24 |WPF | WPF cool www.stiebel-eltron.com

INSTALLATION

Preparations

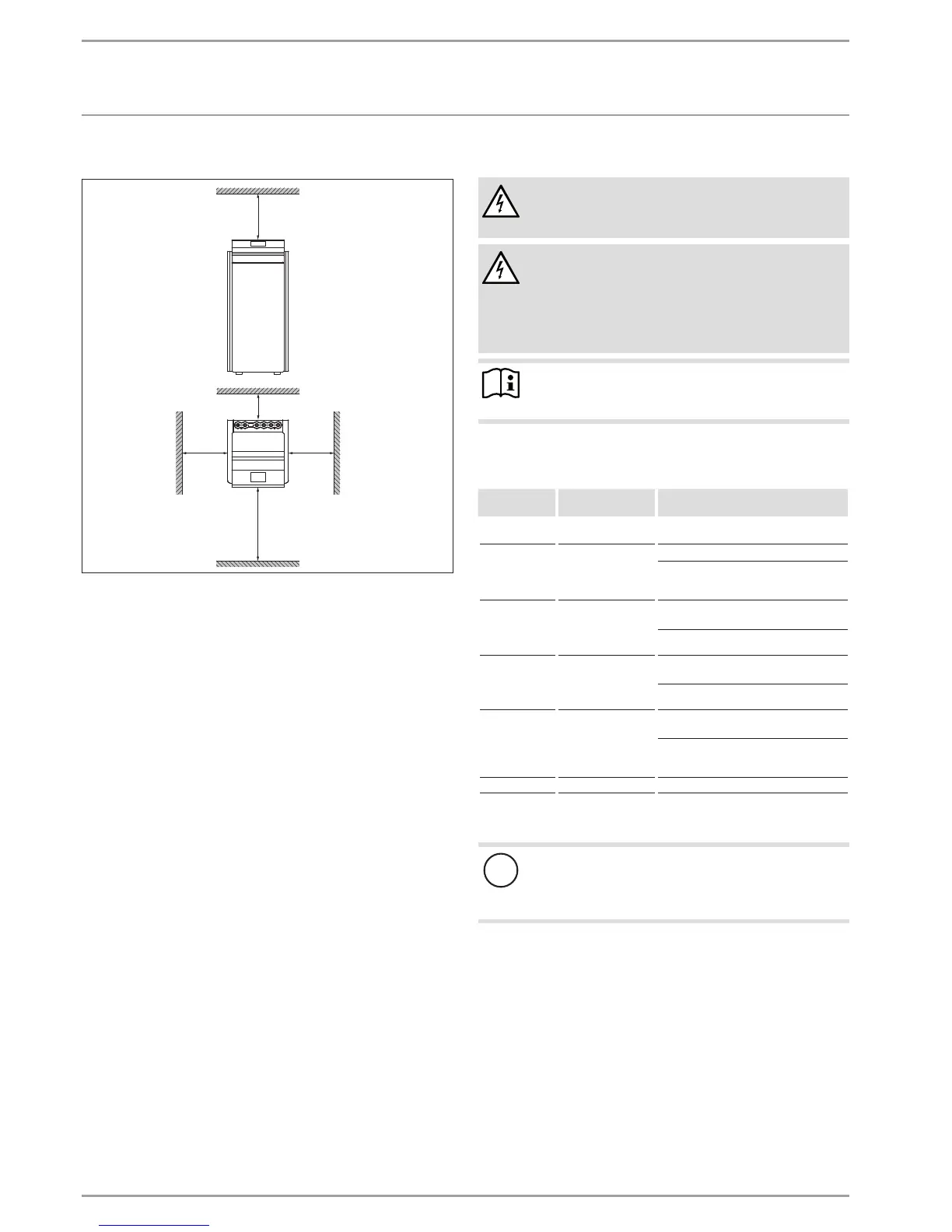

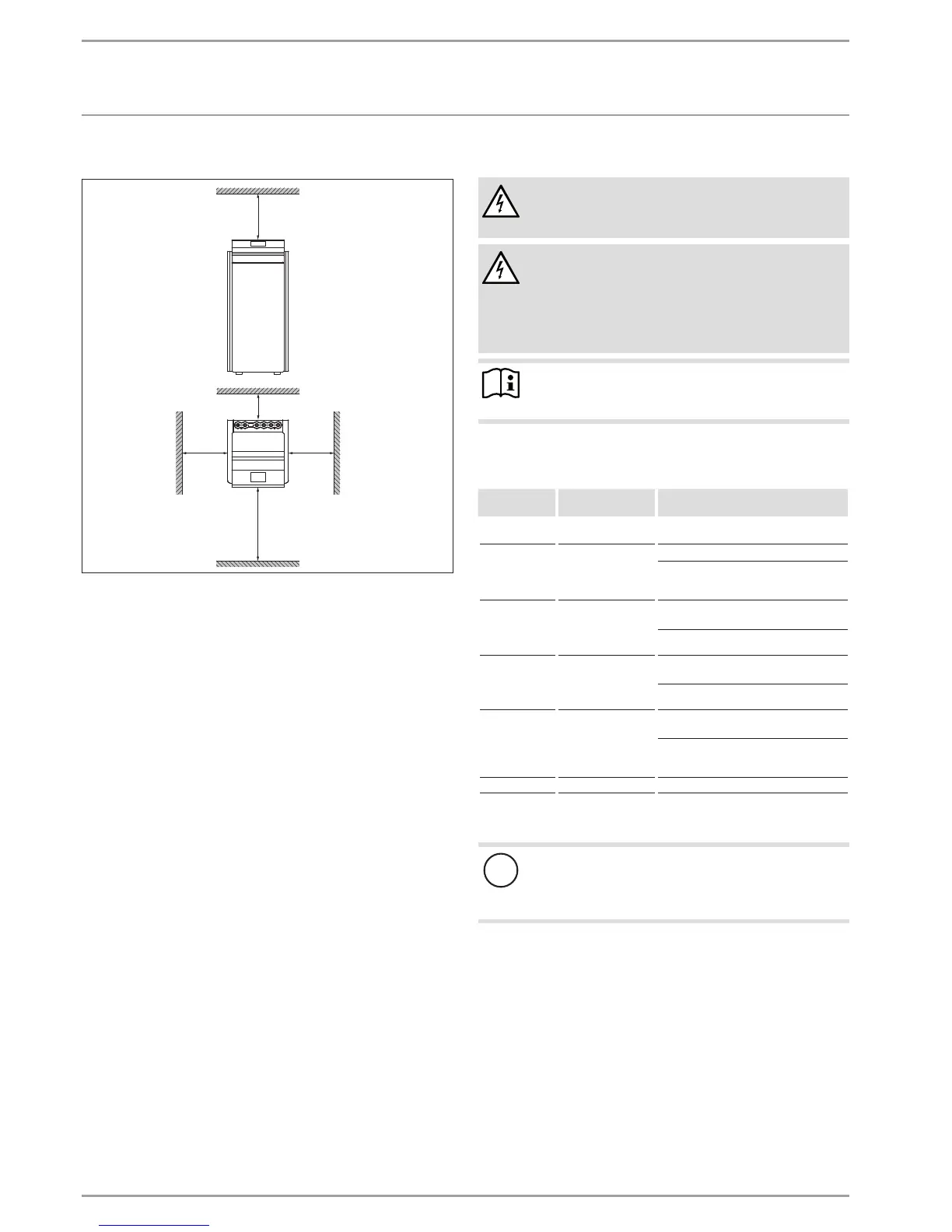

10.4.1 Minimum clearances

≥500

≥50

≥500

≥500

≥1000

D0000034469

Maintain the minimum clearances to ensure trouble-free op-

eration of the appliance and facilitate maintenance work.

10.1 Electrical installation

DANGER Electrocution

Carry out all electrical connection and installation work

in accordance with national and regional regulations.

DANGER Electrocution

Only use a permanent connection to the power supply.

Ensure that the appliance can be separated from the

power supply by an isolator that disconnects all poles

with at least 3mm contact separation. This requirement

can be met with contactors, circuit breakers, fuses, etc.

Note

The specified voltage must match the mains voltage. Ob-

serve the type plate.

Install cables with the following cross-sections in accordance with

the respective fuse rating:

Fuse/MCB

rating

Assignment Cable cross-section

C 16 A Compressor

(three phase)

2.5 mm²

B 16 A

Electric emergency/

booster heater (BH)

(three phase)

2.5 mm²

1.5 mm² with only two live cores and

routing on a wall or in an electrical con-

duit on a wall.

C 16 A

Compressor

WPF 05 S / 07 S

(single phase)

1.5 mm² for open routing. Note the type

of routing!

2.5 mm² for routing through a

wall. Note the type of routing!

C 25 A

Compressor

WPF 10 S / 13 S

(single phase)

4.0 mm² for open routing. Note the type

of routing!

6.0 mm² for routing through a

wall. Note the type of routing!

B 16 A

Electric emergency/

booster heater (BH)

(single phase)

2.5 mm² for routing through a

wall. Note the type of routing!

1.5 mm² when routing a multi core line

on a wall or in an electrical conduit on

a wall.

B 16 A Control unit 1.5 mm²

The electrical data is provided in the chapter "Specification / Data

table".

!

Material losses

Provide separate fuses/MCBs for the two power circuits

of the compressor and the electricemergency/booster

heater.

Loading...

Loading...