SRL Service Manual

Revision 00

July 2007

Page 16 of 56

3.1.5 Dew Point Temperature Sensor

All models have a Dew Point Temperature Sensor that measures the temperature of the air leaving

the Air-to-Refrigerant Heat Exchanger. At this point in the dryer, the temperature of the air is

theoretically equivalent to what the outlet dew point will be. This is the dew point temperature which is

shown on the digital display during normal operation.

3.1.6 Condensate Level Sensor

All models except the SRL-250* have a Level Sensor in the Condensate Chamber. This sensor sends

a signal to the microprocessor when the level of condensate reaches it, which then opens the

Condensate Drain Valve. Details of condensate drain operation are covered in Section 9.

* There is not enough volume in the condensate chamber of the SRL-250 to allow efficient zero air loss drain

operation, so no level sensor is required.

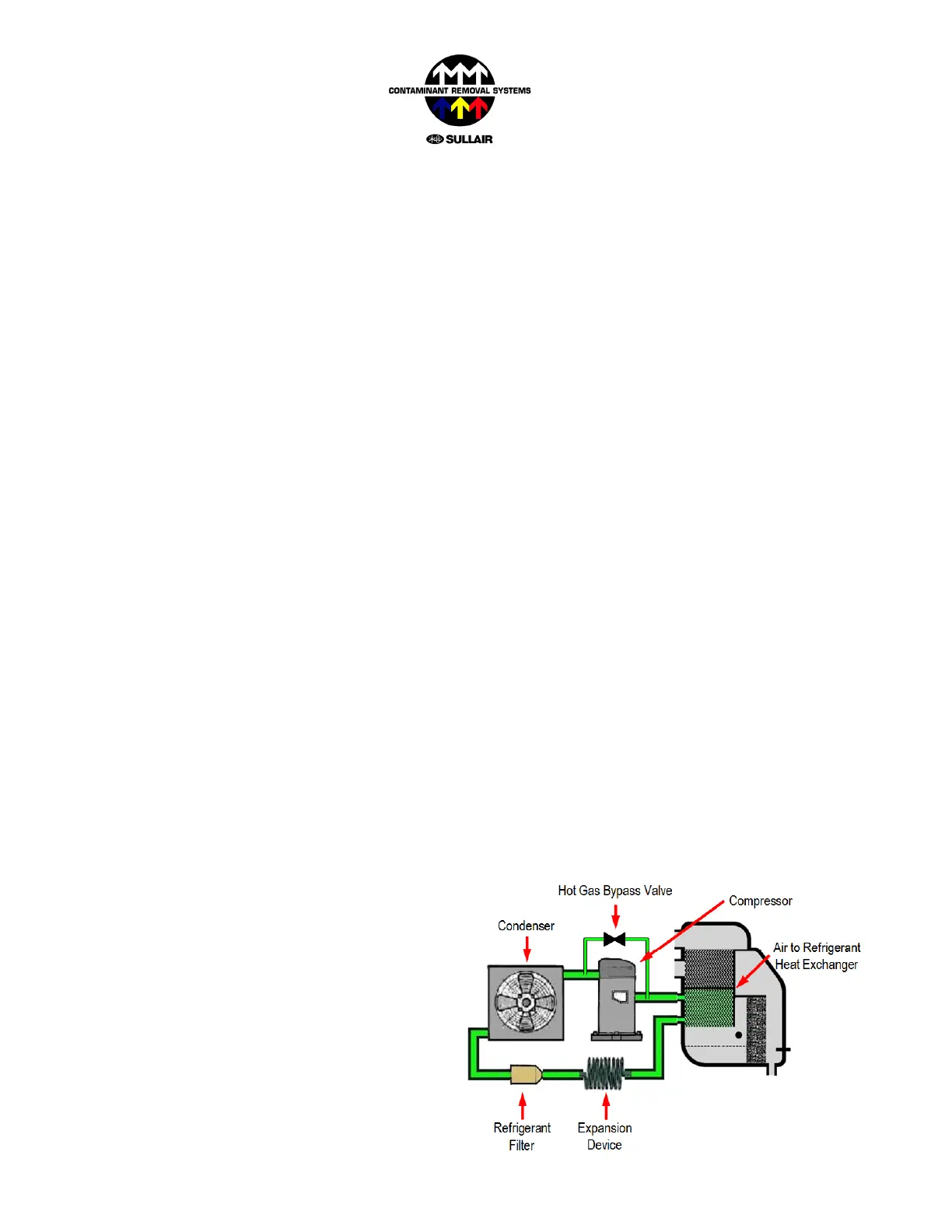

3.2 Refrigeration Circuit

All models have the option of operating in continuous mode, or operating in cycling mode on a thermal

mass principal. For an overview of the thermal mass concept refer to 3.2.1 below. For full details on

both operation options, refer to Section 8.

The main components of the refrigeration circuit are the Compressor, the Condenser, the

Refrigerant Filter, the Expansion Device, the Hot Gas Bypass and the Air-to-Refrigerant Heat

Exchanger (as described in 3.1.2 above). In addition, there are several control components:

• High Pressure Switch - to shut down the dryer in the event of overpressure of the refrigerant system,

• Low Pressure Switch – to prevent freezing in the event of a system upset, and

• Fan Pressure Switch – to cycle the condenser fan on and off.

These components are connected in a closed

loop with pipes made entirely from high quality

copper, through which the refrigerant flows. All

models use R407C refrigerant.

The refrigeration circuit functions as a closed

loop.

Loading...

Loading...