E900H User Manual 6: Maintenance

02250203-986 R03

Subject to EAR, ECCN EAR99 and related export control restrictions. 45

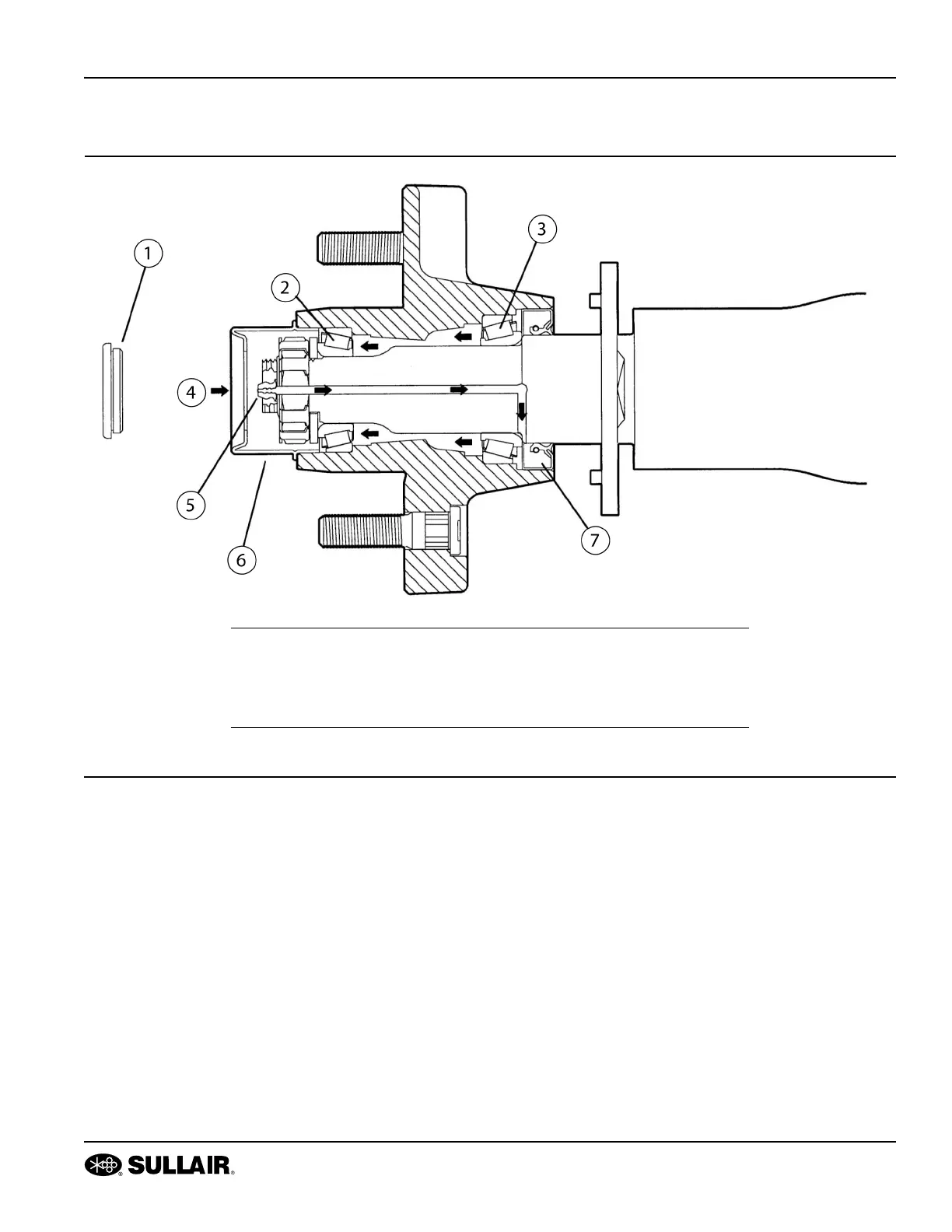

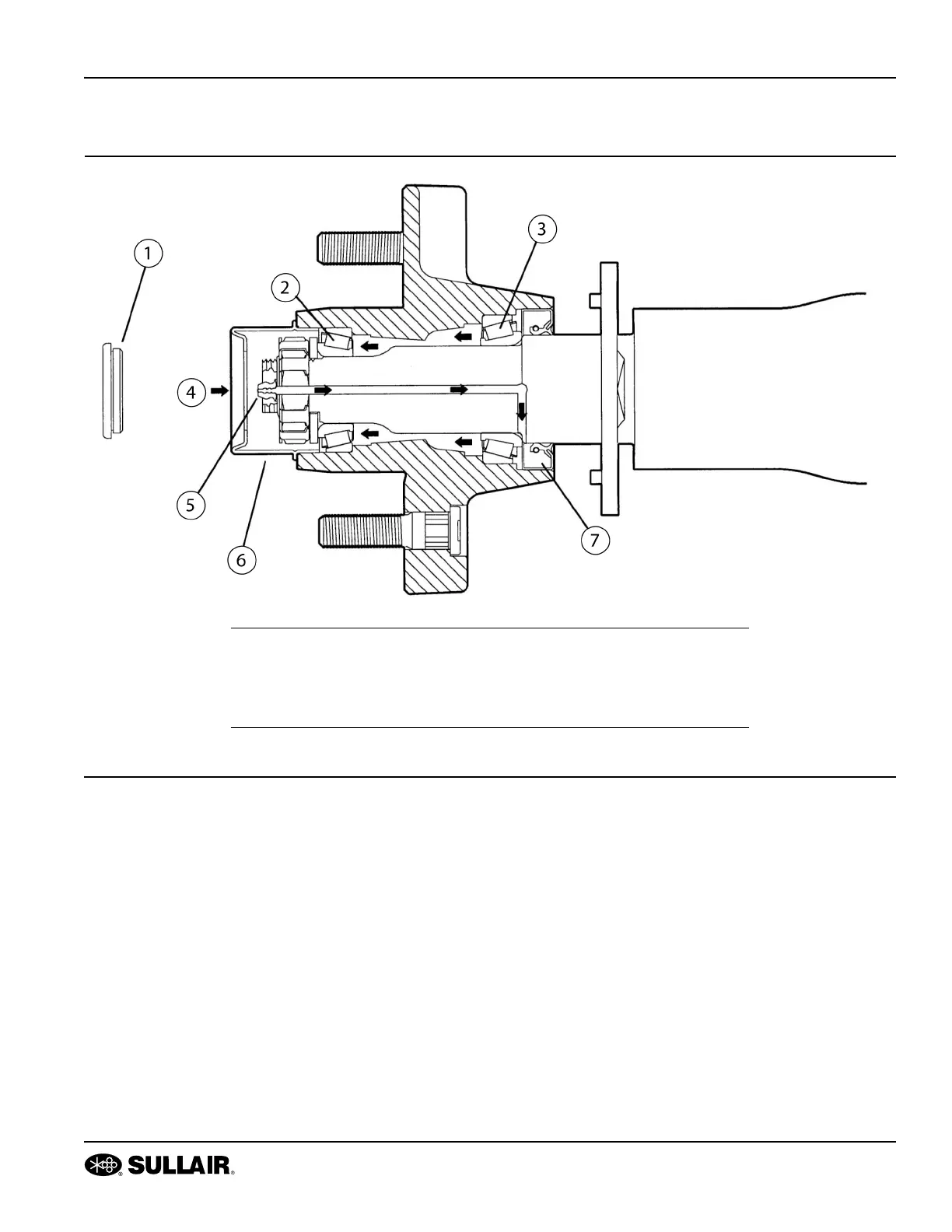

6.9.3 Wheel bearing lubrication

Refer to Figure 6-2. Proper lubrication is essential to the

proper functioning and reliability

of your portable com-

pressor axle. Wheel bearings should be lubricated at

le

ast once every 12 months, or more frequently to help

insure proper performance. Use wheel bearing grease

that conforms to military specification MIL-G-10924 or a

high temperature wheel bearing grease such as lithium

complex NLGI Consistency #2.

If your axle is equipped with the E-Z Lube feature, the

b

earings can be periodically lubricated without removing

the hubs from the axle. This feature consists of axle spin-

dles that have been specially

drilled and fitted with a

grease zerk in their ends. When grease is pumped into

the zerk, it is channeled to the inner bearing and then

flows back to the outer bearing and eventually back out

of the grease cap hole (refer to Figure 6-2). The proce-

dure is as follows:

1. Remove the rubber plug from the end of the

grease cap.

2. With a standard grease gun filled with a qual-

ity wheel bearing grease, place the gun onto

the grease zerk located in the end of the

spindle. Make sure the grease gun nozzle is

fully engaged on the fitting.

3. Pump grease into the zerk. The old, dis-

placed grease will flow back out of the cap

around the grease gun nozzle.

4. When new, clean grease is observed,

remove the grease gun, wipe off any excess,

and replace the rubber plug in the cap.

Figure 6-2: Typical E-Z Lube axle

1. Rubber plug 5. Grease fitting

2. Outer bearing 6. Metal end cap

3. Inner bearing 7. Spring-loaded double lip seal

4. Grease flow

Loading...

Loading...