29

9-4) Daily Inspection and Maintenance of Oil Cooling Device

Table 40 Amount of Cooling Water Supply

Beier frame size

50A, 75A, 100A

50B, 75B

Holizontal Model

Amount of water

supply (L/min)

6–8

10–15

15–20

Vertical Model

150A

200A

100B

150B

(2) Maintenance

(a) Filter cleaning

(i) Clogged filter cartridge may cause the abnormal noise by oil suction shortage of the oil pump. Continuing the

operation under this state may result in supplying shortage of the oil to the variator as well as breakdown of the oil

pump, and may consequently bring the variator itself to burning and other problems.

(ii) Since the filter cartridge is a laminate, you can easily clean the clogged cartridge by turning the handle at the upper

end of the filter. Be sure to turn the handle once or more.

(iii) At the initial operation, since it is easy to clog the cartridge, turn the handle once or more a day for cleaning the

cartridge.

(iv) At a standstill, drain the accumulated dust in the lower part of the filter from the drain plug at the lower end.

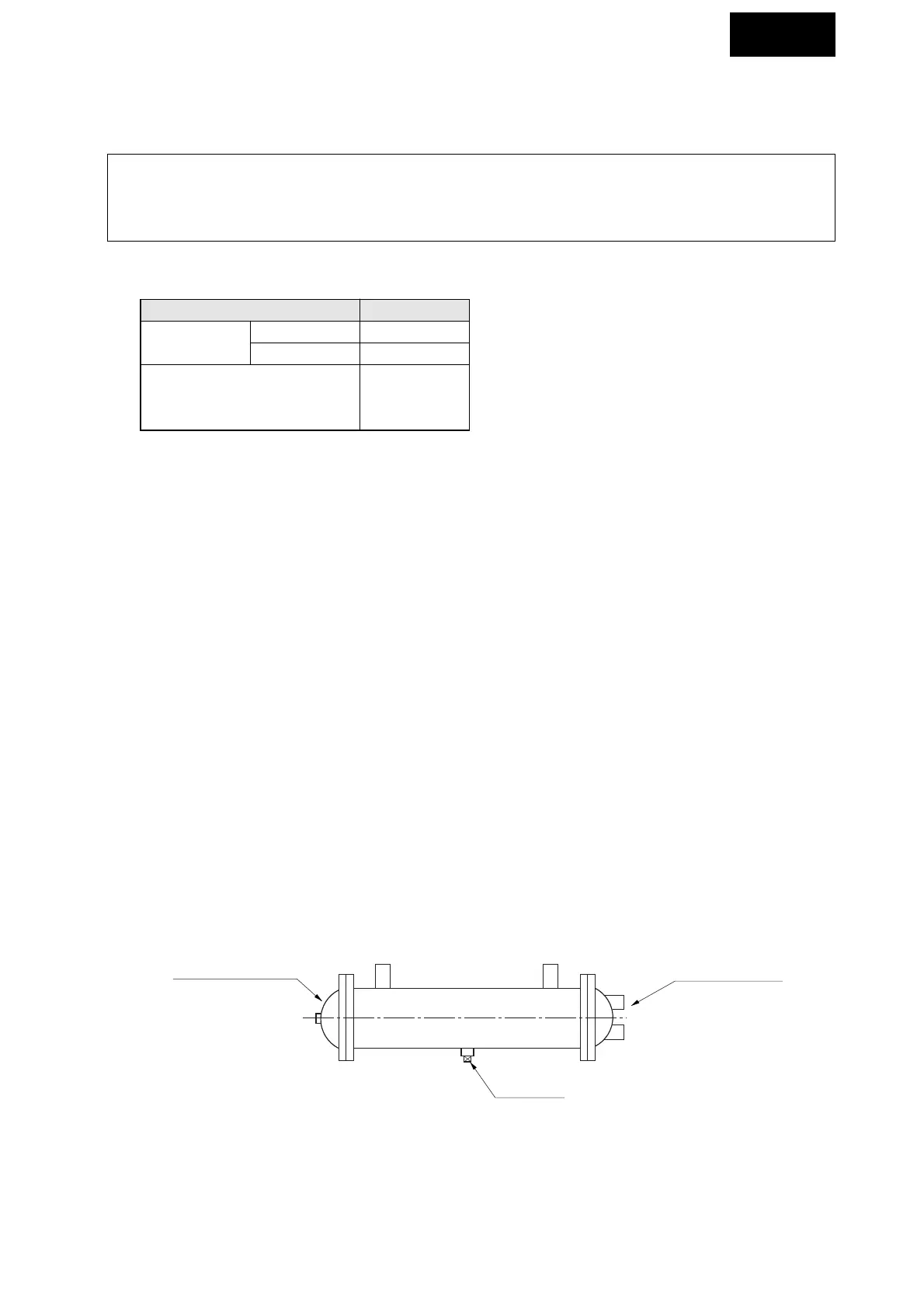

(b) Inspection and cleaning of the oil cooler (cf. Fig.22)

(i) Maintenance and cleaning the oil cooler of the lubricating oil cooling device periodically. The interval depends on the

condition of the lubricating oil or the quality of the cooling water. Be sure to conduct the periodical inspection every 3

to 6 months.

(ii) You can check the cooling water by removing a bonnet in the U-turn side of the cooling water. For checking the

lubricating oil, drain the oil from the oil drain plug.

(iii) At that time, be sure to check the corrosion preventive zinc rod for wear. Replace the rod if it has been worn to less

than half of its original length. You may have to replace it 3 to 6 months depending on the quality of the cooling

water. (There are zinc rods at three places.)

(iv) In winter when you stop the operation at the place where the cooling water freezes, surely drain the water every day.

Even at the ambient temperature that the cooling water freezes, if you can keep the casing temperature of the variator

between 40 to 45 degree, reduce the amount of the cooling water or stop supplying the cooling water.

(1) Daily Inspection

Check the items below to evaluate whether cooling device is operating normally.

1. Is cooling water flowing normally?

2. Is oil clirculating?

3. Is the temperature of BEIER case at 60°C or lower most of the time?

Loading...

Loading...