20

English / USA

TS 400

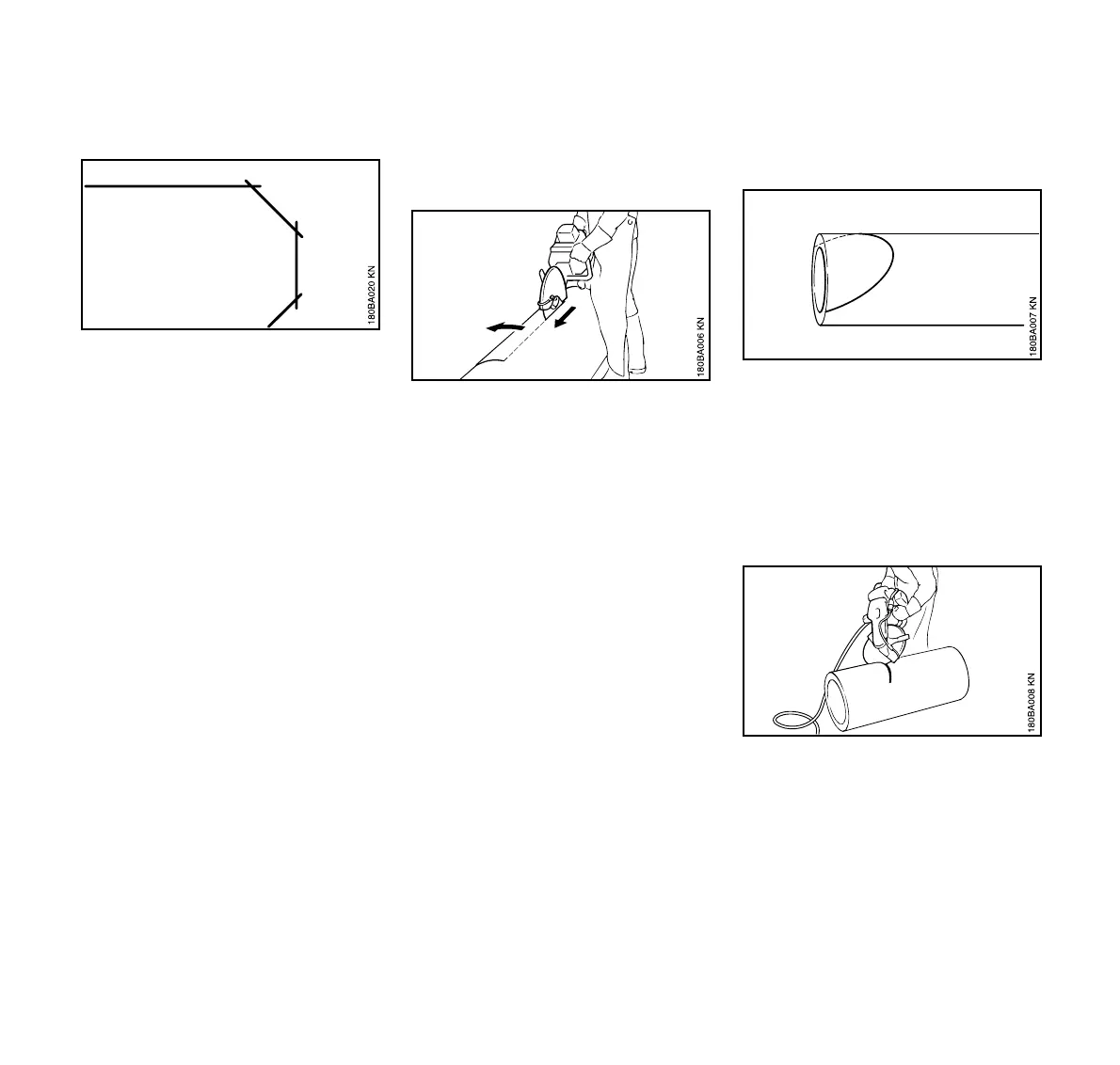

: Curves must be cut in several

straight passes, taking care to

ensure that the cutting wheel does

not become wedged.

