10

COMMON

5-2) Coupling Installation

• When installing a coupling, do not impact or apply excessive thrust load to the shaft ; otherwise, the bearing may be

damaged or collar may be left.

• Thermal shrinking is the recommended installation method.

• when a sprocket, gear or pulley is coupled with the variator, use within the range of the allowable radial and axial load

defined on our catalog.

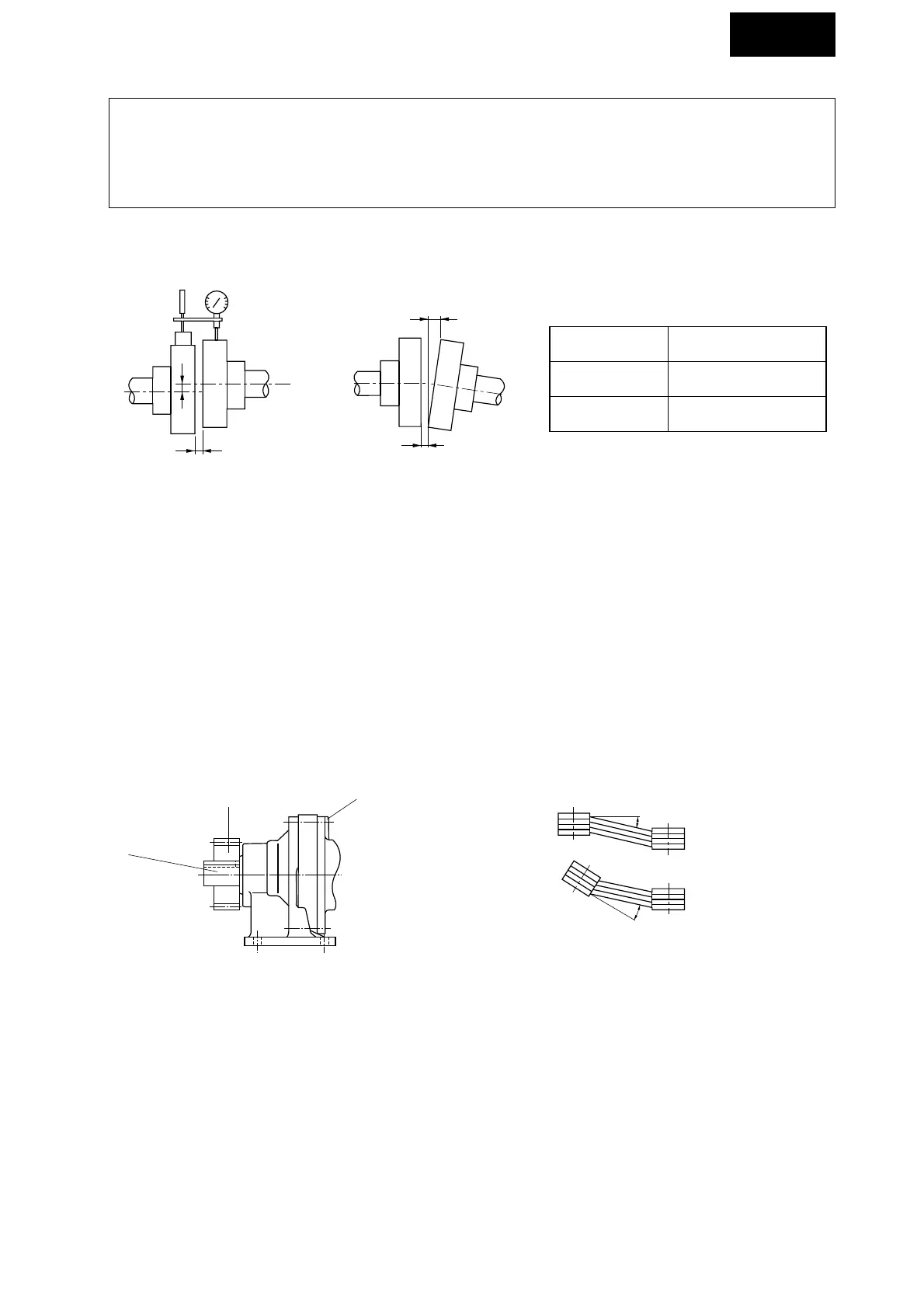

(1) When Using a Coupling

The accuracy of the dimensions (A, B, and X) shown in Fig.5 should be within the tolerance shown in Table 4.

