© STIHL Inc., Virginia Beach, VA 2013 US/STR

confidential

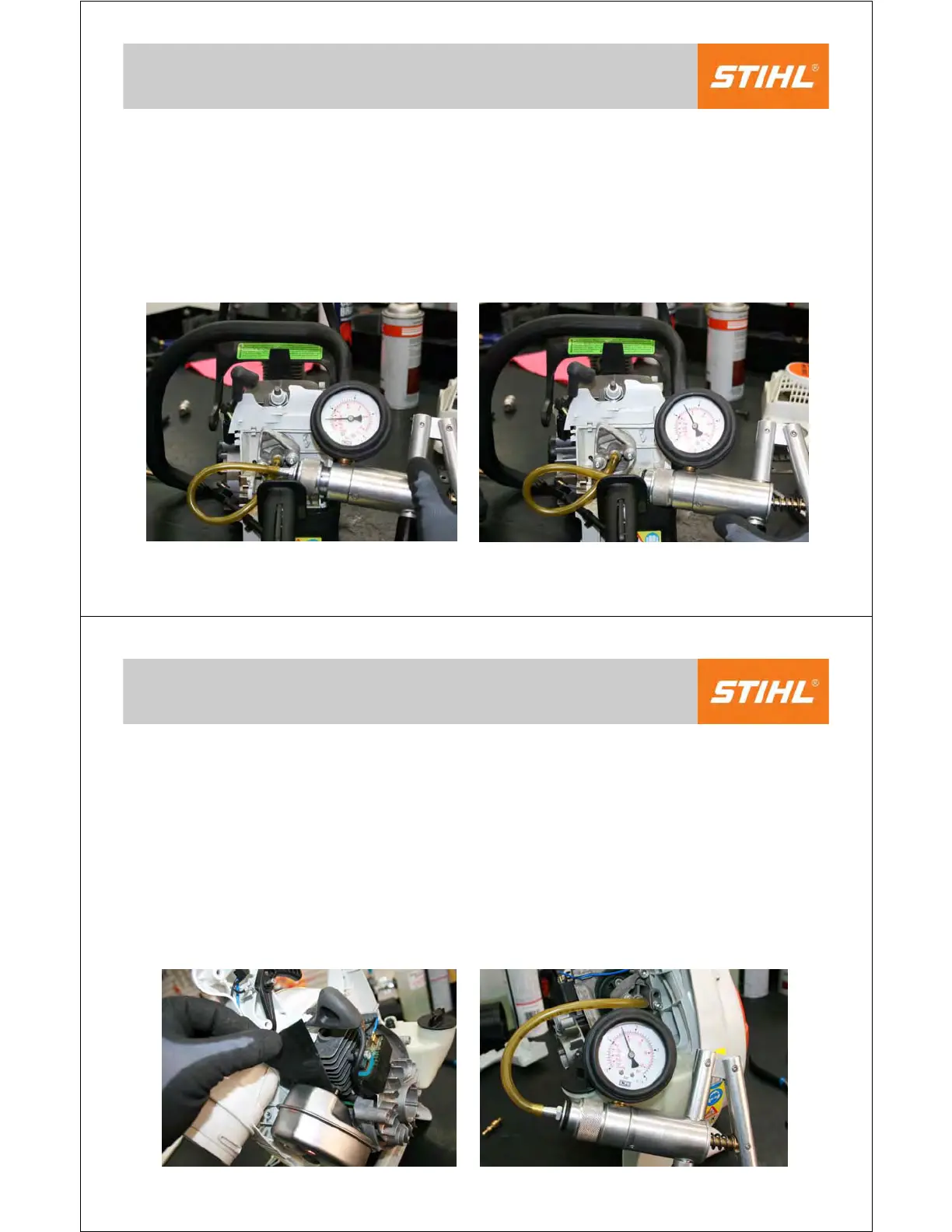

26. Vacuum and Pressure Test of Crankcase

Use the tester to pull a 0.5 bar vacuum; it should hold steady

or not leak back to 0.3 bar within 20 seconds

Rotate the crankshaft back and forth while the crankcase is

under vacuum to verify that the seals are holding properly

Pump 0.5 bar of pressure into the engine and it should hold

steady for at least 20 seconds

© STIHL Inc., Virginia Beach, VA 2013 US/STR

confidential

