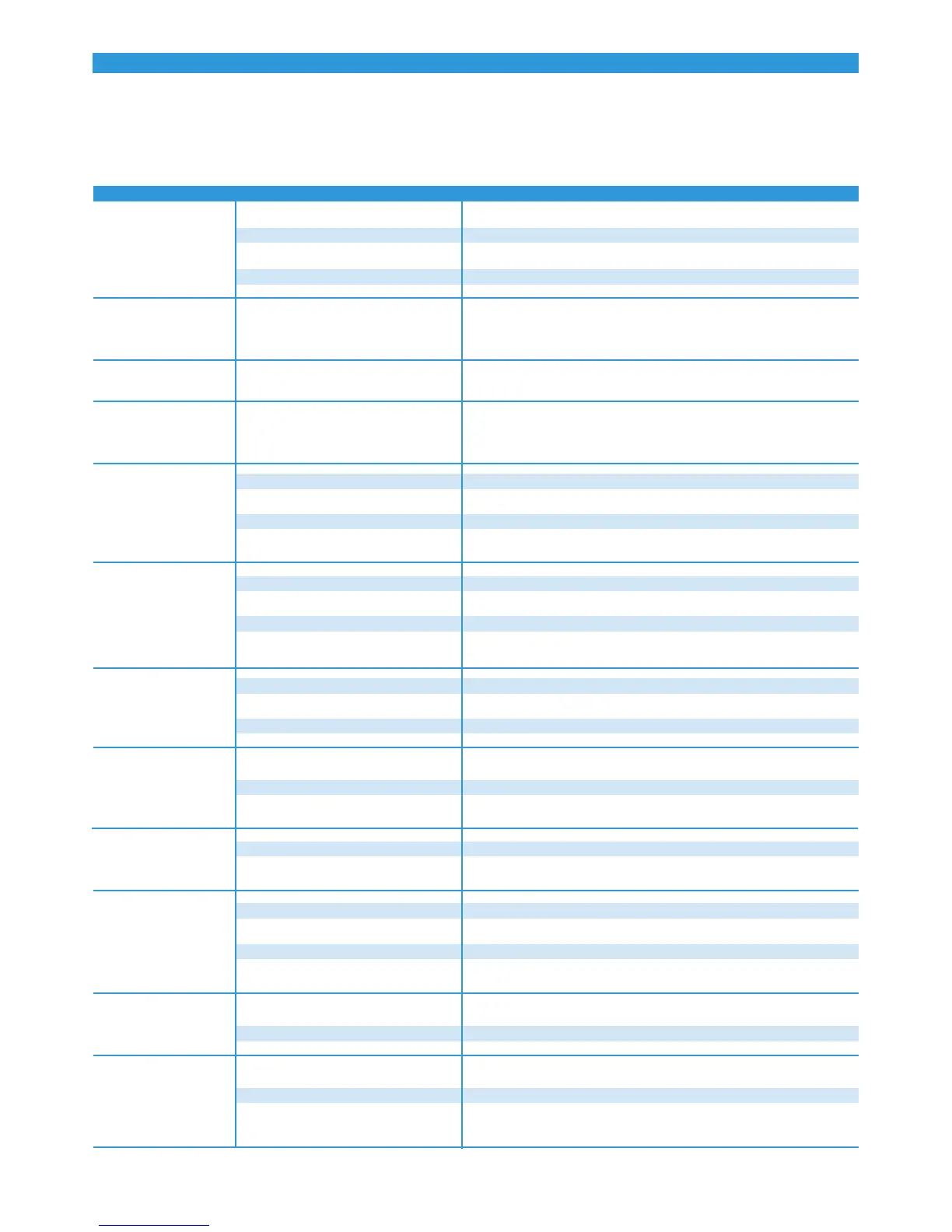

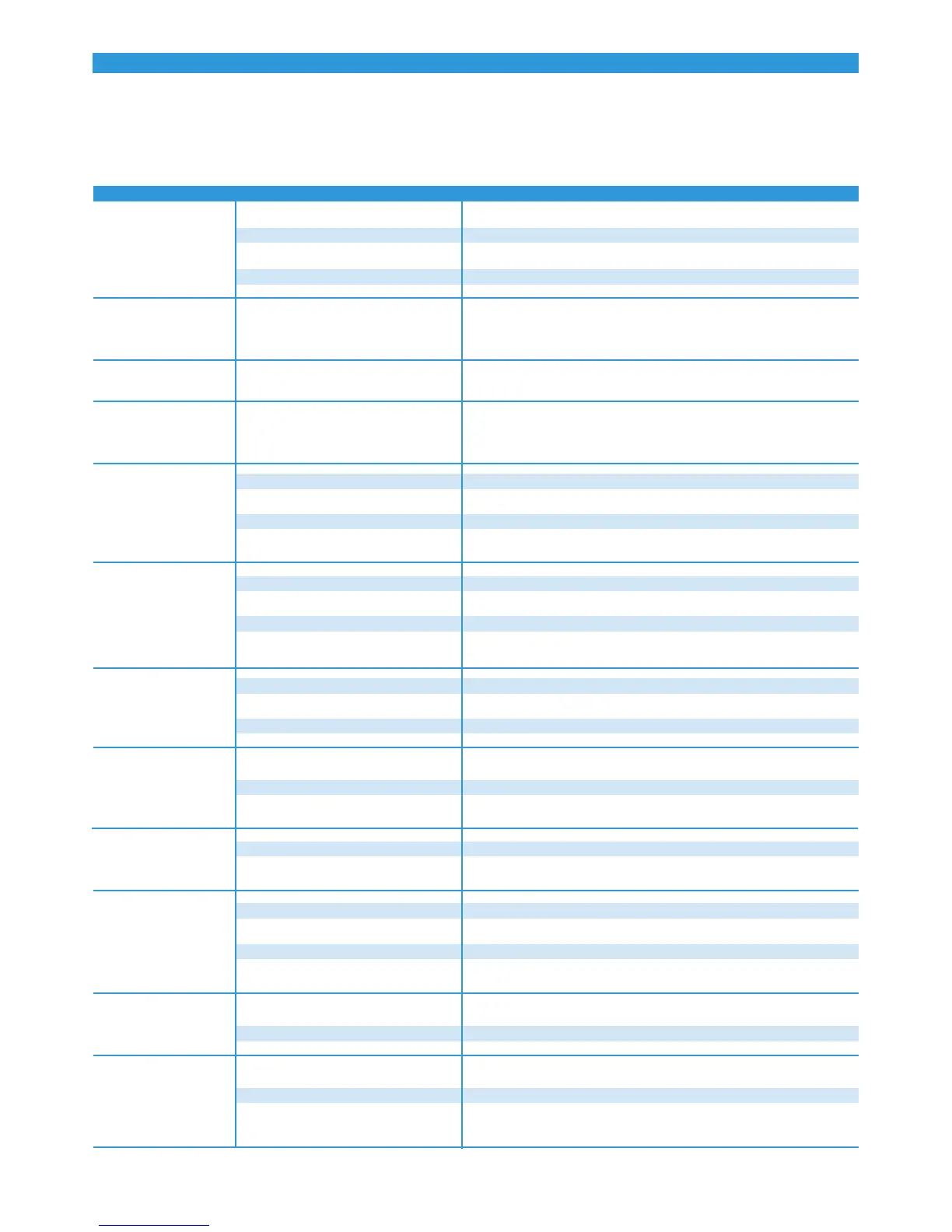

POSIBLE CAUSA

1. The transformer is not plugged.

2. Faulty electrical wire.

3. There is no power supply.

4. Transformer is faulty.

Power interruptions are modifying the sche-

dule.

Connections are loose.

Air inside the system.

1. Hardness in inlet water has increased.

2. Wrong regeneration.

3. Resin is damaged.

4. There is no salt in the tank/salt bridge.

1. Not enough pressure at inlet.

2. Brine line is blocked.

3. Injectors are blocked.

4. Internal water leaks.

1. Forwarding time is not correct.

2. Suction is not correct.

3. Forwarding flow is too high.

1. Failure to start a regeneration.

2. There is not enough brine concentration.

3. Suction is not correct.

1. Backwash regulator is not correct.

2. Backwash regulator is blocked.

1. Wrong regeneration.

2. There are leaks in the by-pass valve.

3. O-ring of the nozzle tube damaged.

4. Regeneration cycle is not correct.

1. Inner diffusers are damaged.

2. Resin is damaged.

1. Joints and separators are damaged.

2. Piston is damaged.

3. Piston is not properly set.

9. GUIDE FOR THE IDENTIFICATION AND SOLUTION OF PROBLEMS

SOLUTION

1. Plug the transformer to a power supply.

2. Replace the wire.

3. Check the installation.

4. Replace the transformer.

Follow the instructions provided in this manual to set the clock.

Tighten the connections.

Carry out an additional backwash to purge the air.

