25MS 210, MS 230, MS 250

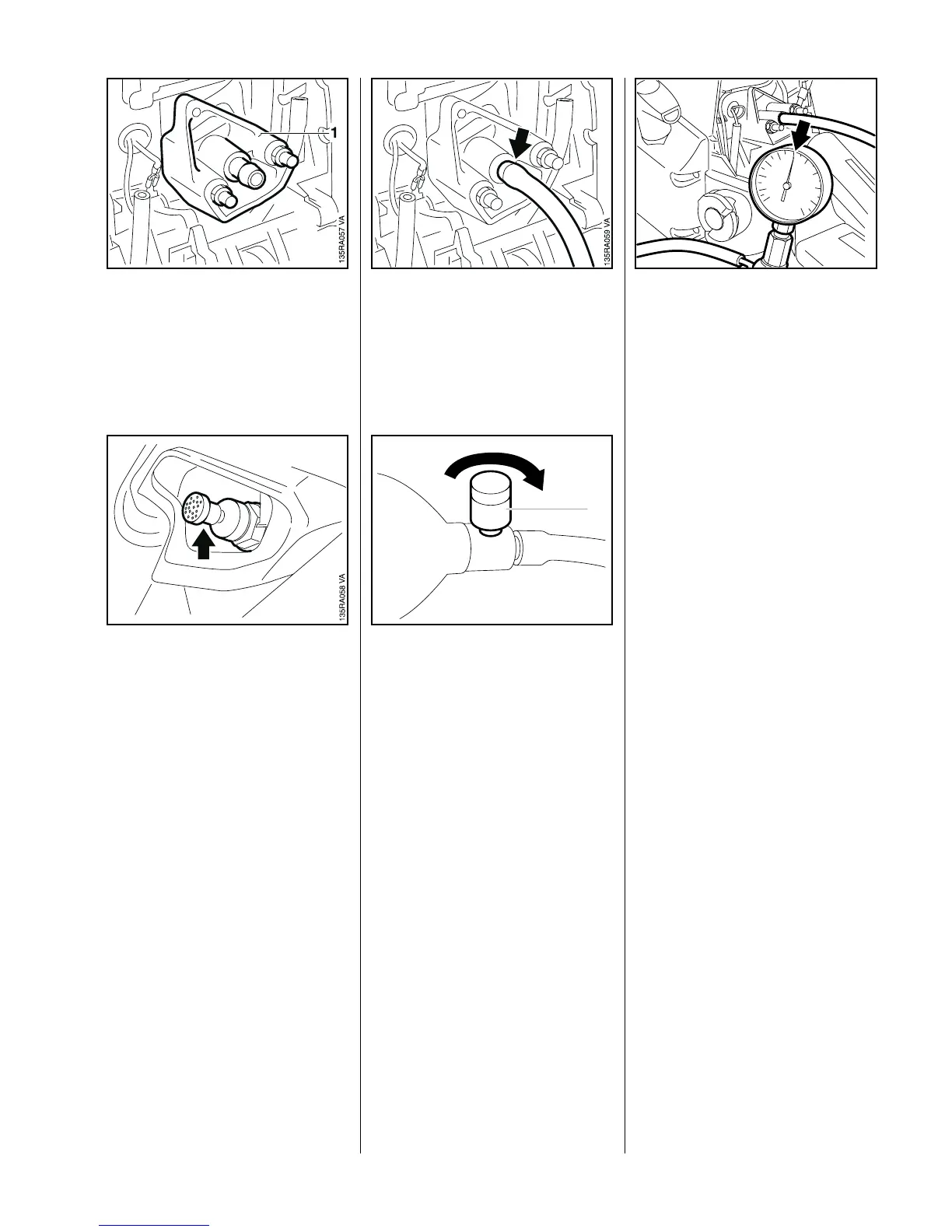

: Fit the test flange (1)

1118 850 4200 in place of the

carburetor.

: If decompression valve is fitted,

pull out the button.

– Check that spark plug is properly

tightened down.

– Perform leakage test with tester

1106 850 2905 and vacuum

pump 0000 850 3501.

– Carry out preparations –

b 6.2.1.

: Connect pressure hose of tester

1106 850 2905 to nipple on test

flange.

