1.BEFORE OPERATION

2.OPERATION PRECAUTIONS

3.CHIEF TECHNICAL SPECIFICATIONS

1. In order to resist rust before machine head packing, all parts are smeared with thick rust-resist ant oil. After

packing, perhaps in a relativey long storage and transportation period, the oil will harden and absorb dusts. Th-

erefore, it's necessary to clean the oil and dustswith neat soft cloth and gasoline.

2. The machine are examined and checked throughly before leaving the factory. But in a long jounce, the ma-

chine may be shaken intensely and some parts become loose. It's advisable to test again and turn the driving

gears with hands so as to make sure if turning is difficult, run foul of each other or if there is non-uniform block or

irregular voice. If so, the machine should be adjusted until every part is normal before driving.

3. Operation are forbidden before pouring oil in the plate.

5. Confirom the given electric voltage and phase on motor nameplate.

6. The date of manufacture is shown on the inspection certification.

1. When the power supply is open or the machine is operating , don't touch the machine needle with your hands.

2. When the machine is running, don't stretch your hands in the mat of the thread stitch bar.

3. When the machine head is turning ,and the "V" belt is being disassembled , the electric supply should be

cut off.

4. When the operator is leaving the machine,cut out the power supply.

5. When the machine is running,no heads,handsor any other things are allowed to get close

to the uper wheels,"V"belts bobbin winder and motor.

6. Not until the machine is stops running can you disassemble the belt cover, protection

cover or other protecting devices?

7. The machine head's surface can't be cleaned with dilutes such as banana oil.

8. Don't put your finger into the finger guard when you feed material by hand.

4. When the machine is in operation, the direction of the upper wheel are anti-clockwise (viewing from the

outer part of the upper wheel).

