8

The exchange resin charge is inside the column of the water

softener and takes up a significant part of the total volume

(between 60 and 75%, according to each model). A part of

the column must remain empty, in order to allow for a proper

regeneration of the resin bed.

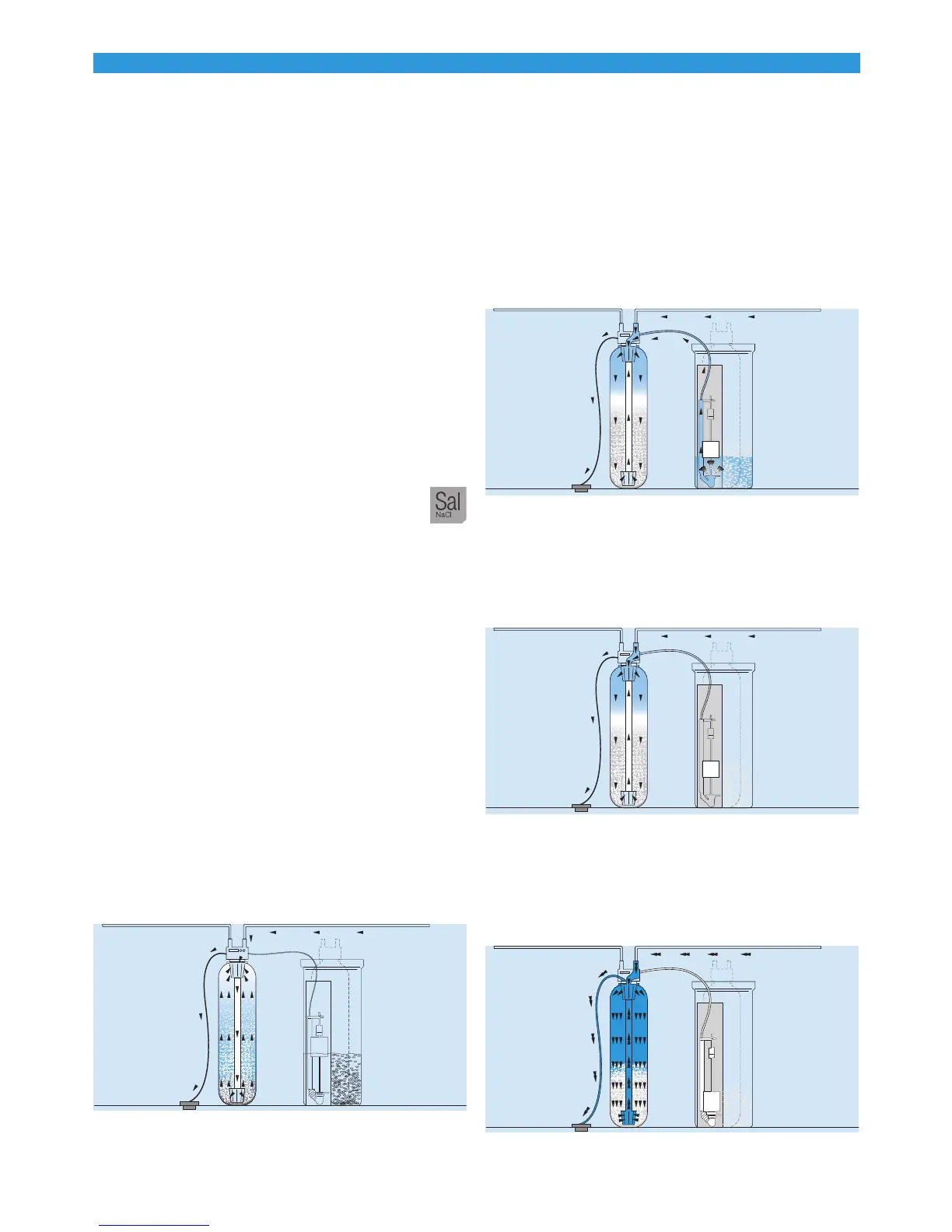

During the treatment process, water goes into the multi-way

valve through the inlet connection, flows towards the upper

part of the tank through the top nozzle and goes downwards

through the bed resin, thus producing the ion exchange.

Treated water is collected by the bottom nozzle and led to

the multi-way valve through the inner tube of the tank. Treated

water is sent for consumption using the outlet connection. At

this point, the system has a treated water meter in order to

measure the water volume.

2.3 Regeneration of the System

The quantity of calcium and magnesium ions that the resin

may retain is limited; therefore, the water volume a water sof-

tener can treat is limited as well.

The system must periodically carry out a process known as

regeneration, which allows the resin to recharge with sodium

ions, so it can continue softening water.

