Standard user guide

V51-00-V19 eng

-6- Rights to changes reserved

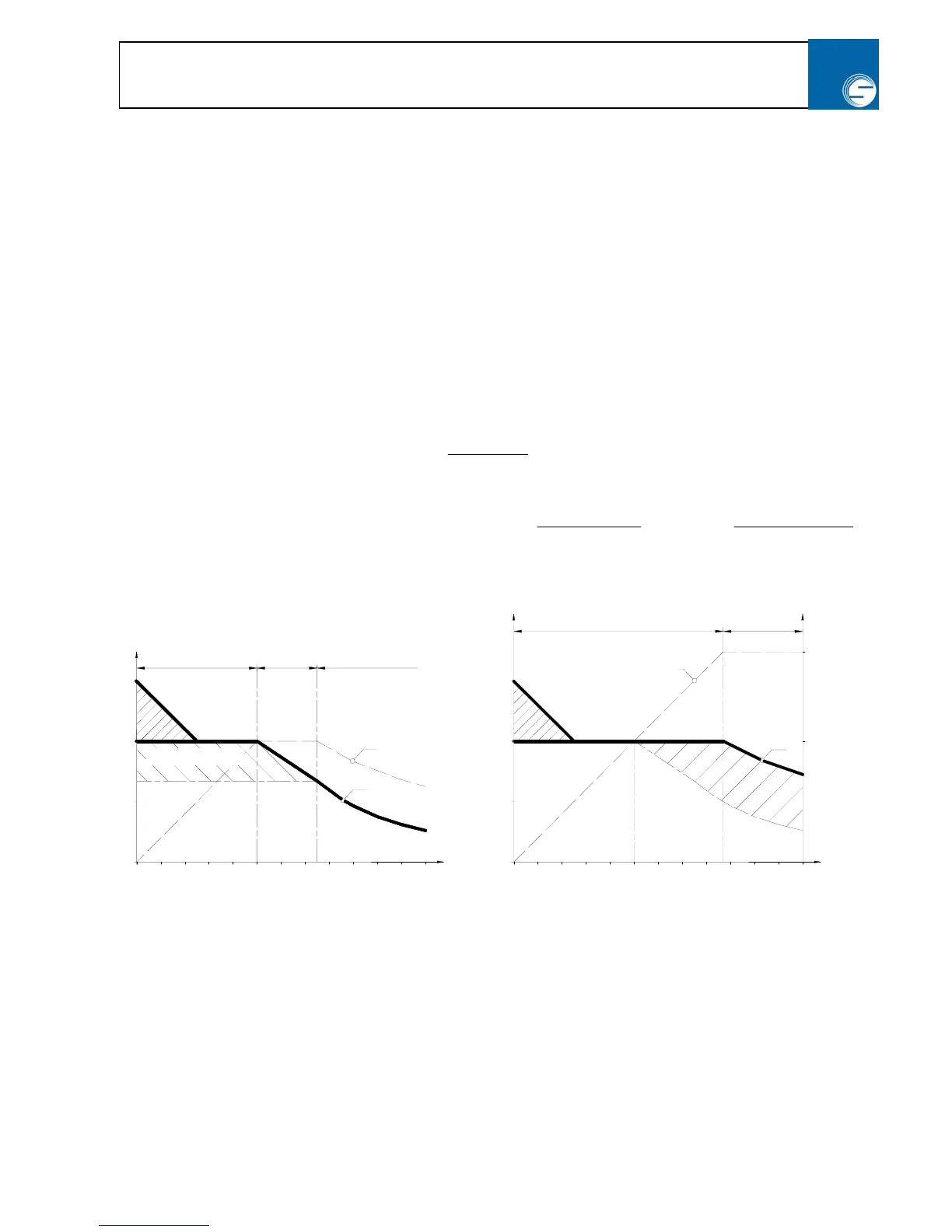

1.5 Power and torque curves

When setting up a drive the torque sequence must be considered in the wanted regulation area.

This can roughly be divided into 3 groups:

• Constantly torque in all regulation area e.g. conveyer

• Rising torque at speed acceleration e.g. Pumps or ventilation.

• Falling torque at speed acceleration e.g. drilling machines or tools machines.

Diagram below might help to choose the right function and power selection.

Power and torque curve

Zone 1: Power rises linear with frequency. Rotation torque M is constant (M

n

).

Warning: By continuous run with motor torque below 20 Hz, use a motor size larger or a motor with

ventilation.

