www.stiebel-eltron.com LWZ304-404 SOL | 9

INSTALLATION

Preparations

4.2 Air routing

Prevent air stream "short circuits". The air intake and discharge

apertures in the external walls should be arranged around cor-

ners. When installing the air intake and discharge apertures on

the same side of the building, maintain a minimum clearance of

at least 2m between apertures. Where that is impossible, create

a separation between the air streams, e.g. by a separating wall or

shrubs between the intake and discharge apertures.

Never align the apertures toward neighbouring living room or

bedroom windows.

4.3 Sound emissions

Sound insulation for rooms adjacent to the installation room

When the appliance is in operation, sound emissions can occur

which may be a nuisance in adjacent rooms. This is especially the

case if the installation room adjoins a living room or bedroom. To

prevent noise pollution, sound attenuation measures are neces-

sary, e.g. sound attenuation of a higher standard for the internal

wall. Pipe fixings and wall outlets must have anti-vibration insu-

lation. For the wall between the installation room and the living

space, we recommend a wall structure that ensures the following

level of sound attenuation:

- 45 dB(A) for adjacent living rooms and bedrooms

- 40 dB(A) for other rooms

Doors should be of sound safety category SK3.

If the appliance backs onto an adjacent room, we recommend the

following level of sound attenuation:

- 55 dB(A) for adjacent living rooms and bedrooms

- 50 dB(A) for other rooms

A passage to the neighbouring room is not recommended.

The floor between the installation room and living areas must

have carefully applied anti-vibration separation. Ensure that no

pipes are routed on or in the wall and that the air ducts have

anti-vibration separation.

If the appliance installation room is included in the building ven-

tilation system, an extract air valve and supply air valve must be

planned in. To avoid the need for an overflow aperture in the

door, the supply air and extract air flow rates must be balanced.

Note

The appliance can seem loud if operated in an unfinished

building without doors. This is because the fixtures and

fittings are not yet in place which will provide sound at-

tenuation; once the building is occupied this should no

longer occur.

Sound attenuation 45dB(A)

Sound attenuation of 45dB(A) can be achieved using, for ex-

ample, a lightweight wall of timber frame construction with full

insulation. The cross-section of the timber supports should be

60x60mm. The wall must have plasterboard panelling on both

sides, with a thickness of 12.5 mm on one side and 10 mm on the

opposite side.

