26 MS 210, MS 230, MS 250

Oil seals tend to fail when subjected

to a vacuum, i.e. the sealing lip lifts

away from the crankshaft during the

piston's induction stroke because

there is no internal counterpressure.

An additional test can be carried out

with the vacuum pump to detect this

kind of fault.

– Carry out the preparations –

b 6.2.1.

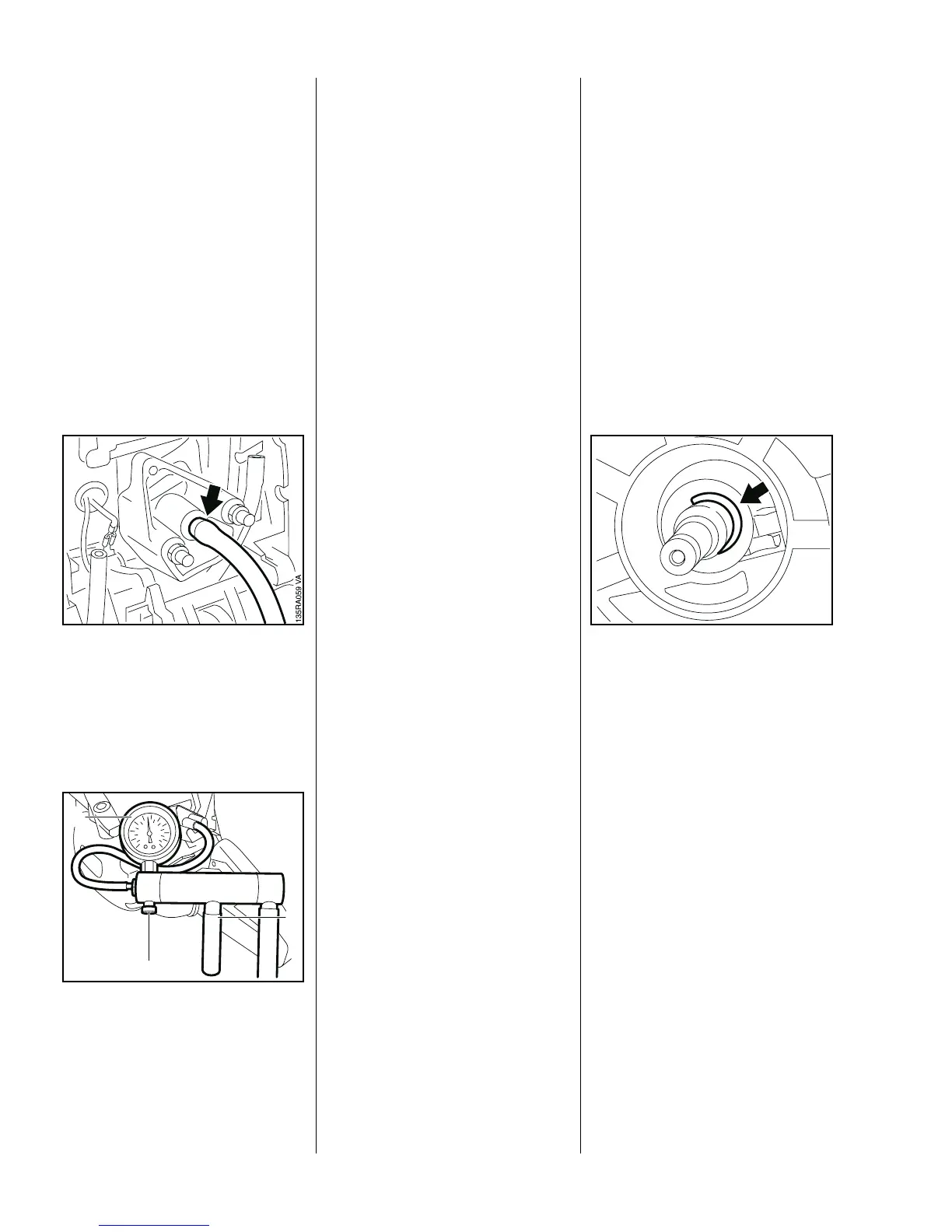

: Connect suction hose of vacuum

pump 0000 850 3501 to test

flange nipple.

: Close the vent screw (1) on the

pump.

: Operate the lever (2) until

pressure gauge (3) indicates a

vacuum of 0.5 bar (7.25 psi).

VA

135RA061

2

1

3

If the vacuum reading remains

constant, or rises to no more than

0.3 bar (4.25 psi) within 20 seconds,

it can be assumed that the oil seals

are in good condition.

