STIHL 009, 010, 011 18

3.8 Leakage Testing the

Crankcase

Defective oil seals and gaskets or The crankcase can be checked

accucracks in castings are the usual rately for leaks with the carburetor/

causes of leaks. Such faults allow crankcase tester and the vacuum

supplementary air to enter the engine pump.

and upset the fuel-air mixture.

This makes adjustment of the

prescribed idle speed difficult or even

impossible. Moreover, the transition

from idle speed to part or full throttle

is not smooth.

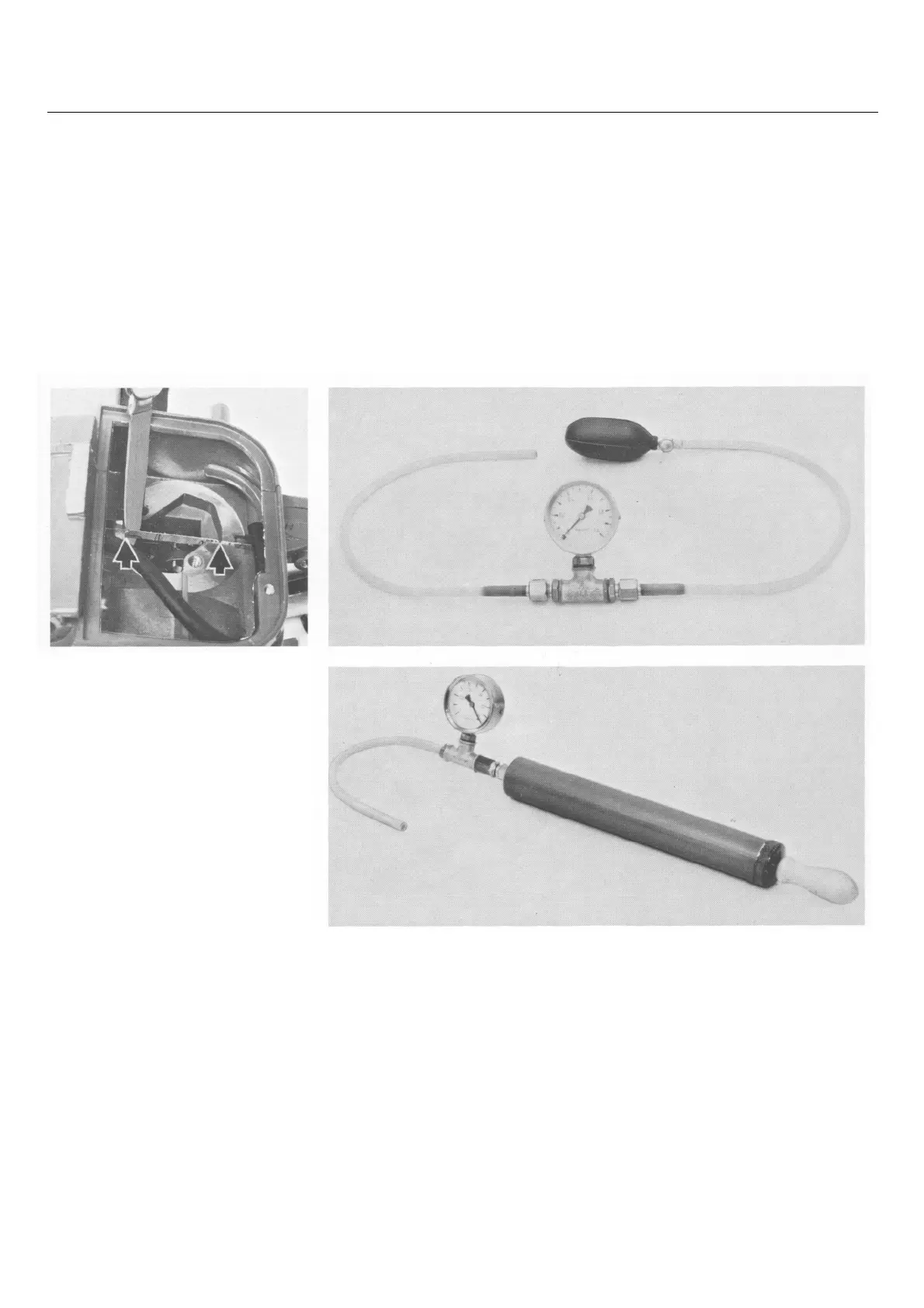