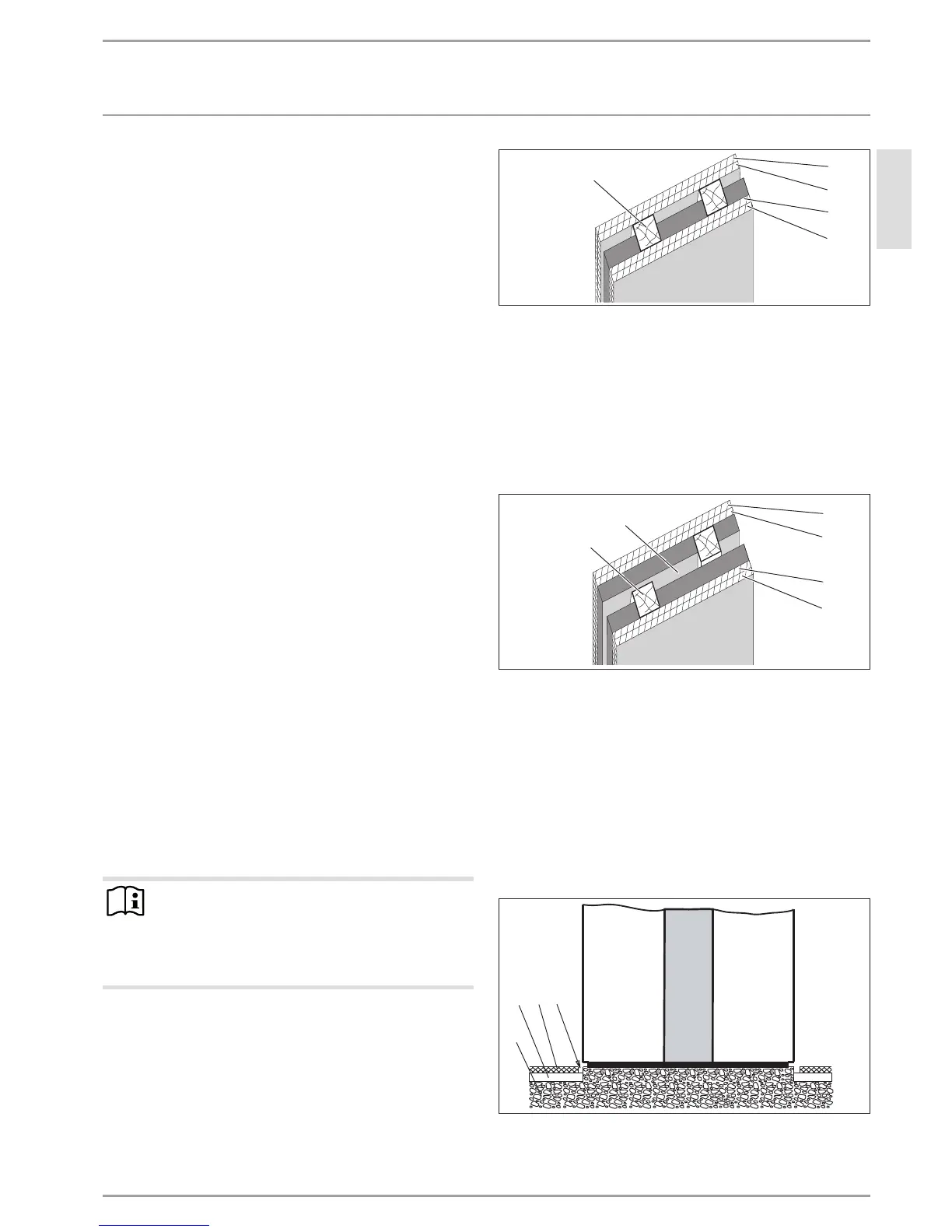

2

1

3

3

2

D0000047127

1 Timber supports 60 x 60 mm

2 Gypsum fibre board 12.5 mm

3 Gypsum fibre board 10 mm

Sound attenuation 55dB(A)

Sound attenuation of 55dB(A) can be achieved using, for exam-

ple, a lightweight twin wall of timber frame construction with

full insulation and 30mm parting line. The cross-section of the

timber supports should be 60x60mm. The wall must have 12.5

mm plasterboard panelling on both sides.

3

1

3

3

3

2

D0000047126

1 Parting line 30 mm

2 Timber supports 60 x 60 mm

3 Gypsum fibre board 12.5 mm

Anti-vibration separation

With the anti-vibration feet, it is possible to install the appliance

on floating screed, as long as this has been applied correctly. If

necessary provide separation.

If the appliance is positioned on a wooden beam ceiling, you must

take special steps to prevent structure-borne noise transmission.

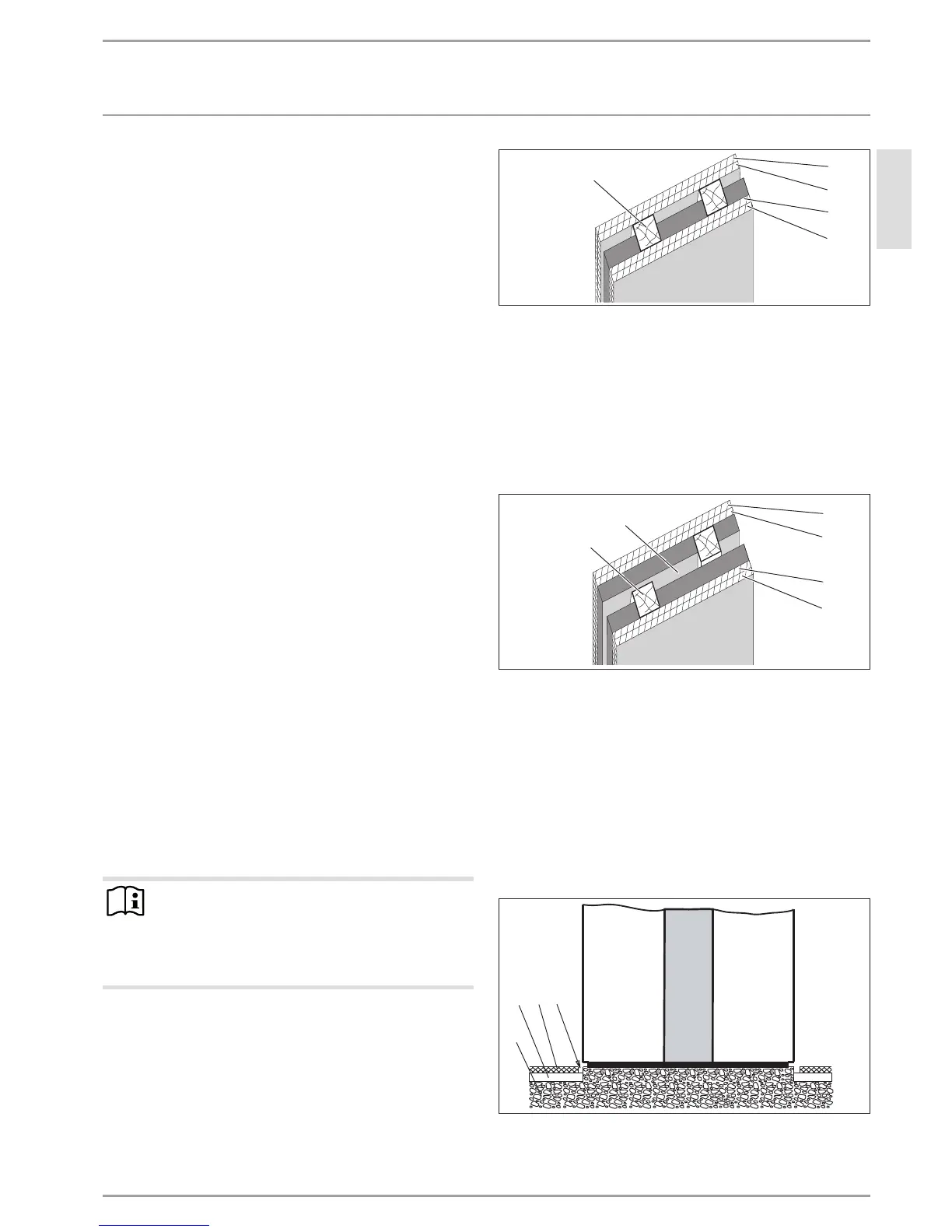

Installation on foundations

3

42

1

26_04_01_0290

1 Concrete base

2 Impact sound insulation

3 Floating screed

4 Screed recess

Loading...

Loading...