www.stiebel-eltron.com WPF | WPF cool | 35

INSTALLATION

Commissioning

Reset the high limit safety cut-out by pressing the reset

button.

13.1.5 Power supply

- Have you correctly connected the power supply?

- The compressor turns in the right direction if, when volt-

age is applied to the heat pump power supply (mains), no

fault message appears in the display. If the fault message

NO OUTPUT appears, reverse the rotational direction of the

compressor.

13.2 Heating curve adjustment during

commissioning

The efficiency of a heat pump decreases as the flow temperature

rises. Therefore adjust the heating curve with care. A heating

curve that is set too high leads to the zone and thermostatic valves

closing and the minimum flow rate required for the heating circuit

may not be achieved.

The following steps will help you to adjust the heating curve cor-

rectly:

Fully open thermostatic or zone valves in a lead room (e.g.

living room or bathroom).

We do not recommend installing thermostatic or zone valves

in the lead room. Control the temperature for these rooms

via remote control.

At different outside temperatures (e.g. -10 °C and + 10 °C),

adjust the heating curve so the required temperature is set in

the lead room.

Standard values for the start:

Parameter Underfloor heating

system

Radiator heating

system

Heating curve 0.4 0.8

Control dynamic 10 10

Comfort temperature 20°C 20°C

If the room temperature in spring and autumn is too low (approx.

10 °C outside temperature), the COMFORT TEMPERATURE param-

eter must be raised.

Note

If no remote control is installed, raising the COMFORT

TEMPERATURE parameter leads to a parallel offset of the

heating curve.

If the room temperature is not high enough at low outside tem-

peratures, increase the HEATING CURVE parameter.

If the parameter HEATING CURVE has been raised, adjust the zone

valve or thermostatic valve in the lead room to the required tem-

perature at high outside temperatures.

Note

Never reduce the temperature in the entire building by

closing all zone or thermostatic valves, but by using the

setback programs.

13.3 Commissioning menu

Note

All menu options are protected by a code and can only be

viewed and adjusted by a qualified contractor.

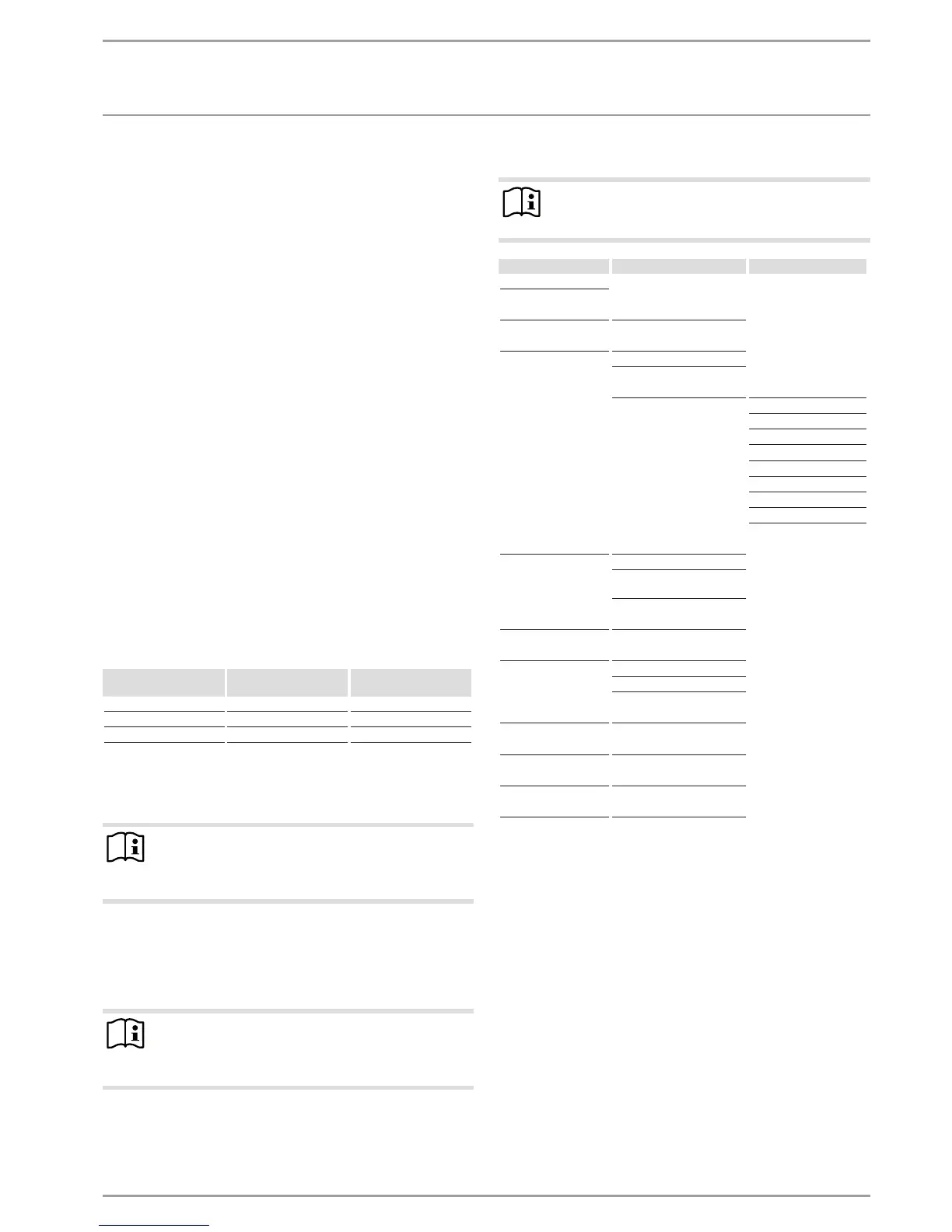

Level 2 Level 3 Level 4

ENTER CODE

LANGUAGE ENGLISH

SOURCE SOURCE TEMPERATURE MIN

BRINE PUMP RATING

SOURCE MEDIUM ETHYLENE GLYCO

POTASSIUM CARBONATE

EXTRACT MODULE 0

EXTRACT MODULE 30

EXTRACT MODULE 60

EXTRACT MODULE 120

EXTRACT MODULE 180

WATER

GROUNDWATER MODULE

HEATING CNTRL DYNAMIC

HP SENSOR MAX

HEATING CIRCT PUMP

RATING

DHW DHW CIRCUIT PUMP RATING

COMPRESSOR IDLE TIME

SINGLE PHASE OPERATION

QUICK START

EMERGENCY OPR ON / OFF

HEAT PUMP RESET ON / OFF

FAULT LIST RESET ON / OFF

SYSTEM RESET ON / OFF

13.3.1 Enter code

Enter the correct four-digit code to change parameters. The fac-

tory-set code is 1000

.

13.3.2 Language

Here you can select the menu language.

Loading...

Loading...