1. Analyse the hardness and program the system again.

2. Check the programming.

3. Replace the resin.

4. Add salt in the system or break the salt bridge.

1. Inlet pressure must be at least 2.5 bars.

2. Clean the brine line.

3. Clean or replace the injector and the filter.

4. Check the piston, joints and separators.

1. Please contact your dealer.

2. Check the suction.

3. Check the forwarding pipes.

1. Check the power supply of the system.

2. Keep the brine tank full of salt.

3. Check the suction.

1. Install an appropriate regulator.

2. Clean the backwash regulator.

1. Carry out a regeneration ensuring that salt is properly adjusted.

2. Check the by-pass valve.

3. Replace the o-ring.

4. Reset the regeneration cycle.

1. Replace inner diffusers.

2. Replace the resin and check the installation.

1. Replace the joints and separators.

2. Replace the piston.

3. Restart the system and repeat the process. If problem persists, please

contact your dealer.

PROBLEM

1. The programmer is not

working

2. The system does not

regenerate when scheduled

3. Water leaks

4. Annoying noises / White

water

5. High level of hardness in

treated water

6. There is no brine suction

7. The brine tank overflows

8. Hardness is not being

removed from water

9. Backwash flow is too

high or too low

10. There are leaks of

untreated water during

service

11. Resin leakage from the

system

12. Water flows through the

drain during service

Loading...

Loading...