28

9. Lubricating Oil Cooling Device

9-2) Cooling Water

• For cooling water, use city water or industrial water.

• Table 39 gives a guideling for amount of cooling water supply. Adjust this amount depending on ambient temperature

and operating conditions. It is desirable that Beier Variator be operated with its casing temperature kept within about

60°C .

9-3) Instructions on Starting

• Before starting the main body, be sure to start the oil pump of the lubricating oil cooling device and confirm lubrication.

Allow 30 to 60 seconds lead time for the pump motor, and start the main motor only after the lubricating oil is circulating

well. For the wiring, refer to the diagram on Fig. 11 page14.

9-1) Installation

• Install the horizontal-type Beier Variator horizontally, install the vertical-type Beier Variator vertically, and install the

lubricating oil cooling device horizontally.

• Install this device as close as possible to the main body of the Beier Variator. If it is installed too far apart, the oil pump

will suffer faulty suction and excessive noise, temperature, and insufficient lubrication will result.

• If air is sucked only halfway out of the suctionside piping of the oil pump, the amount of oil will be reduced as a result of

this insufficient suction, thereby causing excessive noise in the oil pump. For this reason, airtightness must be

mantained.

(1) Install this device within 0.5m in a vertical upward location, or within 1.5m in a vertical downward location, and within 3m

horizontally from main body of the Beier Variator. Minimize pipe bands.

