27TS 400

English / USA

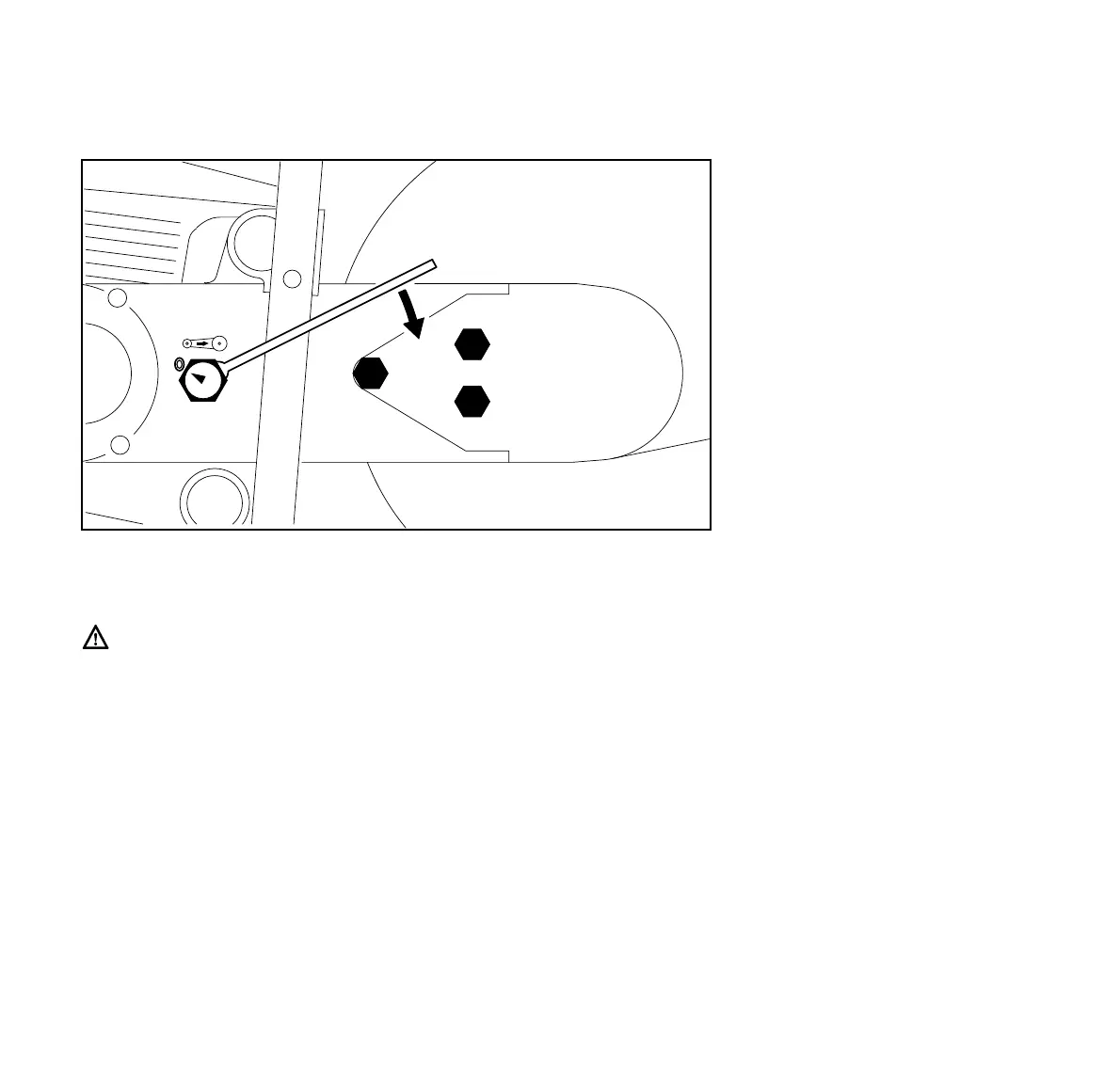

To tension the V-belt:

: Fit the combination wrench over the

tensioning nut as illustrated

The tensioning nut is spring-loaded:

the combination wrench must

therefore be held securely!

: Turn the tensioning nut clockwise.

The spring force begins to act on the

tensioning nut after approx. 1/8 turn

and turns it on as far as the stop

(approx. 1/8 turn)

Do not use force to turn the combination

wrench further!

The V-belt is automatically tensioned

by the force of the spring in this position.

