Section 4

INSTALLATION

30

the sump is properly filled, the fluid level should be

visible in the sight glass.

4.6 MOTOR ROTATION DIRECTION CHECK

Pull out the EMERGENCY STOP button and press

once, quickly and in succession, the (START)

and (STOP) pads. This action will bump start

the motor for a very short time. Verify proper rota-

tion by observing the motor shaft during start-up.

The shaft should rotate in the same direction as

indicated by the rotation decal located on the motor

adapter. If the motor shaft is not turning in the prop-

er direction, disconnect power to the compressor

and exchange any two of the three power-input

leads, then recheck rotation.

An alternative to this procedure is to set the

Supervisor to display P1. Pull out the EMER-

GENCY STOP button and press once, quickly and

in succession, the (START) and (STOP)

pads. This action will bump start the motor for a

very short time. If motor rotation is correct there will

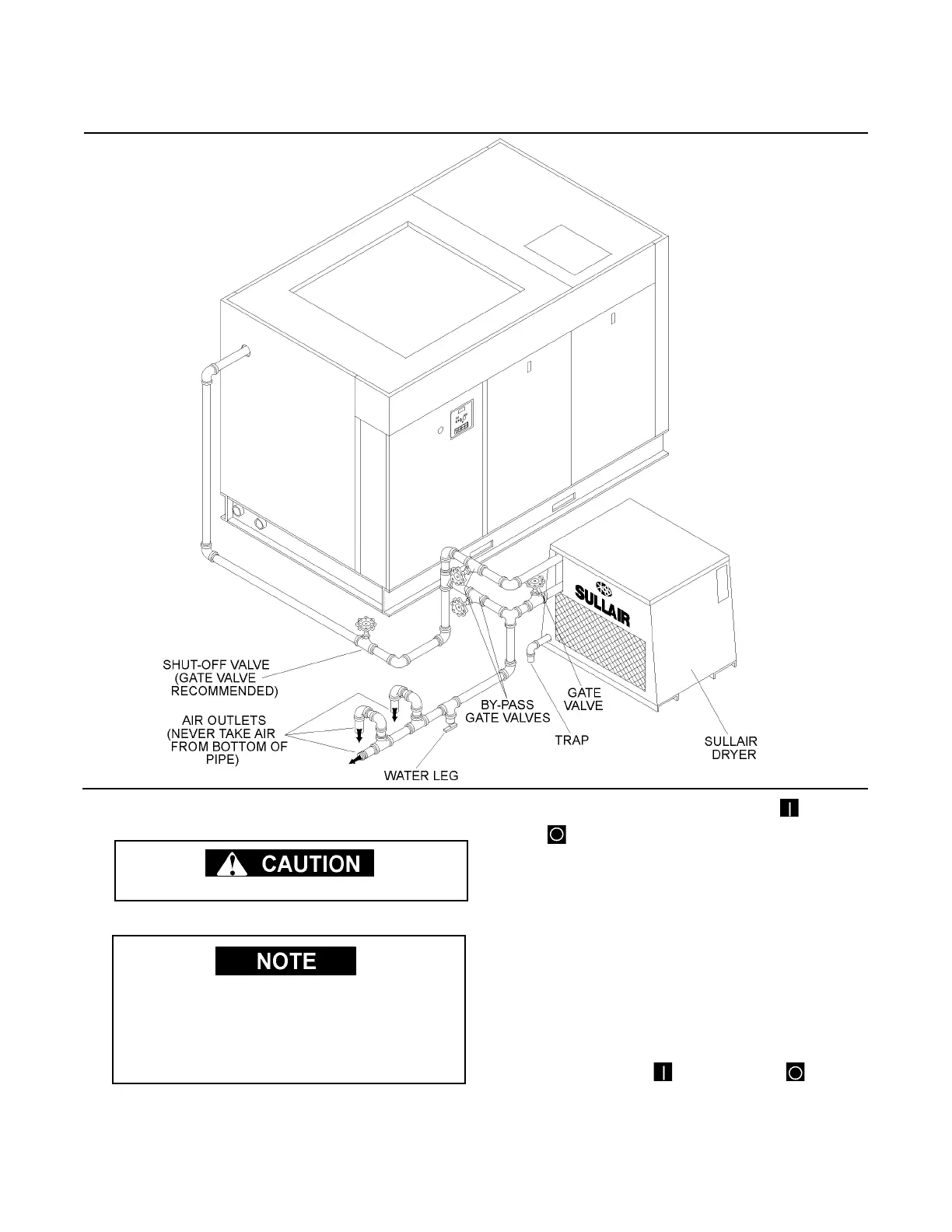

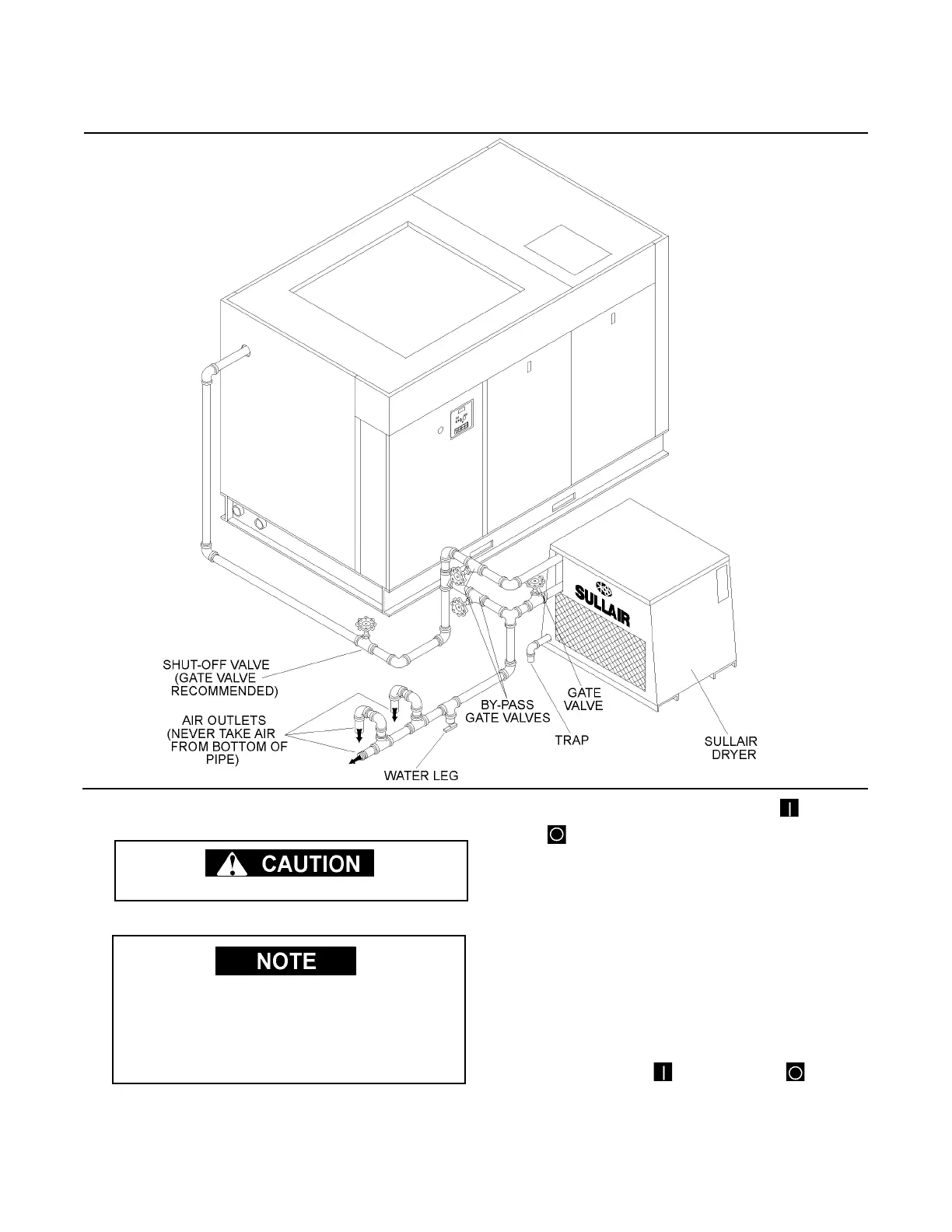

Figure 4-1 Service Air Piping (Typical Installation)

Motor rotation check must be made at compres-

sor start-up. Remove compressor panel as need-

ed to view motor rotation.

After the electrical wiring has been done, it is

necessary to check the direction of the motor

rotation.

Do not overfill.

Loading...

Loading...