Sealed System Information

600 Series

(Prior to #1810000)

4-4

#3756270 - Revision B - January, 2006

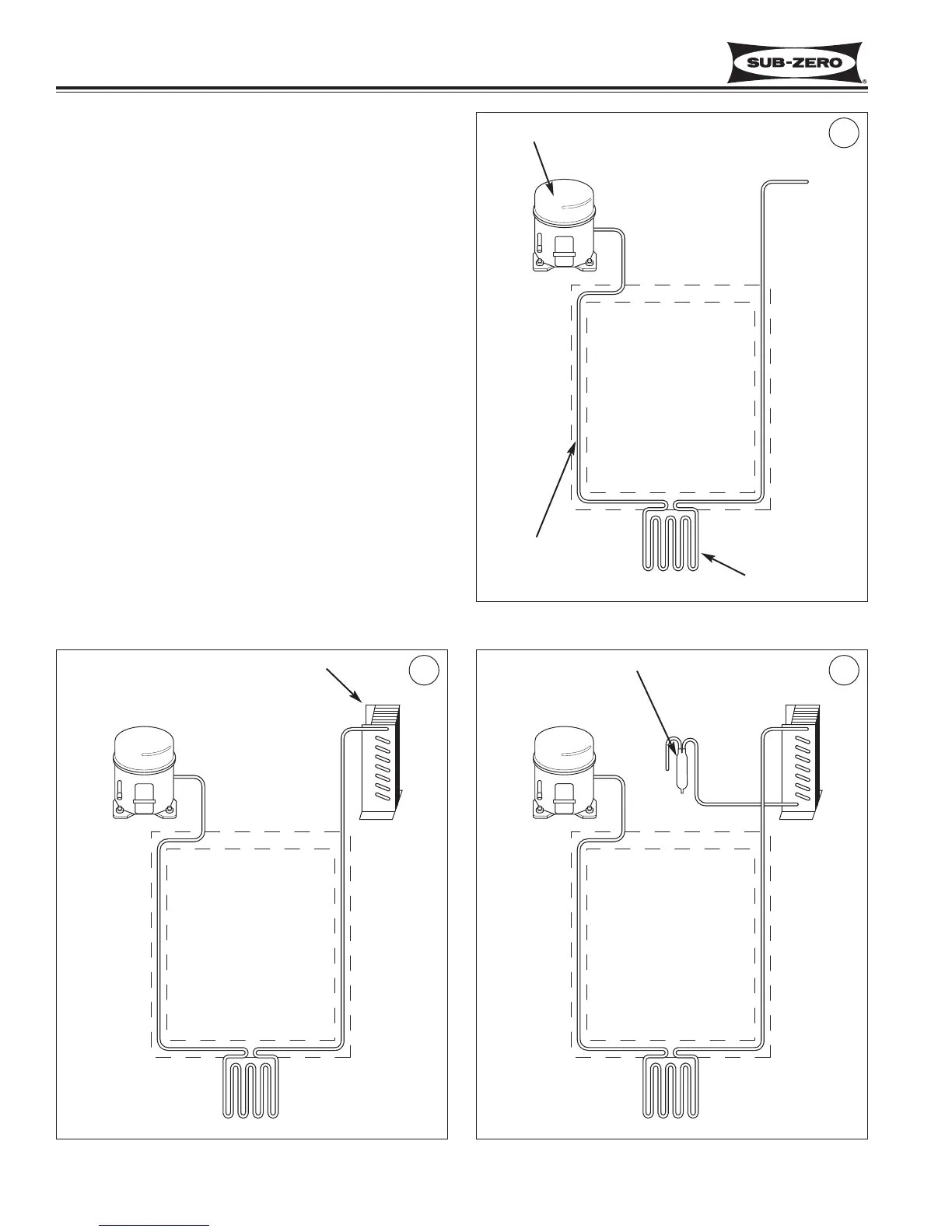

Figure 4-1. Compressor

1

3

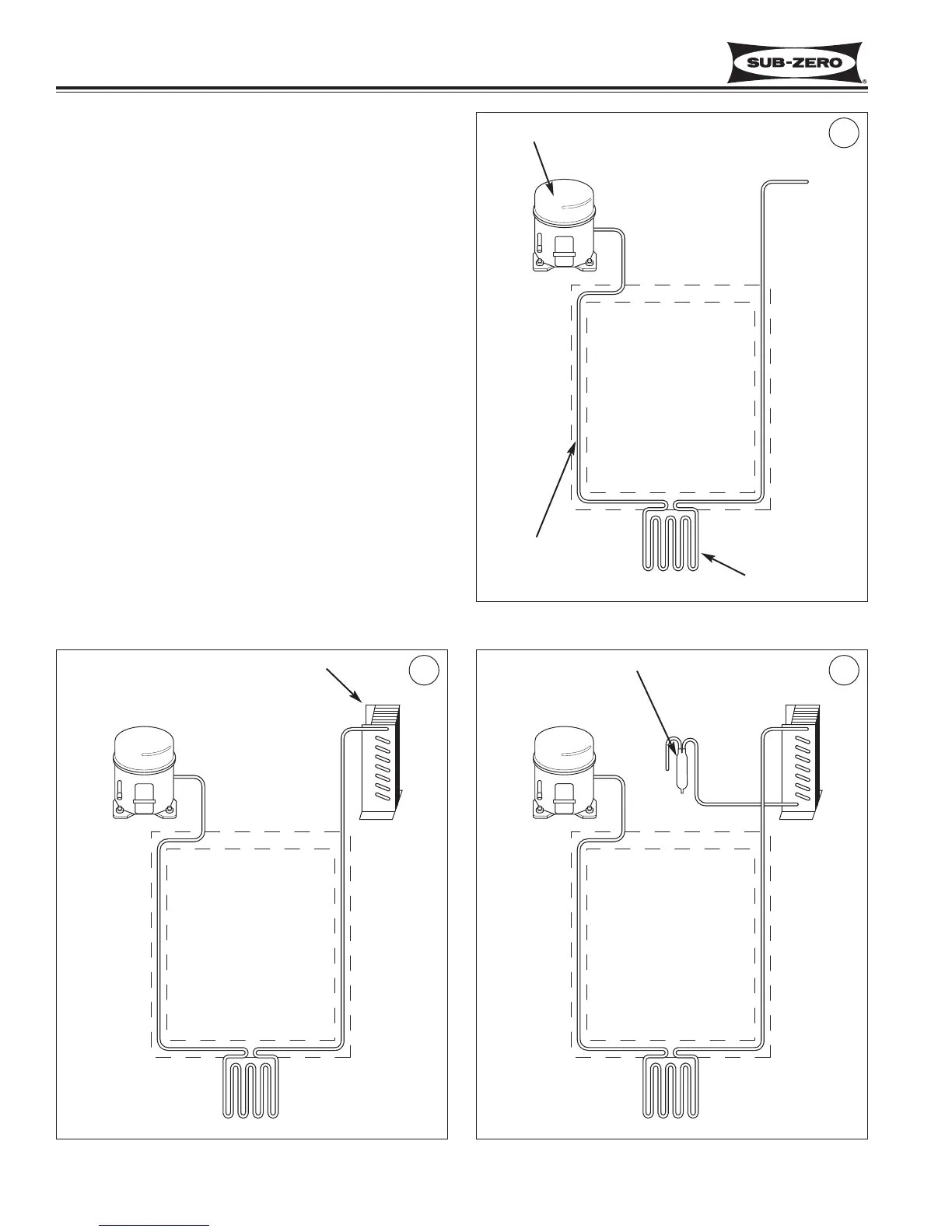

Figure 4-2. Condenser

2

SEALED SYSTEM OPERATION

The following six diagrams illustrate a basic sealed sys-

tem. The components are listed in order of refrigerant

flow, with an explanation of their fundamental role as part

of a sealed system. NOTE: These illustrations do not

represent any specific 600 Series sealed system.

Compressor (Figure 4-1)

The compressor creates a high side and low side pres-

sure difference in the sealed system by compressing the

refrigerant gas, thus raising the pressure and tempera-

ture. The compressor pushes this high-pressure/high-

heat gas through the door gasket seat heater loop to pre-

vent sweating (on most units the gas also travels through

drain pan heater tubing to help evaporate water in the

drain pan). The high-pressure/high-heat gas then travels

to the condenser.

Condenser (Figure 4-2)

The high-pressure/high-heat gas travels through the con-

denser, where the heat is dissipated by cooler air being

drawn over the condenser tubing by the condenser fan.

This changes the gas into a high-pressure/warm liquid

that then enters the high-side filter-drier.

High-Side Filter-Drier (Figure 4-3)

The high-pressure/warm liquid travels through the high-

side filter-drier, which removes moisture from the refriger-

ant before it enters the capillary tube.

Compressor

Drain Pan

Heater Tubing

Door Gasket

Seat Heater

Loop

Condenser

High-Side Filter-Drier

Figure 4-3. High-Side Filter-Drier

Loading...

Loading...