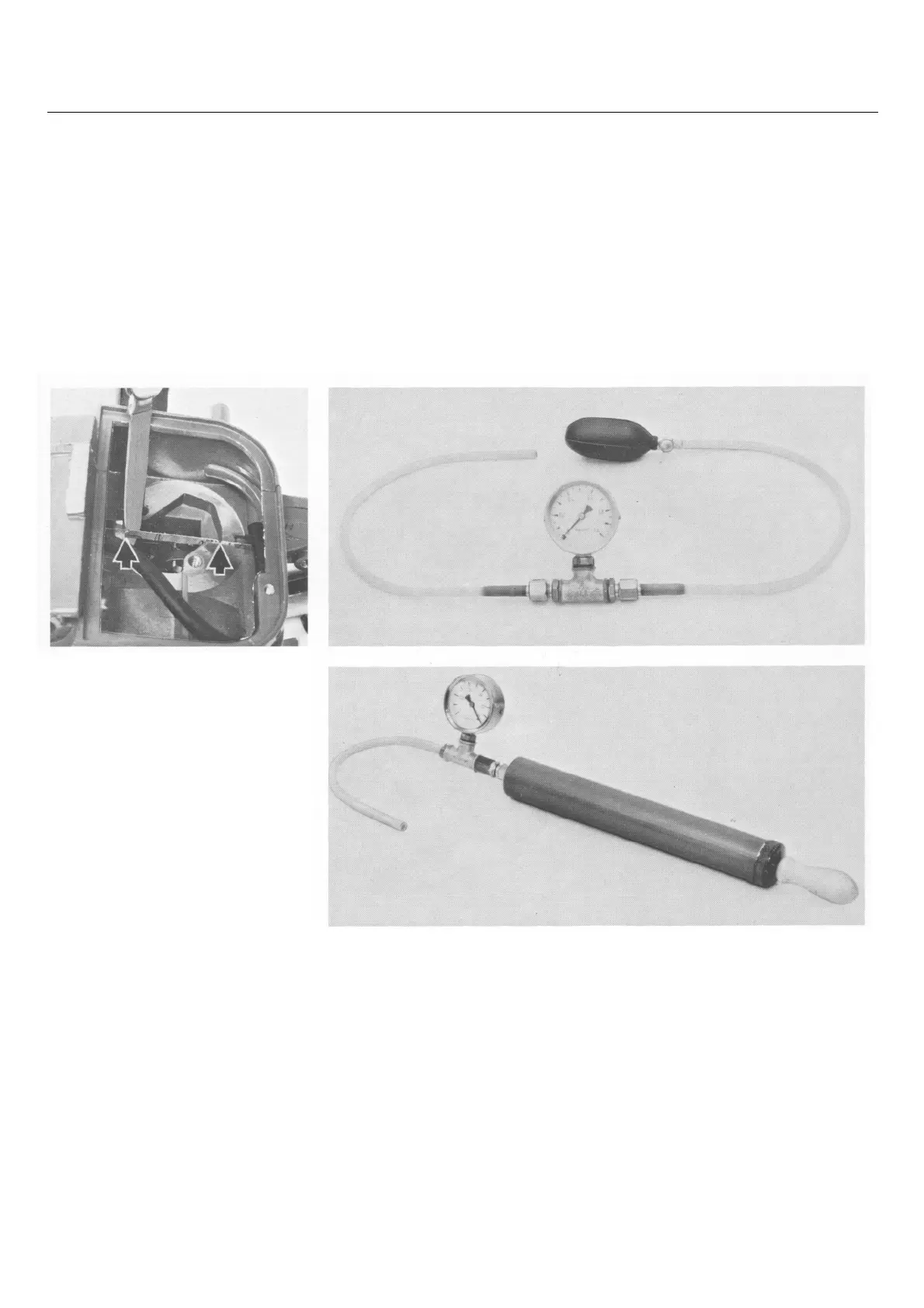

Top:

Carburetor and crankcase tester 1106 850 2900

Bottom:

Removing gasket web at inlet port Vacuum pump 0000 850 3500

Then insert and tighten down the

flat head screws to a torque of

4 - 5 Nm (0.4 - 0.5 kpm).

Reassemble all remaining parts by

reversing the disassembly

sequence. Carry out crankcase

leakage test (3.8) and check

ignition timing (4.5.2) before final

assembly.

Important: The web of the

crankcase gasket across the inlet

port must becut away before

fitting the diaphragm.

Loading...

Loading...