6

22

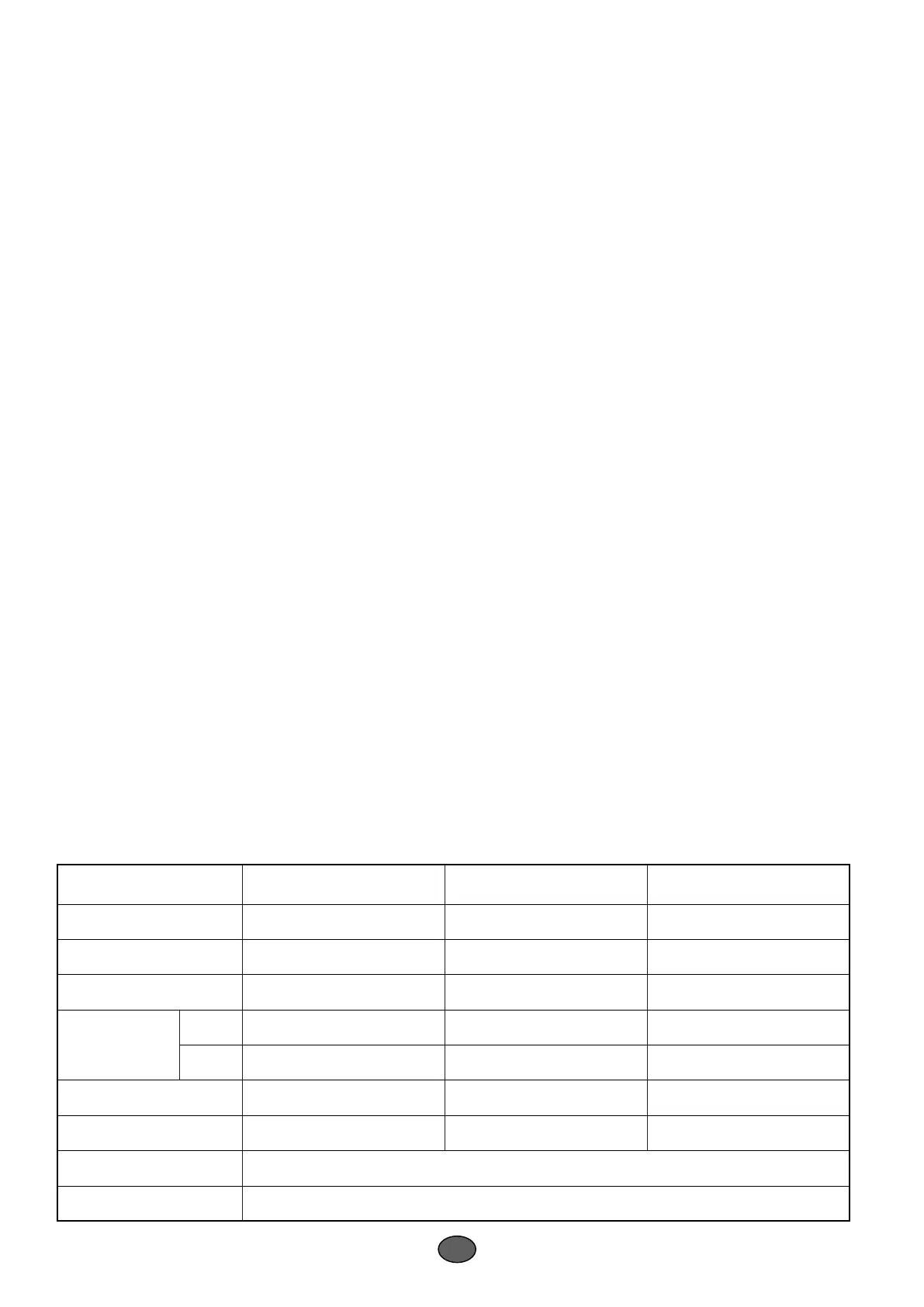

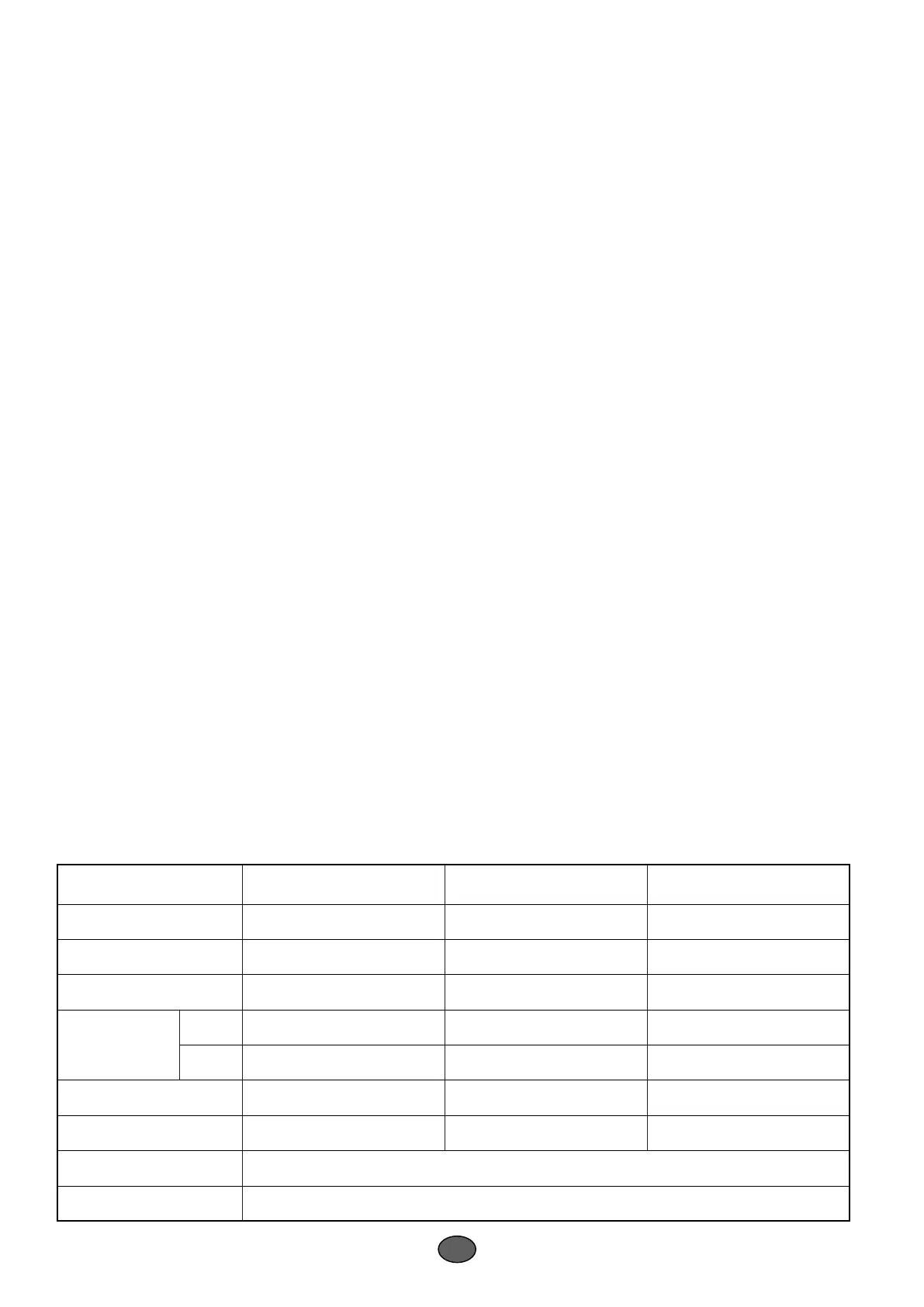

Model Number

Thin materials

4000SPM(5000SPM)

5mm

6mm 6mm 6mm

13mm 13mm 13mm

DB×1 9 #~1 8 #

10# White oil

Middle thick materials Thick materials

3000SPM(4000SPM)

2800SPM(3500SPM)

5mm

7mm

DP×5 16#~23# DP×5 16#~23#

220V/550W

Sewing material

Sewing speed(Max)

Maximum stitch length

Motor power

Hand

control

Knee

control

Pressure foot

liftting high

KM-2510A

KM-2520A

Standard

Standard

1.6 Standard

KM-2510B

KM-2520B

KM-2510BL

KM-2520BL

Needle

Hook

Lubrication oil

Loading...

Loading...