NOTICE

If an increased oil flow is no longer required,

reset the adjusting screw to the standard setting.

18 Taking Care of the Guide

Bar

► Turn the guide bar over – every time you

sharpen the chain and every time you replace

the chain – this helps avoid one-sided wear,

especially at the nose and underside of the

bar.

► Regularly clean the oil inlet hole (1), the oil‐

way (2) and the bar groove (3)

► Measure the groove depth – with the scale on

the filing gauge (special accessory) – in the

area used most for cutting

Chain type Chain pitch Minimum

groove

depth

Picco 1/4" P 4.0 mm

Rapid 1/4“ 4.0 mm

Picco 3/8" P 5.0 mm

Rapid 3/8“; 0.325“ 6.0 mm

Rapid 0.404“ 7.0 mm

If groove depth is less than specified:

► Replace the guide bar

The drive link tangs will otherwise scrape along

the bottom of the groove – the cutters and tie

straps will not ride on the bar rails.

19 Cleaning the Air Filter

19.1 If there is a noticeable loss of

engine power

19.1.1 Remove the carburetor box cover.

► Move the Master Control lever (1) to the nor‐

mal run position.

► Loosen the knob (2) in direction of arrow.

► Remove the carburetor box cover (3).

19.1.2 Removing the air filter

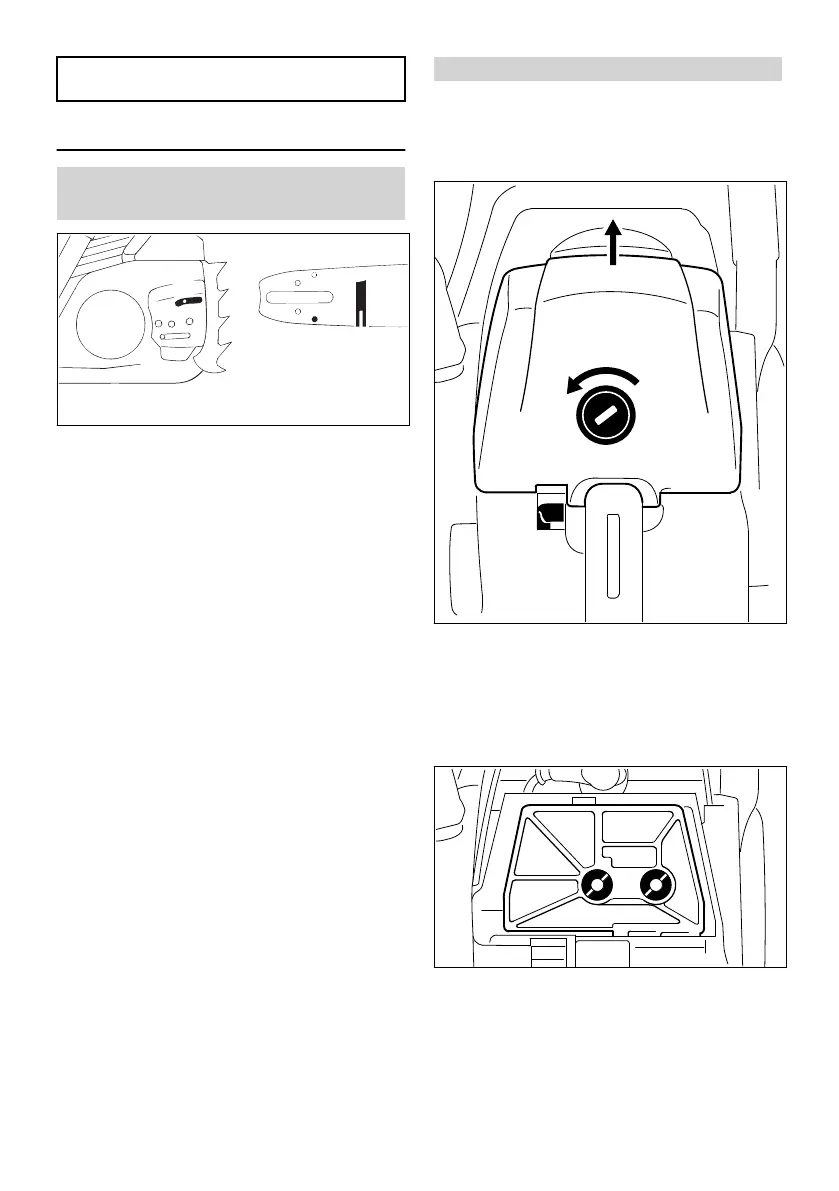

► Clean away loose dirt from around the filter.

► Unscrew the slotted nuts (4).

► Remove the filter (5) and separate the two

halves of the filter.

18 Taking Care of the Guide Bar English

0458-567-0121-B 27

Loading...

Loading...