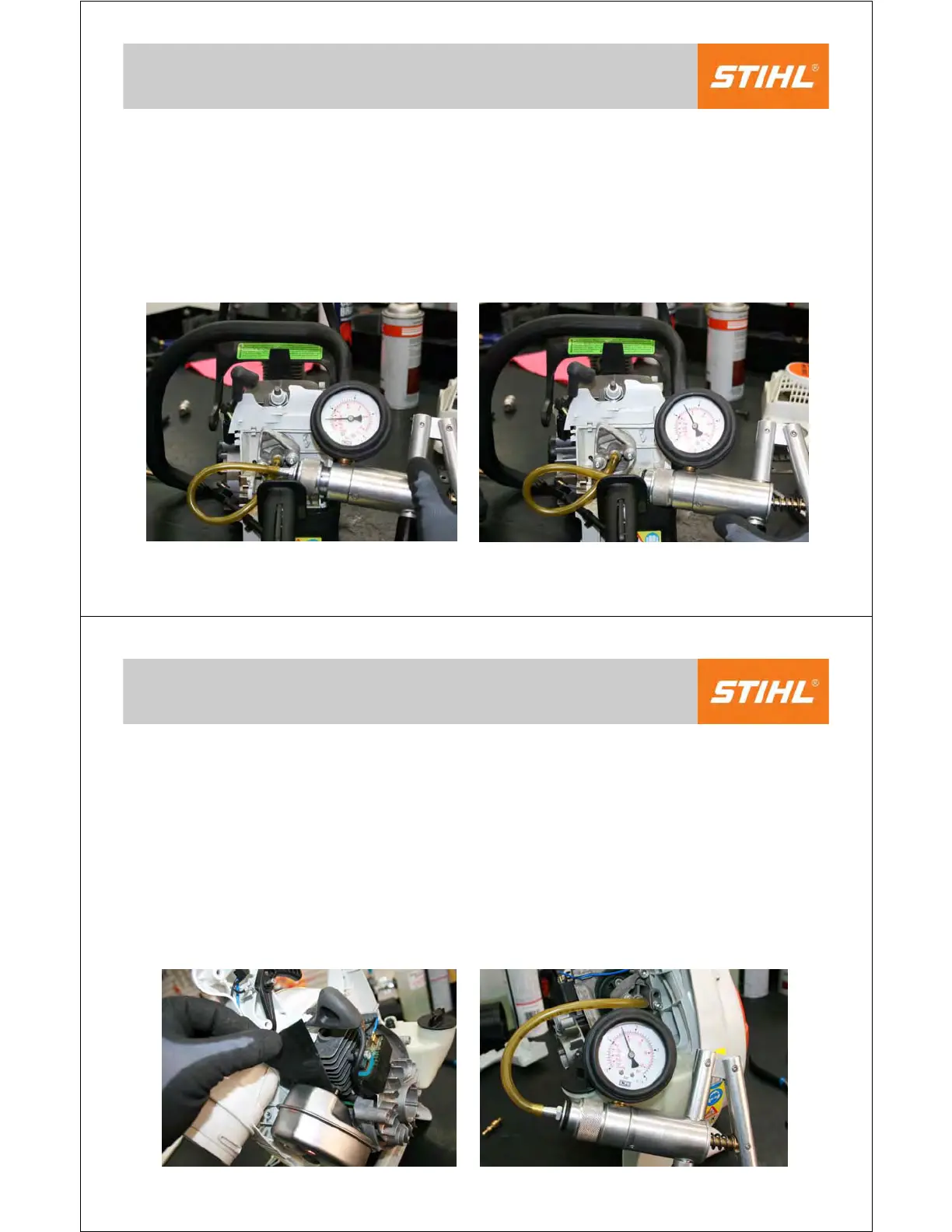

Pressure Test Results

If the unit fails the pressure test check obvious things first, such

as the rubber sealing plate on the exhaust and the spark plug,

by spraying with soapy water and looking for bubbles

If they are sealing properly then the engine may need to be

taken apart far enough to be able to check the crankshaft seals

and the seal between the cylinder and the crankcase

If an engine leaks under vacuum but holds under pressure it is

most likely a crankshaft seal

Loading...

Loading...