What to do if the Sullair 425H Air Compressor shows a low fuel level?

- RRobert McgeeSep 12, 2025

If the Sullair Air Compressor indicates a low fuel level, check the fuel level and fill the tank if it is empty.

What to do if the Sullair 425H Air Compressor shows a low fuel level?

If the Sullair Air Compressor indicates a low fuel level, check the fuel level and fill the tank if it is empty.

Why does my Sullair Air Compressor engine crank but not start?

There are several potential reasons why your Sullair Air Compressor engine cranks but doesn't start: * **Low voltage or battery issues:** Check and tighten battery cables and the ground wire. Recharge or replace the battery if needed. * **Blown fuse:** Inspect and replace any blown fuses in the wiring harness. * **Loose instrument panel connectors:** Check and reattach any loose connectors. Also, inspect wires for breaks or corrosion, cleaning or replacing them as necessary. * **Faulty SSAM module:** Consider replacing the SSAM module.

How to fix Sullair Air Compressor that does not crank?

If your Sullair Air Compressor doesn't crank, it might be due to low voltage or a disconnected battery. Check the battery cables and tighten them if they are loose. Also, check the ground wire for proper attachment to the frame and tighten if required. If the battery is the issue, recharge or replace it. Another potential cause is a blown fuse in the wiring harness, so remove and inspect the fuse, replacing it if necessary.

| Model | 425H |

|---|---|

| Type | Portable Rotary Screw Air Compressor |

| Maximum Pressure | 150 psi |

| Flow Rate | 425 cfm |

| Air Delivery | 425 cfm |

| Noise Level | 76 dBA |

| Drive Type | Direct Drive |

| Engine | John Deere 4045 |

| Fuel Tank Capacity | 58 gallons |

General safety responsibilities and precautions for compressor operation.

Safety procedures for preparing to tow and actual towing of the compressor.

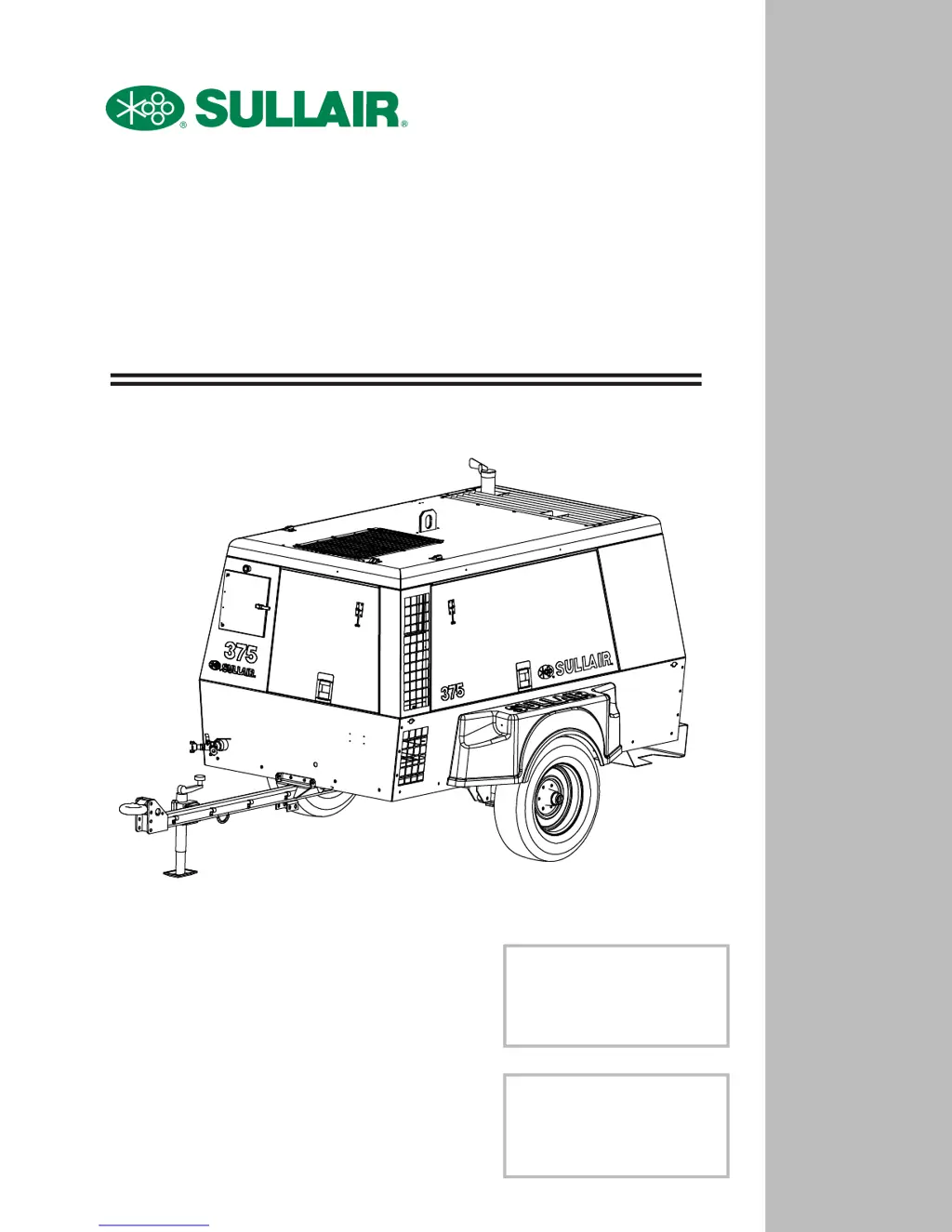

Identification of main components and subassemblies of the air compressor package.

Technical specifications for 300HH, 375, and 375H models.

Technical specifications for 375HH, 425, and 425H models.

Explanation of the purpose and location of various compressor controls and indicators.

Recommended daily maintenance checks and procedures for the compressor.

Legal prohibition against tampering with the compressor's noise control systems.

Illustrated parts breakdown for the engine, compressor, and associated components.

Illustrated parts for the radiator and compressor fluid cooling system.

Illustrated parts breakdown for the compressor's electrical system components.

Illustrated parts breakdown for the instrument panel and its associated components.

Loading...

Loading...