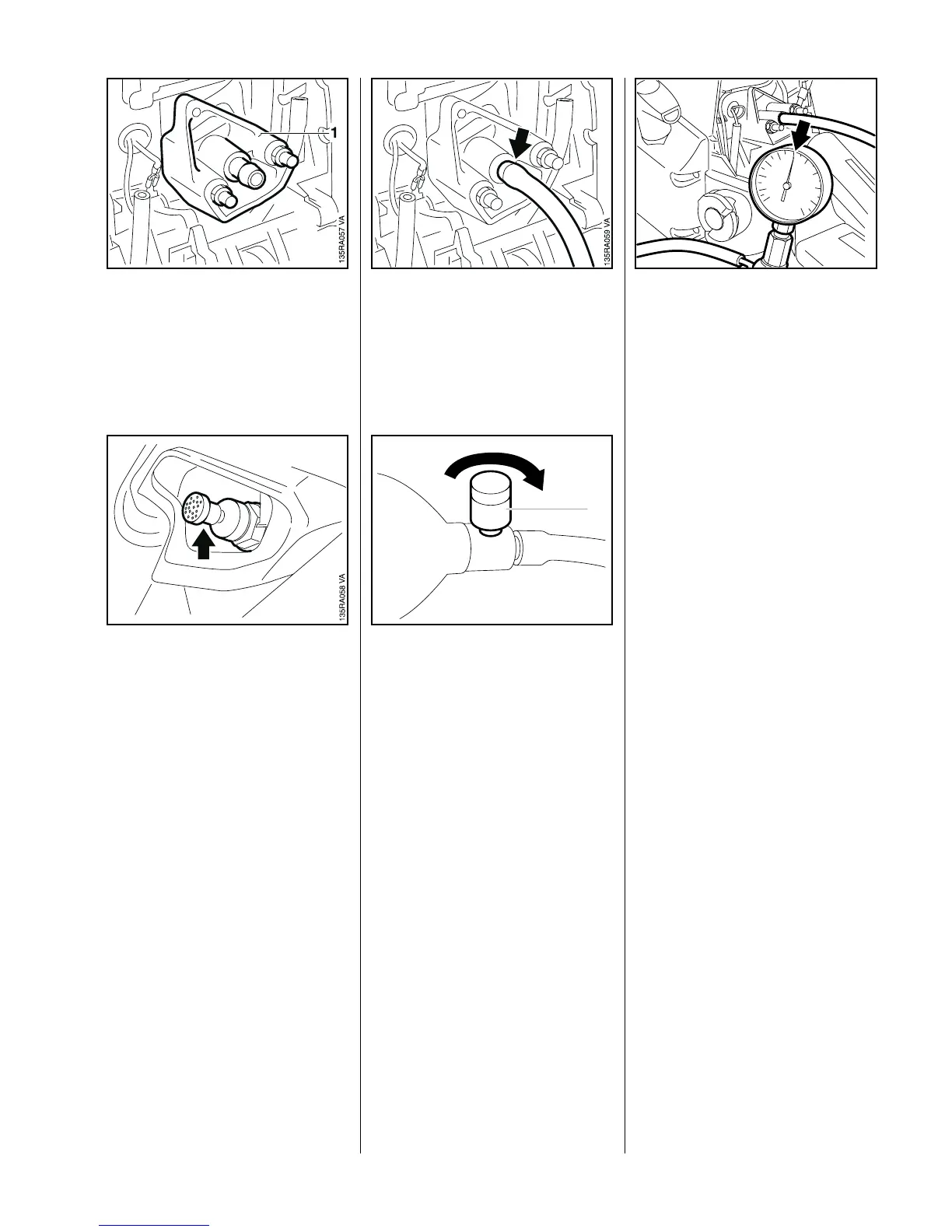

: Close the vent screw (1) on the

rubber bulb.

– Pump air into the engine housing

with the rubber bulb until the

gauge indicates a pressure of

0.5 bar (7.25 psi). If this pressure

remains constant for at least

VA

143RA046

1

20 seconds, the engine or

decompression valve, if fitted, is

airtight.

: However, if the indicated

pressure drops, the leak must be

located and the faulty part

replaced.

To find the leak, coat the suspect

area with oil and pressurize the

engine again. Bubbles will appear if

VA

208RA007

a leak exists.

– If the decompression valve is

leaking, fit a new one – b 6.9.

– Repeat the pressure test.

– Carry out the vacuum test –

b 6.2.3.

– After finishing the test, open the

vent screw and disconnect the

hose.

– Remove the test flange.

– Install the carburetor –

b 11.2.2.

– Remove the flange.

– Remove the sealing plate.

– Install the muffler – b 6.1.

6.2.2 Pressure Test

Loading...

Loading...