13

(2) How to attach of torque arm (option)

Attention of attachment

1 Attach torque arm to the application machine side of the reducer.

2 Attach retainer parts of torque arm (refer Fig.11) to release extra force between the reducer and the driven shaft.

(Retainer is to be supplied by customer.)

3 Never lock the torque arm completely with locking bolts and such.

4 Attach shock-absorbing material between torque arm and attachment bolt (or spacer).

5 Use bolt which meets JIS standard of screw strength ranking by 10.9 or above.

6 Bolts must be made to lock when a torque arm is used. (The method to lock is to use U-nut or spring washer, or to

supply adhesive for locking screw, etc.)

Note: As shock-absorbing material, rubber bushes and spring washers are prepared.

By use and operating condition, different shock-absorbing materials are recommended.

• In the case of one direction operation : Spring washers or rubber bushes

• In the case of start-stop operation : Spring washers

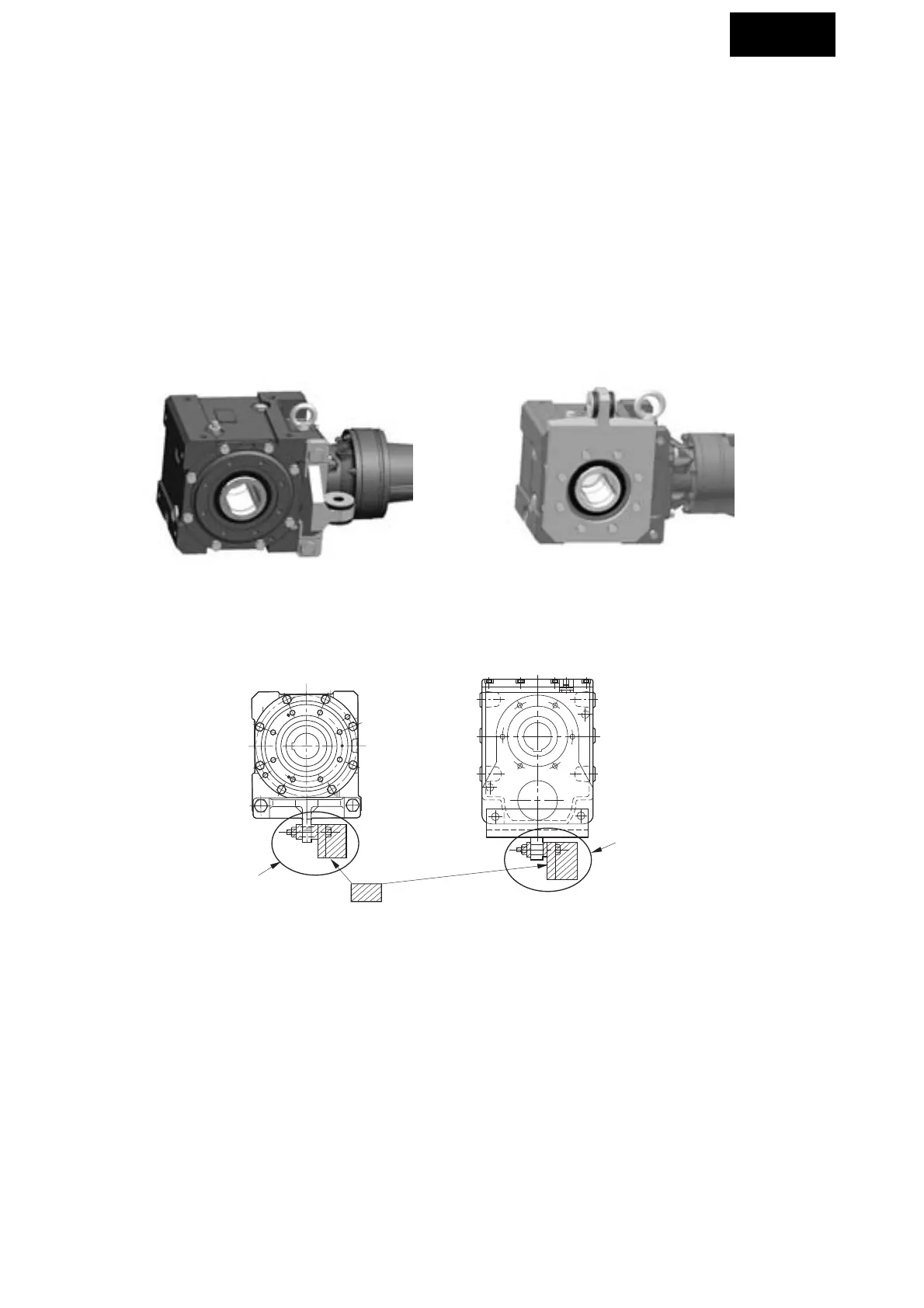

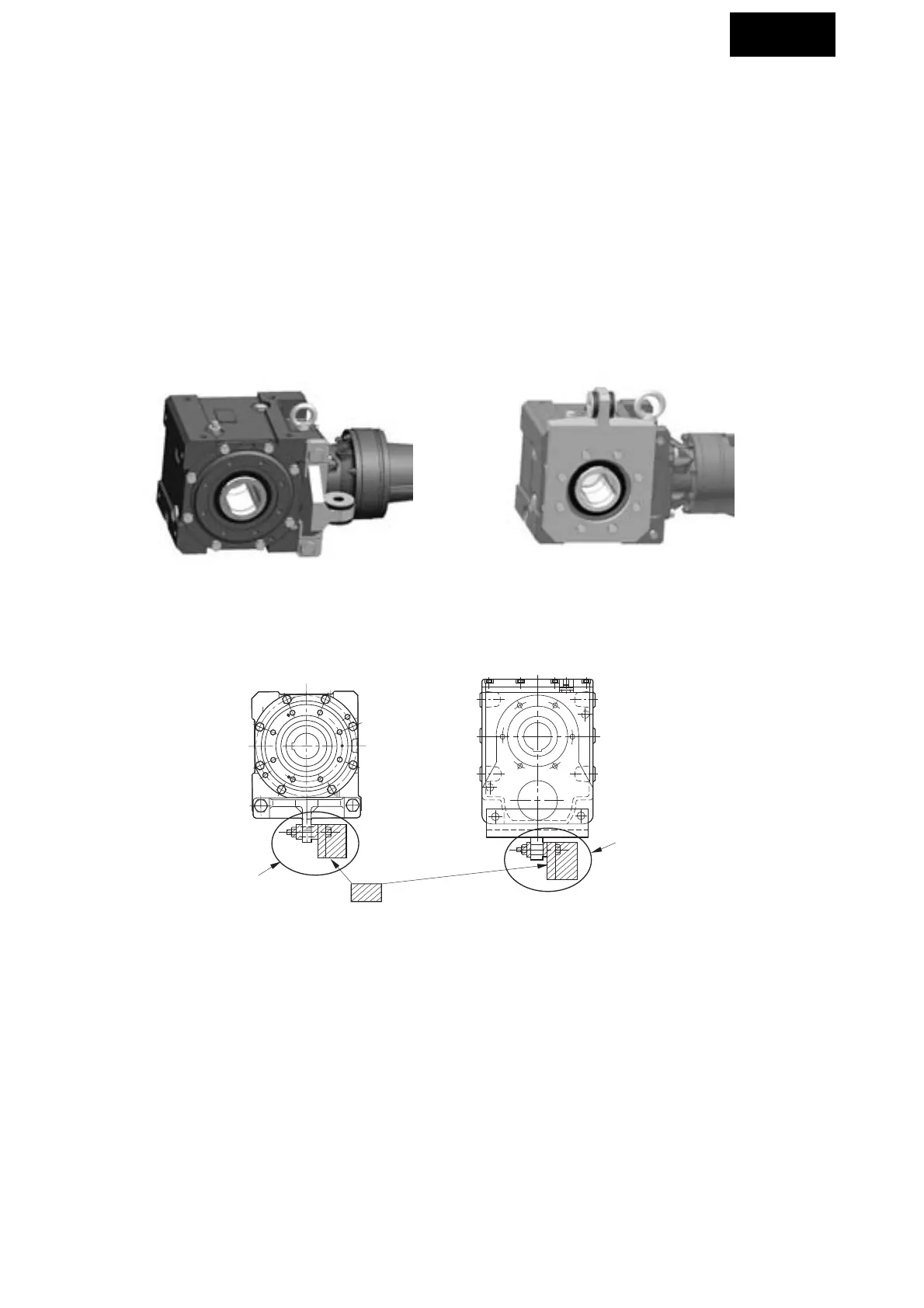

Attachment type torque arm (option) Banjo type torque arm (option)

Part of is to be supplied by customer.

Loading...

Loading...