OPERATION

Operation

ENGLISH

www.stiebel-eltron.com LWZ 304-404 SOL | 11

- HEAT M BOOST DHW TTL: Amount of heat that has been

transferred by the electric emergency/booster heater to the

DHW cylinder since the appliance was commissioned.

- HEAT M RECOVERY DAY: Amount of heat that was recovered

from the ventilation system on this day.

- HEAT M RECOVERY TTL: Amount of heat that has been re-

covered from the ventilation system since the appliance was

commissioned.

- HM SOLAR HTG DAY: Amount of heat that was transferred by

the solar thermal system to the heating circuit on this day.

- HM SOLAR HTG TOTAL: Amount of heat that has been trans-

ferred by the solar thermal system to the heating circuit since

the appliance was commissioned.

- HM SOLAR DHW DAY: Amount of heat that was transferred by

the solar thermal system to the DHW cylinder on this day.

- HM SOLAR DHW TOTAL: Amount of heat that has been trans-

ferred by the solar thermal system to the DHW cylinder since

the appliance was commissioned.

- HM COOLING TOTAL: Amount of heat absorbed by the appli-

ance via its evaporator from the rooms.

- PRESSURE HTG CIRC: This parameter indicates the pressure

inside the heating circuit.

- WATER FLOW RATE

4.7.10 Heating

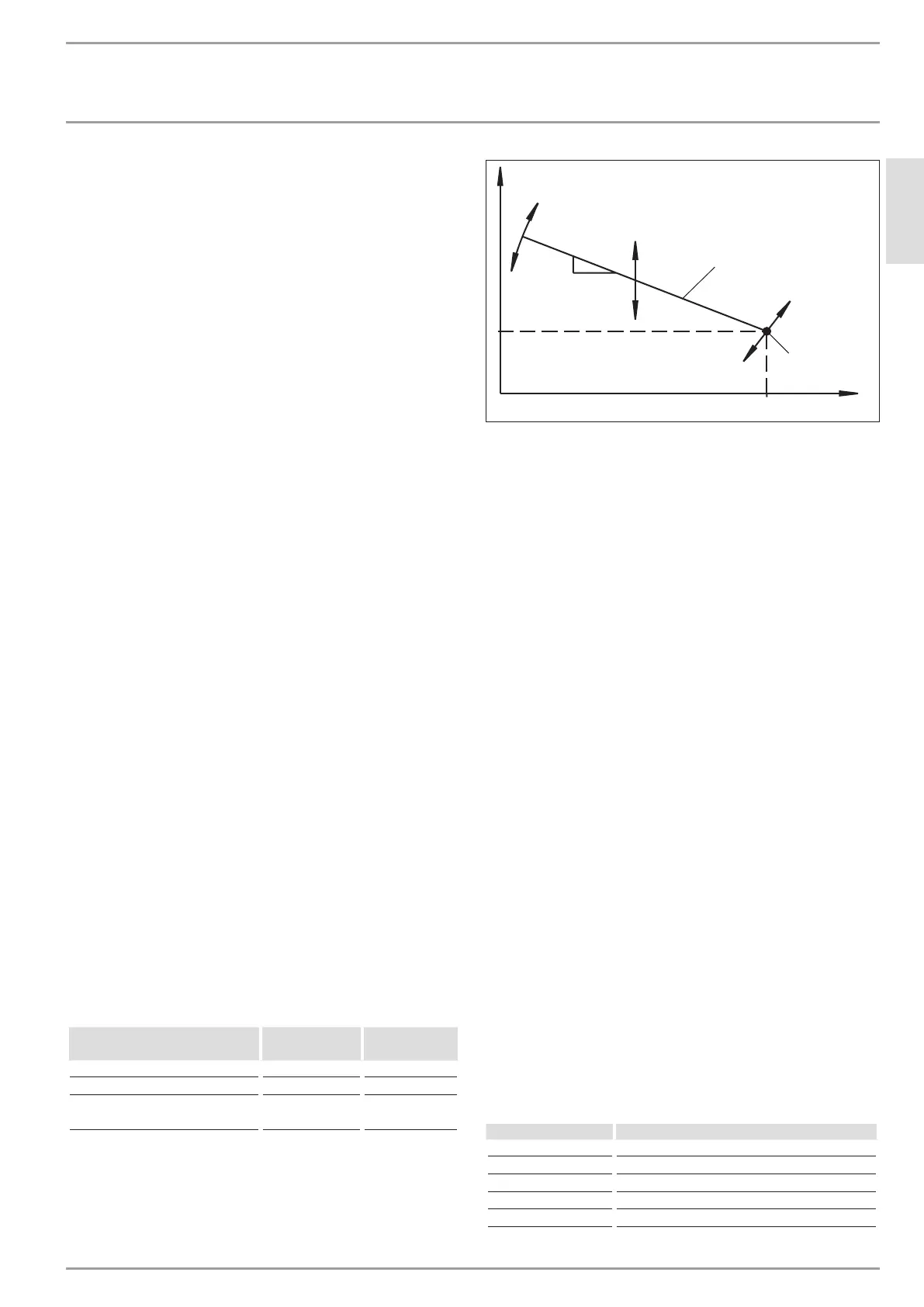

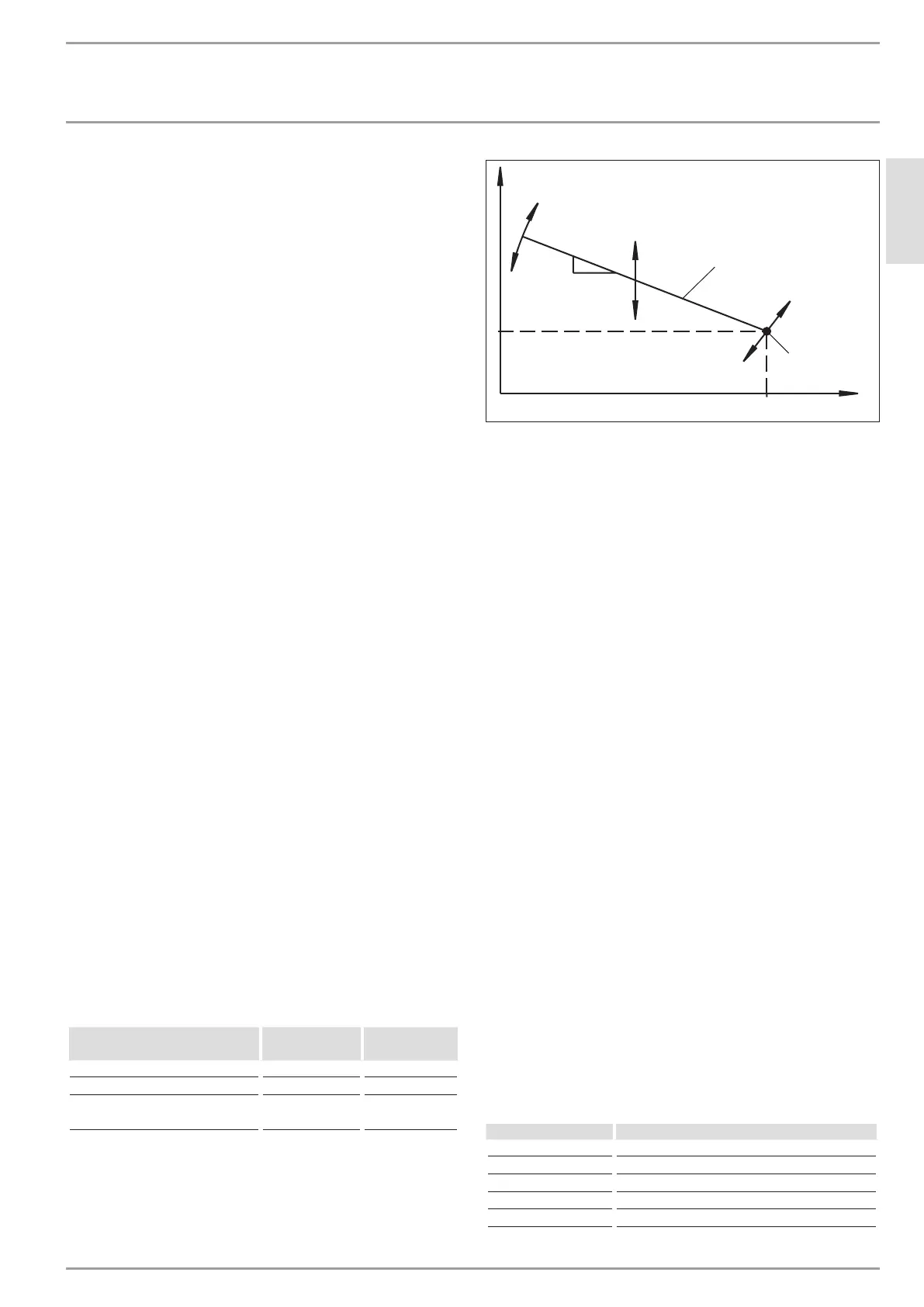

This parameter enables you to set one heating curve each for

heating circuits 1 and 2. The room temperature will only remain