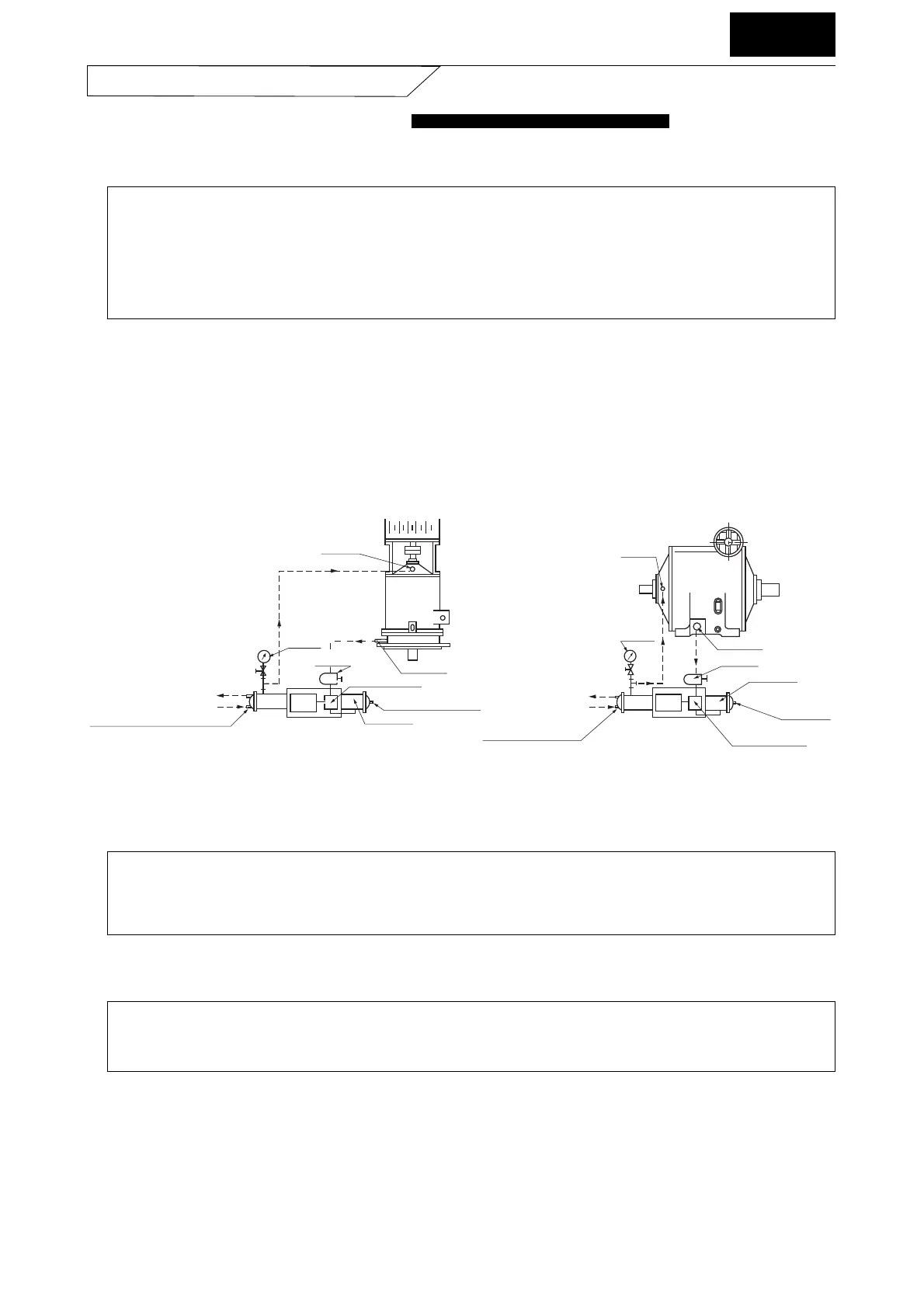

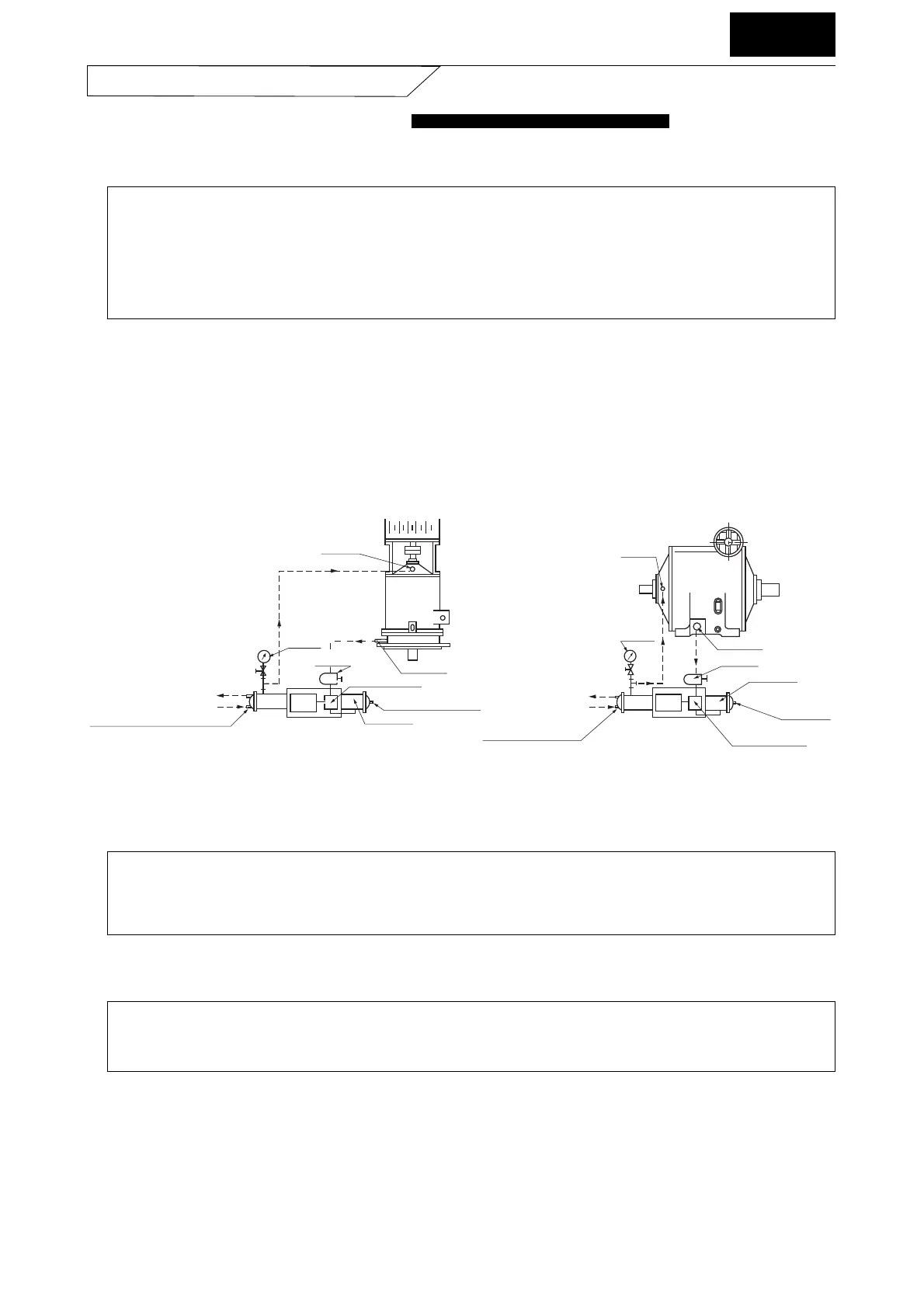

(2) The outline diagram shows both the Beier Variator and its lubricating oil cooling device. According to Fig. 21, install

piping at the site along the broken lines. Use a gas pipe for the piping. Use a 1-1/2B to 2B gas pipe for the Beier Variator

oil outlet, and use a 1B gas pipe for the oil inlet.

Piping materials and pipe joints should be provided by the user since such piping will be installed at the site.

Loading...

Loading...