However, if the pressure continues

to rise (reduced vacuum in the

engine housing), the oil seals must

be replaced.

– After finishing the test, open the

vent screw and disconnect the

hose.

– Remove the test flange.

– Install the carburetor –

b 11.2.2.

– Remove the flange.

– Remove the sealing plate.

– Install the muffler – b 6.1.

It is not necessary to disassemble

the complete engine housing if only

the oil seals have to be replaced.

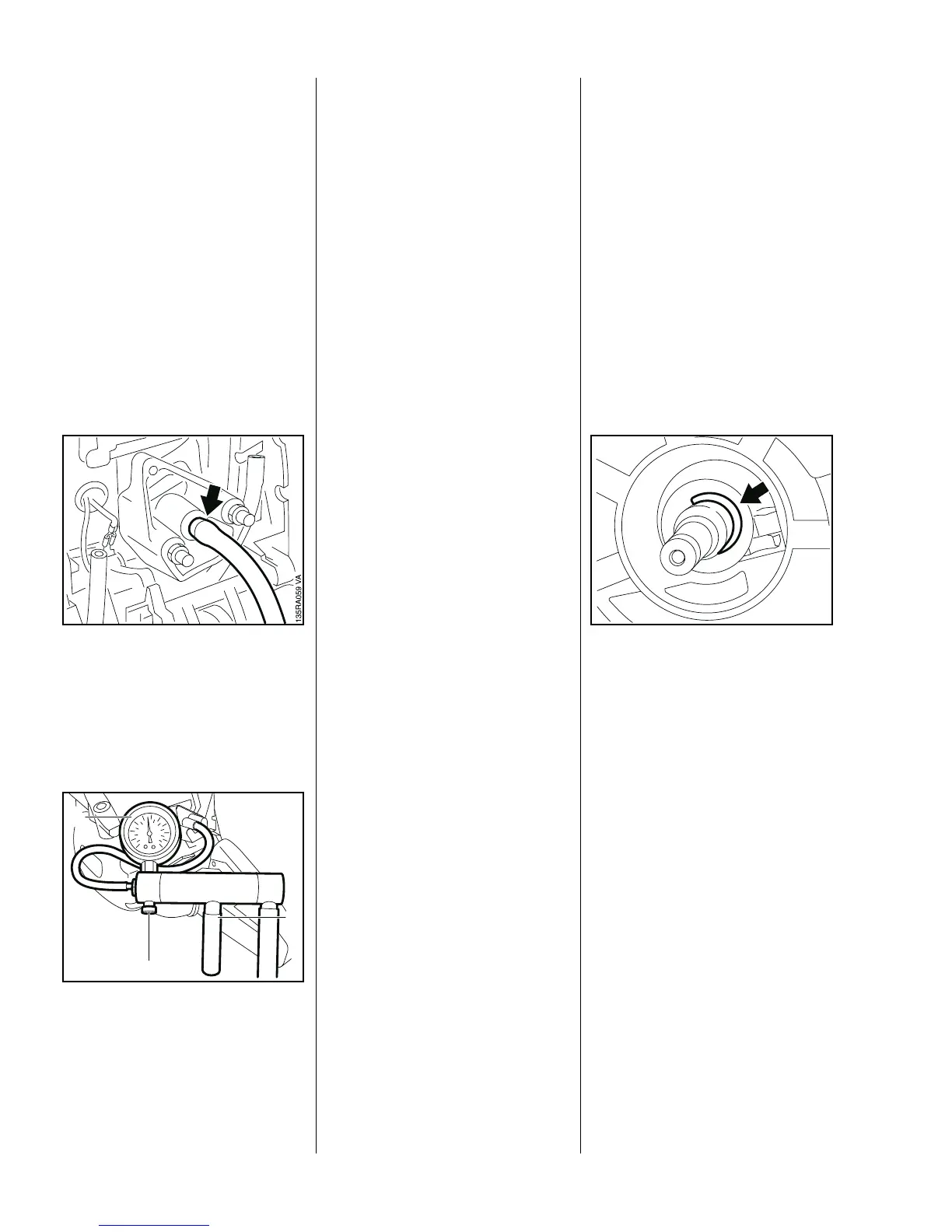

Clutch side:

– Remove the clutch – b 5.3.

– Remove the oil pump – b 10.5.

: Ease the retaining ring out of the

crankshaft.

VA

135RA062

6.2.3 Vacuum Test 6.3 Oil Seals

Loading...

Loading...