constant irrespective of the outside temperature if the correct

heating curve has been selected for the relevant type of building.

Selecting the correct heating curve is therefore vitally important.

The more precisely the heating curve is set, the more economically

the appliance works. Try therefore to optimise your heating curve.

Reduce the current heating curve until the flow temperature is

just sufficient for heating. The target is as flat a heating curve as

possible.

f Fully open thermostatic valves (remove head) in a lead room,

for example living room or bathroom.

f At different outside temperatures, adjust the heating curve so

the required temperature is set in the lead room (living room

or bathroom). Now the room temperature in these rooms is

controlled with the heating curve (see next diagram).

Standard values to begin with:

Parameter Underfloor

heating system

Radiator heat-

ing system

GRADIENT (P13) 0.4 0.8

LOW END (P14) 3 K 10 K

ROOM TEMPERATURE DAY

(P01)

20 °C 20 °C

1

3

2

4

5

Y

X

6

26�04�01�0297

7

1 Gradient influence

Gradient = Y/X

= Heating circuit temperature change/Outside temperature

change

2 Low end offset influence

3 Heating curve

4 Set room temperature influence

5 Low end

6 Outside temperature in °C

7 Set heating circuit temperatures in °C

HEATING CURVE gradient

The gradient [MENU/HEATING] determines the extent to which a

