27

Maintenance of V ring in outdoor type motor

Under aging phenomena or by abrasion, the V ring may become less water-proof.

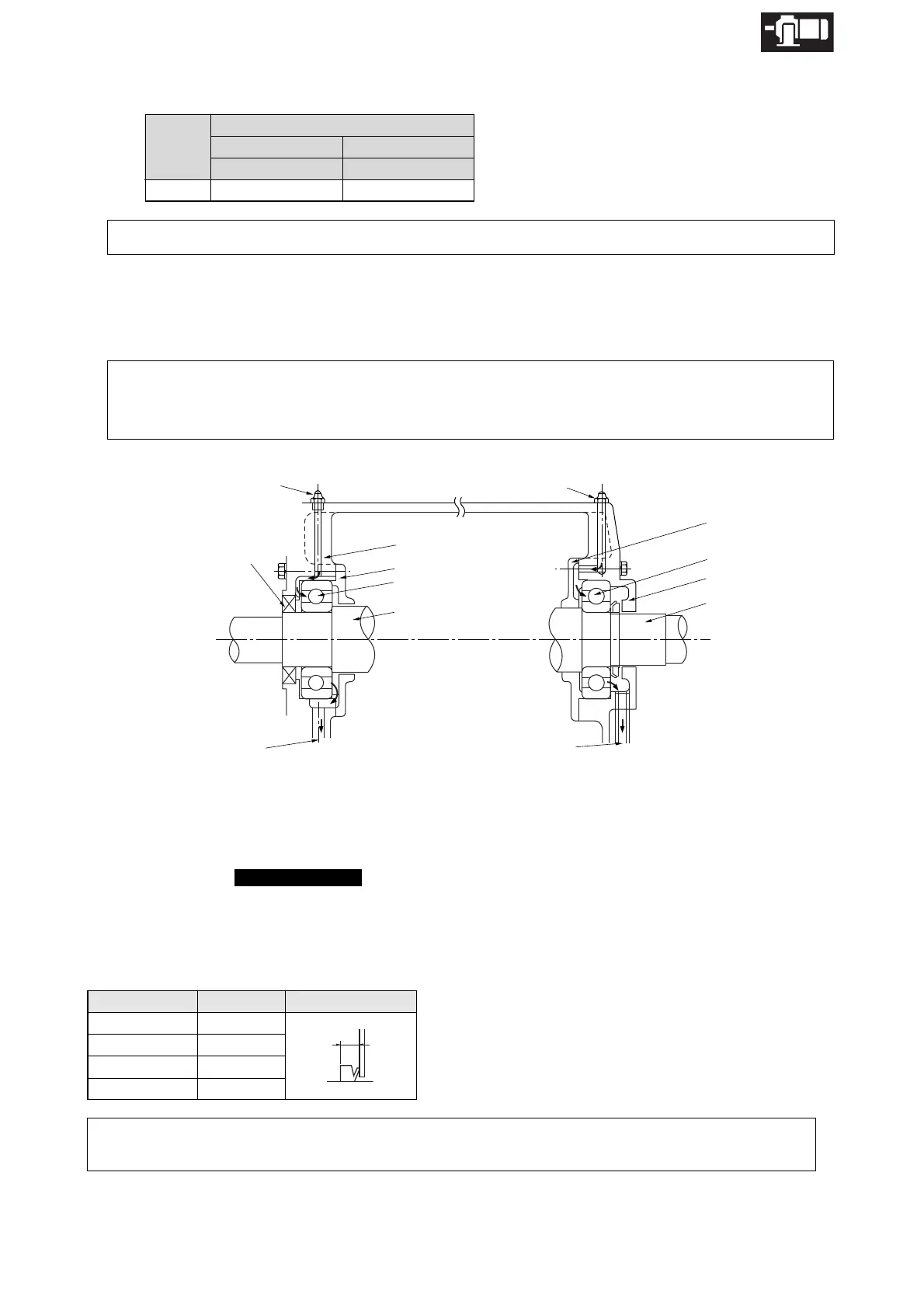

Exchange the V ring once every three years under the normal operation. Refer to the dimension in Table 39 for V ring

attaching dimension.

V Ring

V-10A–V-18A

V-20A–V-38A

V-40A–V-65A

V-70A–V-100A

Dimension B1

4.5 mm

6 mm

7 mm

9 mm

Remarks

Table 39 V Ring Attaching Dimension

• At exchange, apply a small amount of grease to the lip of the V ring.

• We recommend the V ring made by Forsheda.

(2) Recommended Grease

Ambient

temperature

°C

-10~40 UNIREX N2

Shell stamina Grease RL2

Open bearing

Thermal Class B Thermal Class F

Shell OilExxon Mobil

Table 38 Recommended Grease

• Do not use any grease other than those shown in Table 38.