Zone 2:

Power is constant (P

n

)

Torque falls with rising frequency

f

f

M

Knæk

=

n

P5,1

2

2

n

M5,1

f

f

M

Knæk

∗∗

=

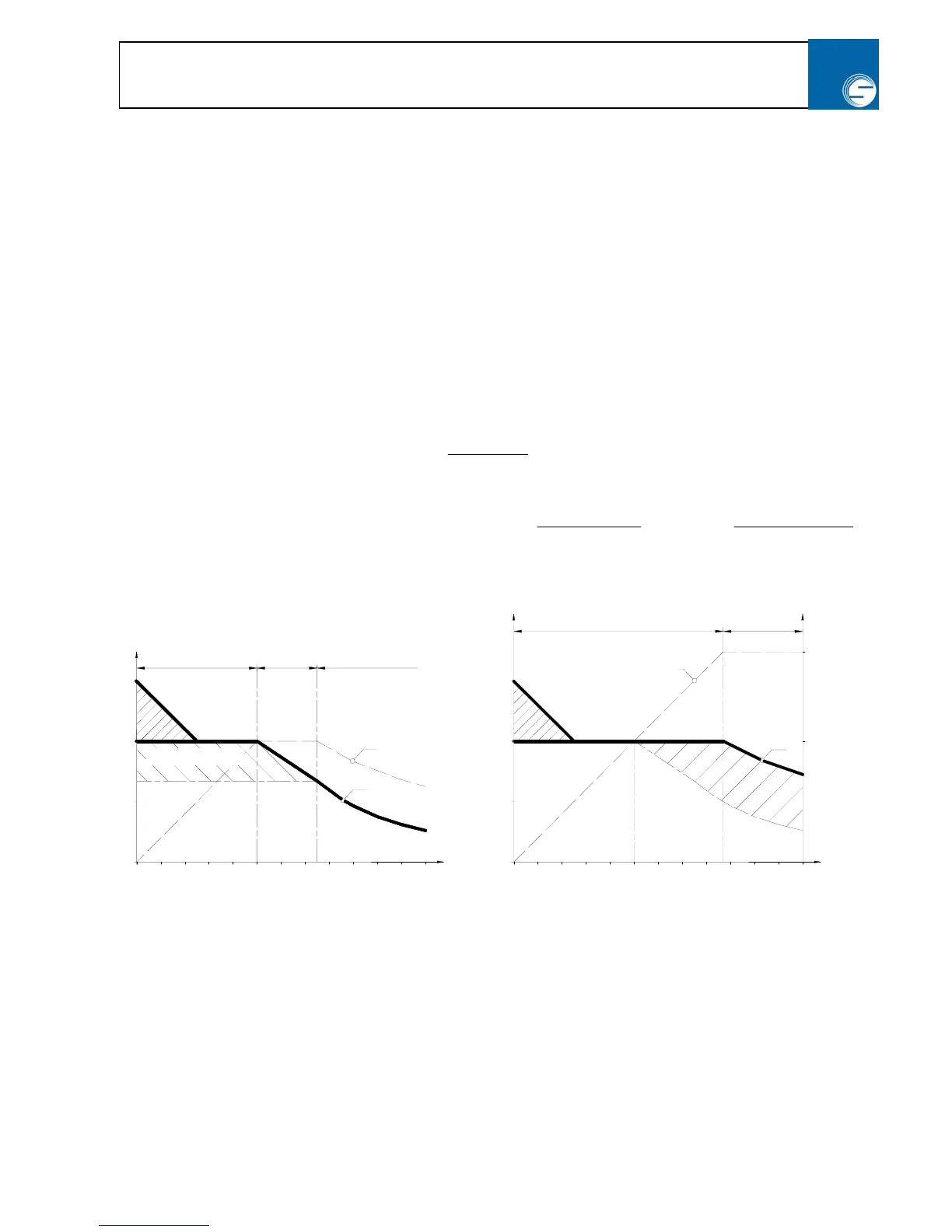

Fig. 1 Fig. 2

Frequency / Voltage point at 50 Hz Frequency / Voltage point at 87 Hz

If you choose to set the systems max frequency to

75 Hz instead of 50. Is it possible to equalize the

smaller motor torque with a larger gearing in the

gear.

Advantages:

• 1,5 times larger regulations area

• 1,5 times larger torque below 50Hz

• Higher start torque.

• Ventilation of motor might not be needed.

Suitable for 3 phased mains supply( SC3- ) and

motor voltages at 230 / 400V by setting the motor in

delta ∆. This way you take advantage of the linear

V/F curve until 87Hz. The motor is supplied with

230V at 50 Hz and 400V at 87Hz

Advantages:

• 1,73 times larger regulations area

• 1,73 times larger motor power at 1,73 times

larger frequency inverter power.

• 100% torque from above 87 Hz.

[Hz]

50

20

10

30

40

50

60

100

70

80

90 110 120

150

[%]

P/M

P

M

50

20

10

30

50

40

60 80

70

90

[Hz]

110100 120

P/M

100

150

[%]

P

M

230

400

[V]

100

Zone 1 Zone 2 Zone 3

Zone 1 Zone 2

Motor-

voltage

Frekvens

knækpunkt

Moment overskud f < 75Hz

Kun under start

(Boost)

Kun under start

(Boost)

Frekvens knækpunkt 87 Hz

Moment forhøjelse i

forhold til Fig. 1

Moment forhøjelse i

forhold til Fig. 1

Loading...

Loading...