In STRATOS systems, the regeneration process starts auto-

matically when the configured water volume is achieved. The

programmer allows the user to set several regeneration start

modes (see ‘Section 6.3’ to obtain further information how to

operate the programmer).

The regeneration of a softener system is composed of several

stages, which are described below:

BACKWASH:

Water comes into the column through the lower manifold,

washing the suspended mater and fluffing the resin bed up,

thus facilitating the subsequent regeneration process.

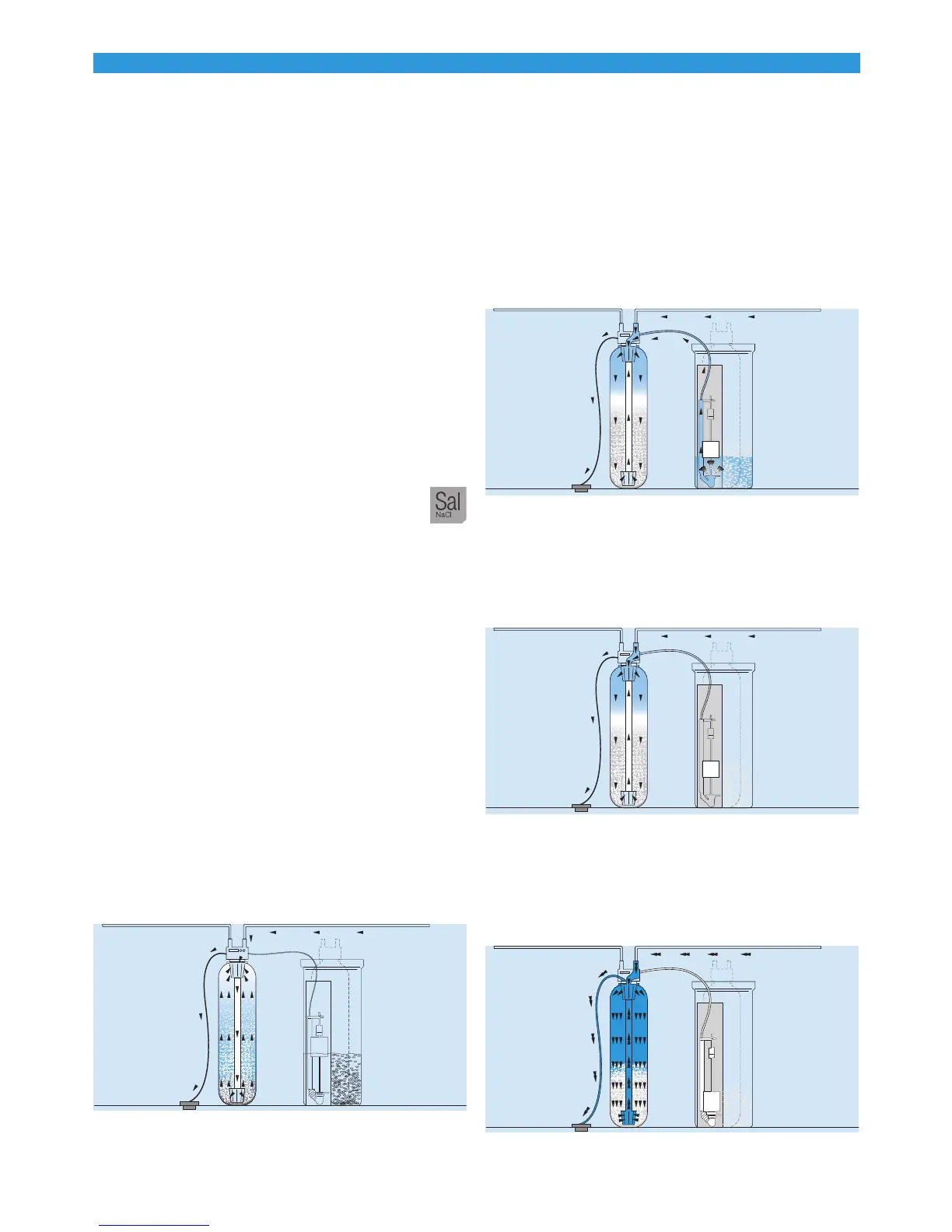

BRINE ASPIRATION:

By means of an aspiration process relying on a Venturi effect,

the system sucks the brine solution, which has previously

been prepared in the regenerating tank. This brine solution is

introduced downwards in the softening column, gets in con-

tact with the ion exchange resin and regenerates it.

SLOW WASH:

In this stage the brine solution, which has been previously

sucked up, goes through the resin bed. Throughout this pro-

cess, the contact between the brine and the resin is complete,

which optimizes the regeneration.

Loading...

Loading...