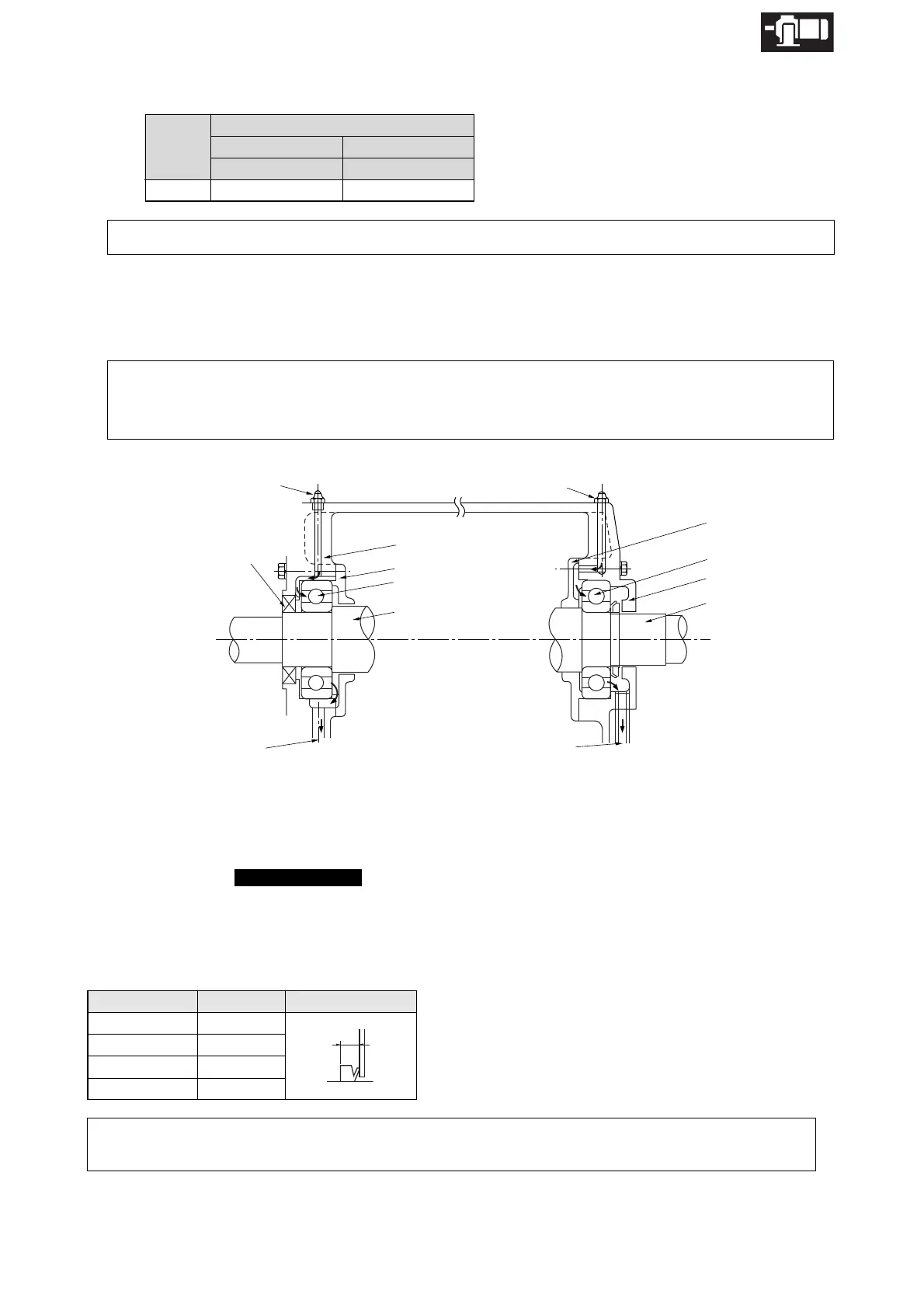

(3) Grease Supply and Discharge (Refer to Fig.20)

1 Remove the discharge plug, discharge old grease and add new grease while unit is operating.

(Grease replenishment at rest cause an insufficient grease change.)

2 Replace the discharge plug after 10min operation.

• Excessive grease may cause temperature rise of bearing or leakage of grease.

• Exceeding the recommended amount of grease does not extend the replenishment interval.

• Don't neglect daily inspection; otherwise abnormal wear and noise from the motor, damage to the bearing may result.

1 Variator side

Fig. 20 Construction of Open Bearing in the Motor

2 Motor end side

Loading...

Loading...