26

8-7) Maintenance of Motor Bearing

The maintenance for Sumitomo standard 3-phase motor is shown below.

(Refer to the respective instruction manuals for the brakemotor , other companies' motor , etc.) Bearing No. and

maintenance methods also differ according to motor size. Before maintenance, check the bearing type on the rating plate

and Table 36.

Bearing type

Shield bearing

Motor frame size

Note

No grease nipple

Load side Opposite side

Smaller than #225 All

Open bearing With grease nipple and discharge plug#250 —

Table 36 Bearing Type

Grease replenishment for open bearing

(1) Grease Replenishment Intervals and Quantity

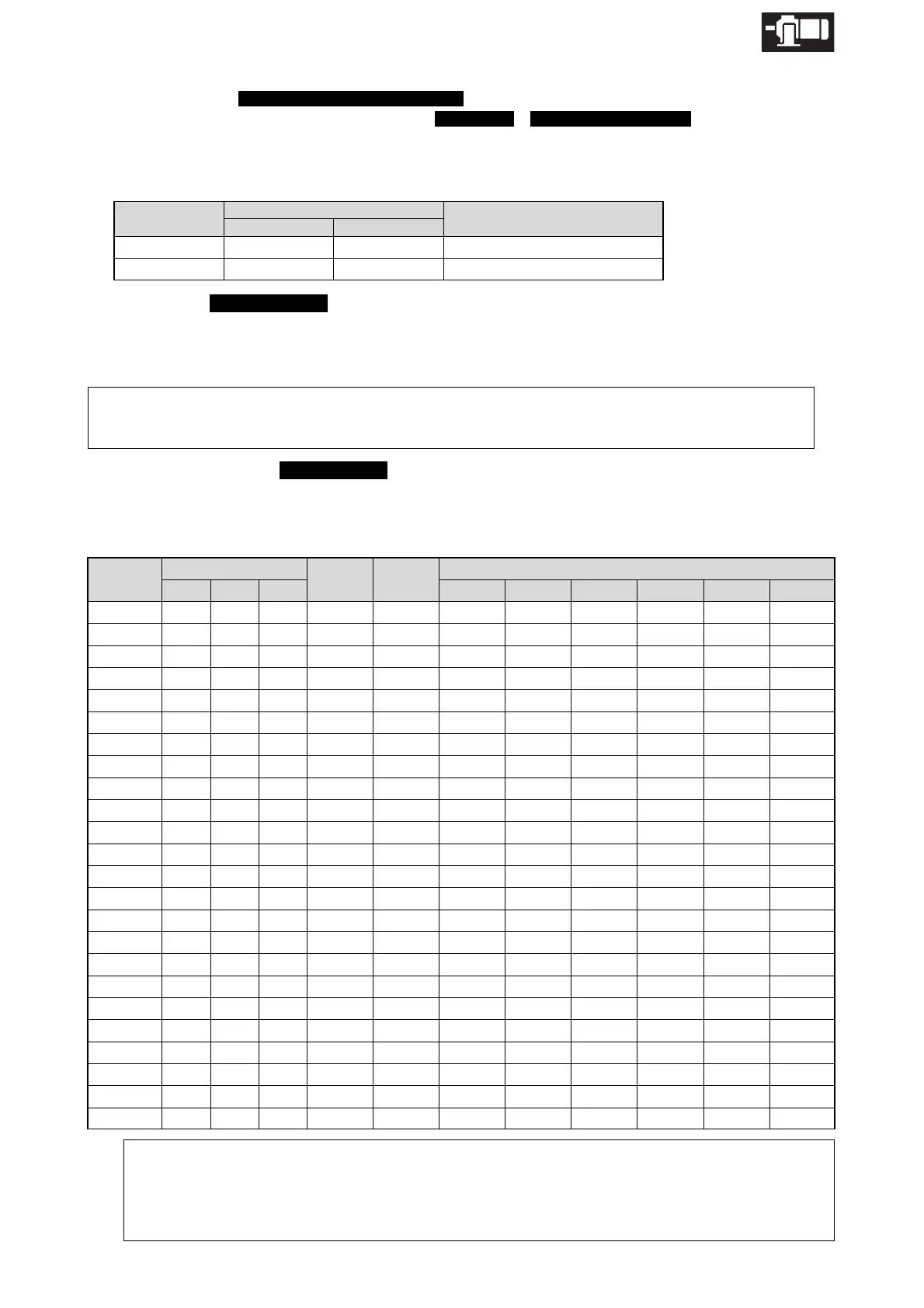

Check the bearing No, on the rating plate, refer to Table 37 and supply grease.

Bearing No.

Dimension (mm)

Initial q'ty

(g)

Replensihed

q'ty (g)

Grease replenishment interval (h) for each rotation speed (

r/min

) of motor

750r/min 900r/min 1000r/min 1200r/min 1500r/min 1800r/min

I. D O. D W

6314 70 150 35 200 40 8500 7000 6000 5000 3500 2500

6315 75 160 37 230 45 8500 6500 6000 4500 3500 2500

6316 80 170 39 260 50 8000 6500 5500 4500 3000 2500

6317 85 180 41 300 55 7500 6000 5000 4000 3000 2000

6318 90 190 43 350 60 7000 5500 5000 4000 2500 2000

6319 95 200 45 400 65 7000 5500 4500 3500 2500 1500

6320 100 215 47 450 70 6500 5000 4500 3500 2000 1500

6321 105 225 49 500 75 6000 5000 4000 3000 2000 1500

6322 110 240 50 550 80 6000 4500 4000 3000 2000 1000

6324 120 260 55 700 100 5500 4000 3500 2500 1500 1000

6412 60 150 35 200 40 8500 7000 6000 5000 3500 3000

6413 65 160 37 230 45 8000 6500 6000 4500 3500 2500

6414 70 180 42 300 55 8000 6500 5500 4500 3000 2500

NU314 70 150 35 120 40 4000 3500 3000 2500 1500 1000

NU315 75 160 37 150 45 4000 3000 3000 2000 1500 1000

NU316 80 170 39 200 50 4000 3000 2500 2000 1500 1000

NU317 85 180 41 250 55 3500 3000 2500 2000 1500 1000

NU318 90 190 43 300 60 3500 2500 2500 2000 1000 1000

NU319 95 200 45 350 65 3500 2500 2000 1500 1000

NU320 100 215 47 400 70 3000 2500 2000 1500 1000

NU321 105 225 49 450 75 3000 2500 2000 1500 1000

NU322 110 240 50 500 80 3000 2000 2000 1500 1000

NU324 120 260 55 650 100 2500 2000 1500 1000

21312 60 130 31 70 30 1500 1000 1000 800

• "Initial q'ty" shows quantity of grease for disassembled and cleaned inside of the unit. Paint 1/3 of grease with the

inner lace of bearing and replenish other with inside of the unit.

• "Replenished q'ty" shows quantity of grease for every replenishment.

• For intermittent operation, replenish grease every 3 years or less.

• For long-term stoppage replenish grease just after operating.

Table 37 Grease Replenishment Intervals and Quantity for Open Bearing

Maintenance of shield bearing

Shield bearing is supplied with good lubricating grease in advance. Although grease replenishment is not necessary,

exchange of bearing every 20,000 operational hours or once in 3-5 years in normal operating condition at the time of

overhaul, enables more unfailing operation.

• Use CM class (clearance) bearing for the motor bearing.

• Use grease (Kyodo Yushi : Multemp SRL) lubricated bearing for the sealed motor bearing.

• Reduce the supply interval when the operating conditions are severe.

Loading...

Loading...