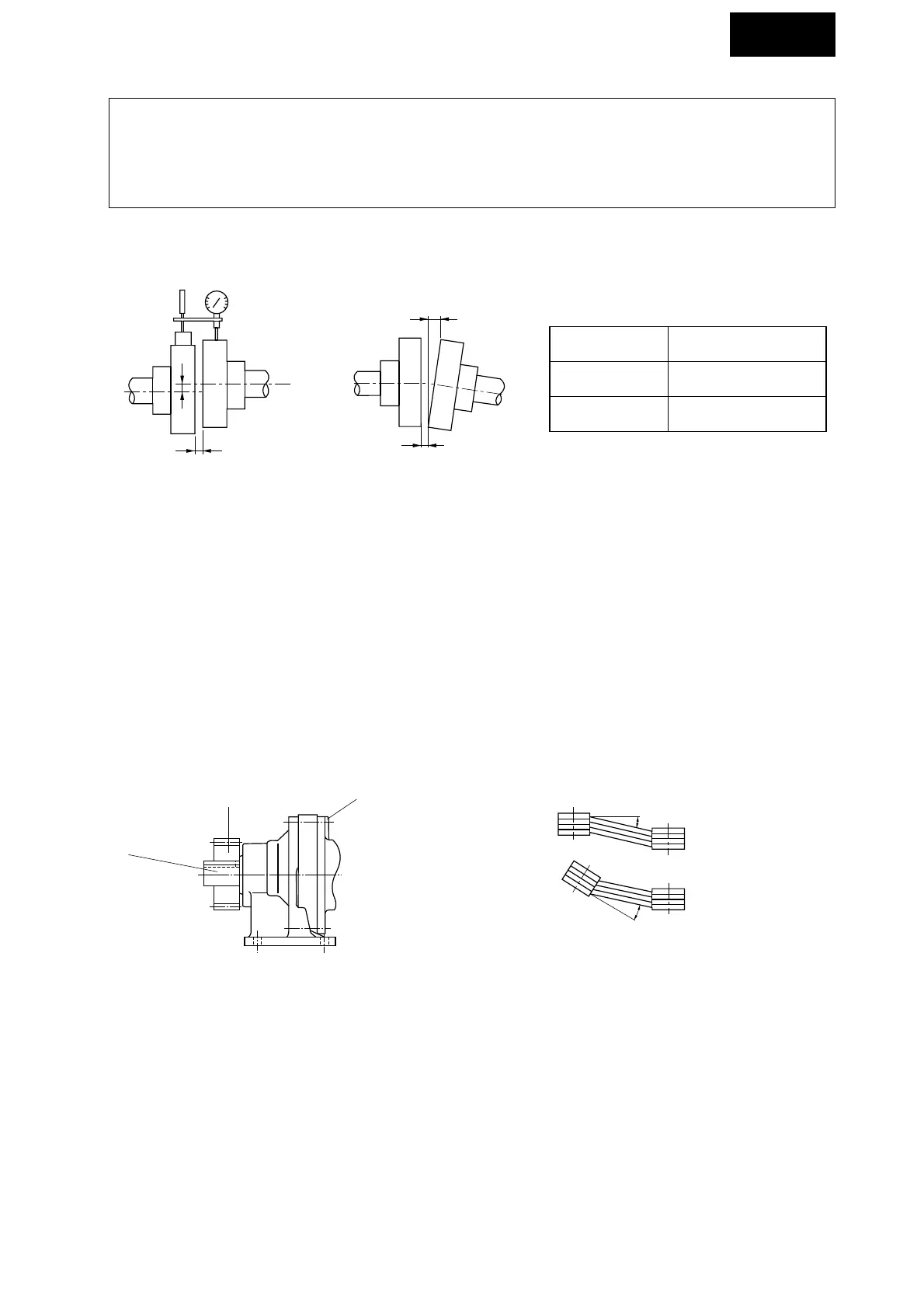

(2) When Using a Chain Sprocket and Gear

• The chain tension angle should be perpendicular to the shaft.

• Refer to the chain catalog for the chain tension.

• Select sprockets and gears whose pitch diameter are three times the shaft diameter or greater.

• Install sprocket and gears so that their point of load application will be closer to the variator side with respect to the

length of the shaft. (Fig.6)

(3) When Using a V-belt

• Excessive V-belt tension will damage the shaft and bearing. Refer to the V-belt catalog for proper tension.

• The parallelism and eccentricity (ß) between two pulleys should be within 20'. (Fig.7)

• Use a matched set with the same circumferential length when more than one belt is to be installed.

• Install V-pulley so that their point of load application will be closer to the variator side with respect to the length of the

shaft.

Dimension A Tolerance

0.1mm or manufacturer’s

specification

Dimension B Tolerance

0.1mm or manufacturer’s

specification

X dimension Manufacturer’s specification

Table 4

Centering Accuracy of Flexible Coupling

Fig. 5

Loading...

Loading...