: Remove the combination wrench

from the tensioning nut and

tighten the three hexagon bolts on

the V-belt guard

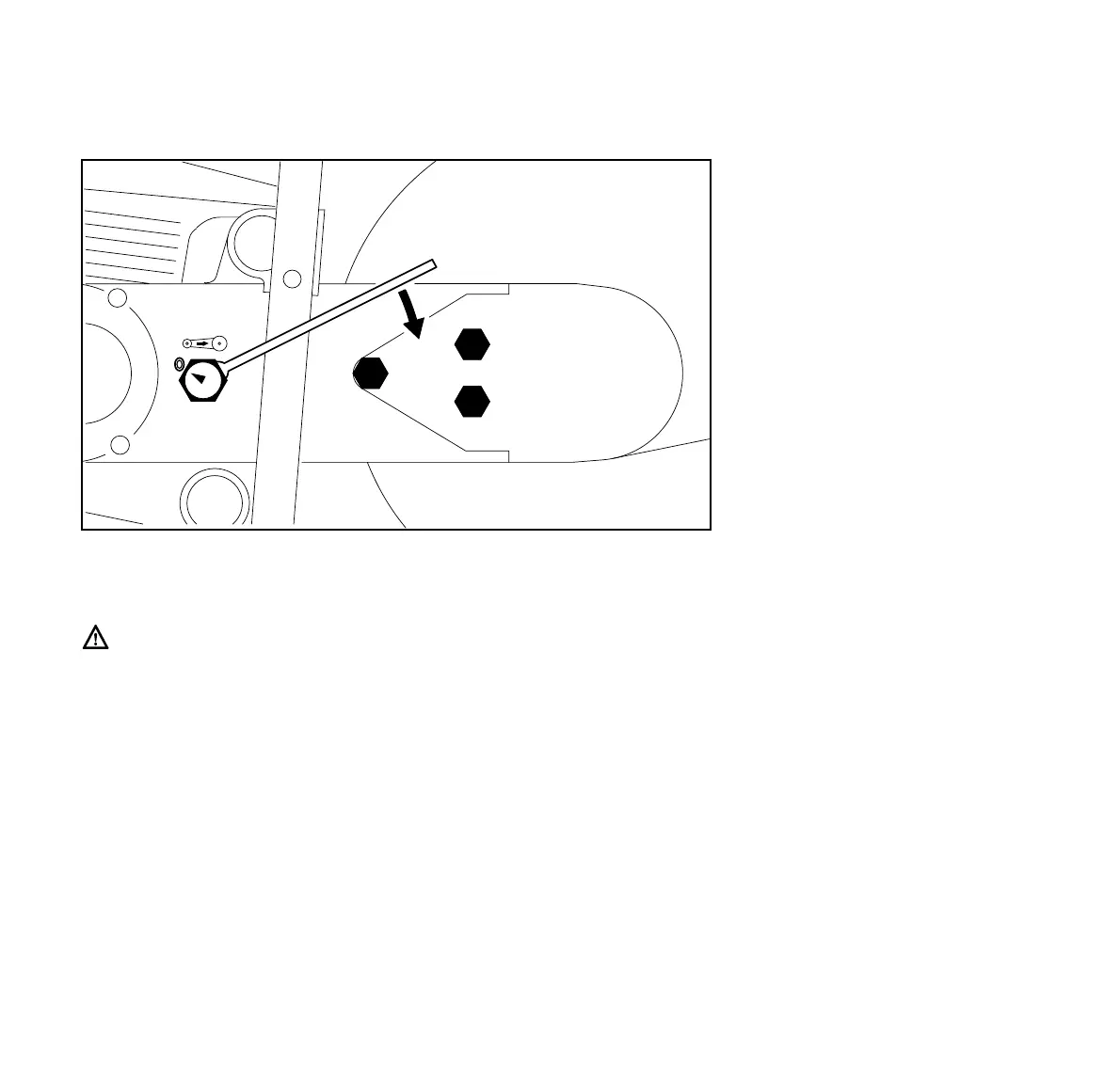

Retensioning

The V-belt is retensioned without

adjusting the tensioning nut

: Unscrew the hexagon bolts (1) on

the V-belt guard

: The V-belt is automatically

tensioned by the force of the spring

: Retighten the hexagon bolts

The abrasive wheels are subjected to

extremely high loads, especially when

cutting free-hand.

The abrasive wheels developed by

STIHL in cooperation with leading wheel

manufacturers are of very high quality

and precisely matched to the application

in question, as well as to the engine

power of the respective cut-off

machines.

They are of consistently outstanding

quality, with high axial and radial runout.

Transport and storage

– The abrasive wheels must not be

exposed to direct sunlight or other

sources of heat during transport and

storage

– Avoid knocks and bumps

– Spare abrasive wheels must be

stored in a dry place at constant

temperature, stacked one on top of

the other on a flat surface, in their

original packaging.

– Diamond abrasive wheels must not

be stored near corrosive liquids

– Composite abrasive wheels must

be protected against frost

338BA005 KN

1

Abrasive wheels

Loading...

Loading...