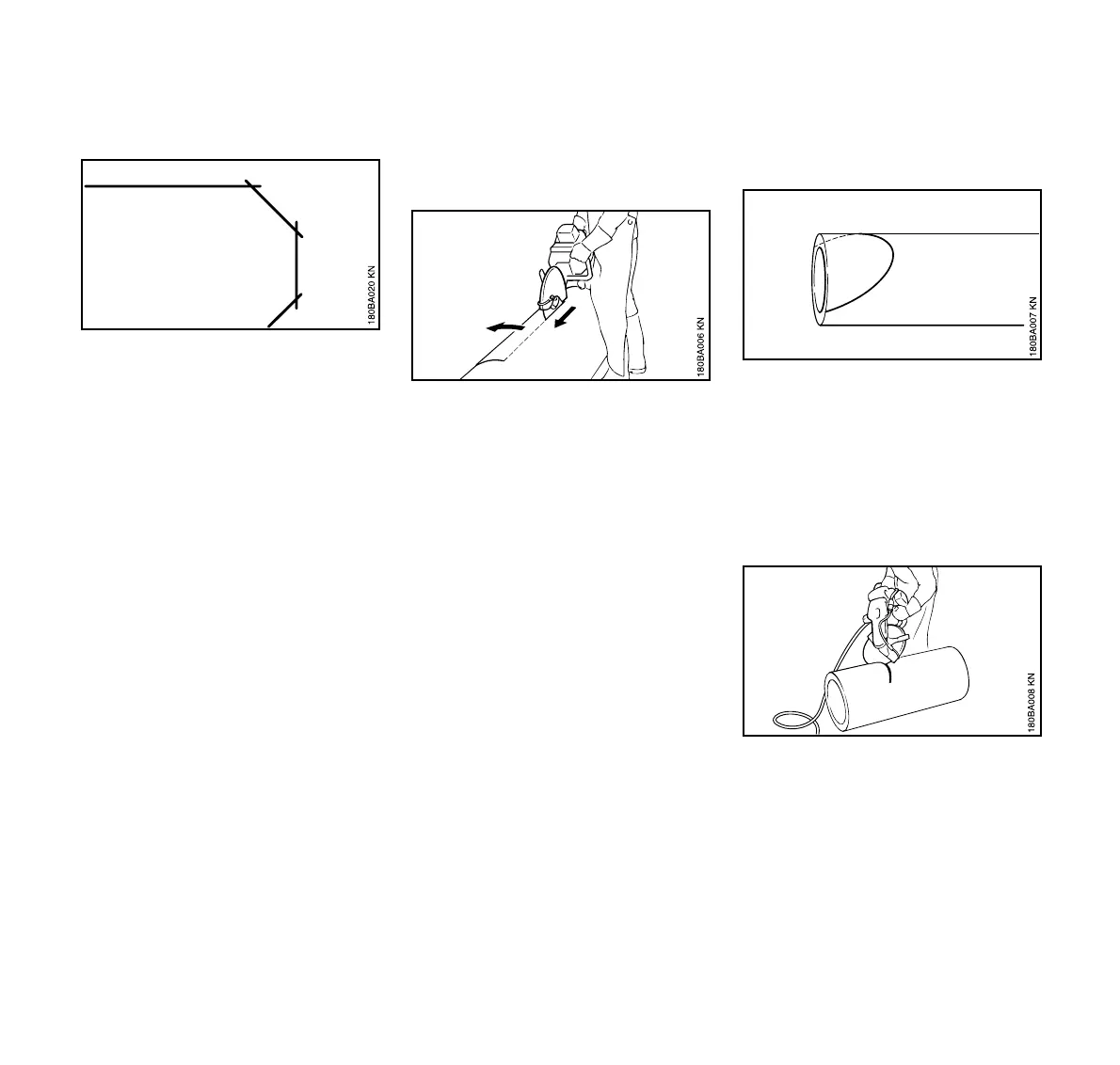

Cutting round and hollow

workpieces

: Pipes and round objects, etc. must

be secured so that they cannot roll.

: Avoid reinforcing elements,

especially in the direction of the cut,

when deciding on the cutting line.

: Cut a guiding groove along the

marked line.

: Cut deeper into the parting cut with

uniform back-and-forth movements.

Advance the cutting wheel along the

guiding groove at full cutting depth.

Always reposition the cutting wheel,

taking care not to wedge it, if the

cutting direction has to be corrected

slightly. If necessary, leave small

ridges of uncut material to hold the

severed part in position. These

ridges can subsequently be broken

through.

Cutting shapes on pipes

: Mark the cutting line.

!Warning!

Particular care and precision are

required for free-hand cutting along such

cutting lines. Avoid side-loading the

wheel or causing it to bind.

: Cut a guiding groove along the

marked cutting line, starting at the

top and moving out towards both

sides.

: Cut into the pipe or round object,

etc. at the ends of the cutting line so

that the material does not chip.

Loading...

Loading...