it reaches the prescribed insertion depth.

Tighten the screw cap fully to the joiner body until fin-

ger-tight. This locks the push-fit connection.

Undoing the push-fit connection

If the push-fit connectors later need to be undone, proceed as

follows:

Turn the screw cap anti-clockwise until a there is a narrow

gap of approx. 2mm. Press the retainer back with your fin-

gers and hold on to it.

Pull out the inserted pipe.

26_03_01_0693

5.3.2 Connecting modules with push-fit connectors

Connect the pipes inside the function module to the push-fit

connectors that you previously attached to the cylinder mod-

ule pipes.

Refit the high limit safety cut-out retaining bracket from the

inside using the slots and secure the bracket.

5.4 Heating water connection

The heating system must be connected by a qualified contractor in

accordance with the water installation drawings, which are part of

the technical guides. You can use the push-fit connectors supplied

or ball valves to make the connection of the flow and return.

Note

Deburr the pipe ends.

A filter ball valve is provided for the return. Two union nuts and

two short flanged copper pipe ends are provided for fitting a ball

valve.

As a suitable point, install an air vent valve at the highest

point of the heating system.

Thoroughly flush the pipework before connecting the ap-

pliance. Foreign bodies such as welding pearls, rust, sand,

sealant, etc. can impair the operational reliability of the ap-

pliance, and can lead to the condenser becoming blocked.

Remove the protective caps from the heating flow and heat-

ing return connections.

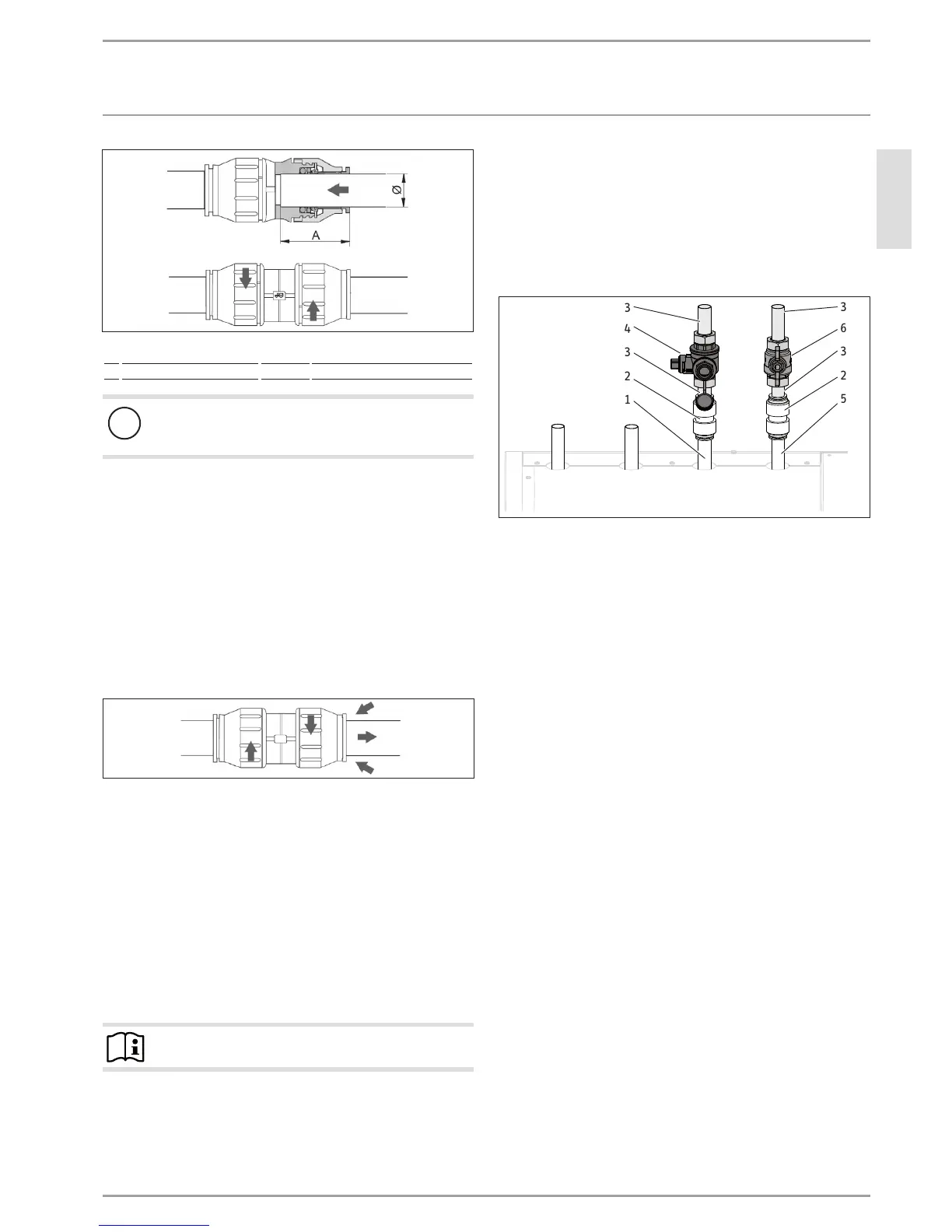

Heating return connection

1

2

3

4

3

5

2

3

6

3

26_04_01_0629

1 Heating return connection

2 Plug-in connector

3 Flanged pipe

4 Filter ball valve

5 Heating flow connection

6 Ball valve

Using a push-fit connector, connect one of the flanged pipes

supplied to the heating return connection.

Connect the filter ball valve to the flanged pipe end.

Reconnect a flared pipe to the end of the ball valve.

Connect the flanged pipe with a push-fit connector to the

heating circuit return.

Heating flow connection

Using a push-fit connector, connect one of the flanged pipes

supplied to the connection for the heating flow.

Connect a ball valve to the flanged pipe end.

Connect a flanged pipe to the other side of the ball valve.

Connect the flanged pipe with a push-fit connector to the

heating circuit flow.

Thermal insulation

Provide thermal insulation in accordance with current

regulations.

Water quality

Carry out a fill water analysis before the system is filled. This may,

for example, be requested from the relevant water supply utility.

To avoid damage as a result of scaling, it may be necessary to

soften or desalinate the fill water. The fill water limits specified

in chapter "Specification/ Data table" must always be observed.

Recheck these limits 8-12 weeks after commissioning and as

part of the annual system maintenance.

Loading...

Loading...