change in the outside temperature effects a rise in the flow tem-

perature. Typical problem: Increase the gradient if the room tem-

perature is too low at low outside temperatures (approx. -10°C).

Low end offset of the heating curve

By changing the parameter

LOW END, you effect a parallel offset

of the heating curve. Typical applications are explained in chapter

"Troubleshooting".

ROOM INFLUENCE

If you want to influence the heating curve through the room tem-

perature, install an auxiliary programming unit "FESComfort" in

your home. For parameter

ROOM INFLUENCE [MENU/HEATING/

HC1 or HC2], enter a value >0. The heating curve is then changed

by this value (room temperature deviation * room influence *

heating curve gradient).

FLOW PROPORTION

Flow means the pipework that supplies heating water to the heat-

ing system. The return carries the cooled water from the heating

system to the heating system. With parameter

FLOW PROPOR-

TION

[MENU/HEATING], you determine whether your heating sys-

tem should function as a flow or return temperature-controlled

system.

Flow proportion Effect

0 Heating system with return temperature control

100 Heating system with flow temperature control

50 Spread control (50% return and 50% flow control)

30 Spread control (70% return and 30% flow control)

80 Spread control (20% return and 80% flow control)

296066-38500-9030_LWZ_304-404_SOL_Bedienung_en.indb 11 21.07.2015 12:03:49

Loading...

Loading...