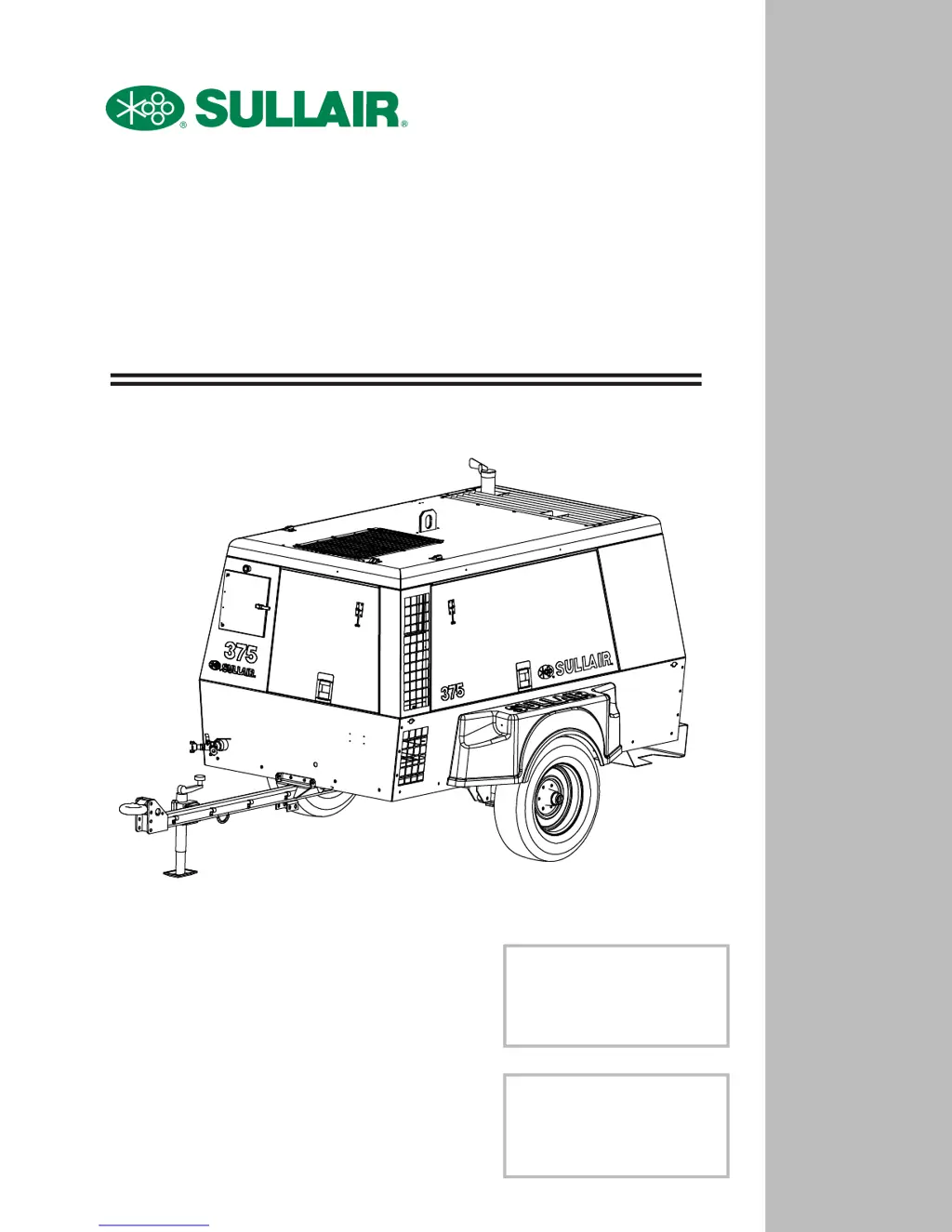

Why is my Sullair Air Compressor not achieving full discharge pressure?

- LLaura PearsonAug 19, 2025

If your Sullair air compressor isn't reaching full discharge pressure, it could be due to: * The run/start valve not being in the run position (for compressors with idle warm-up controls, switch the valve to RUN). * Excessive air demand (check service lines for leaks or open valves). * A dirty air filter (check the filter and change the element if required). * A defective pressure regulator (check the diaphragm and replace with a kit if necessary). * A defective idle warm-up control (replace the control).