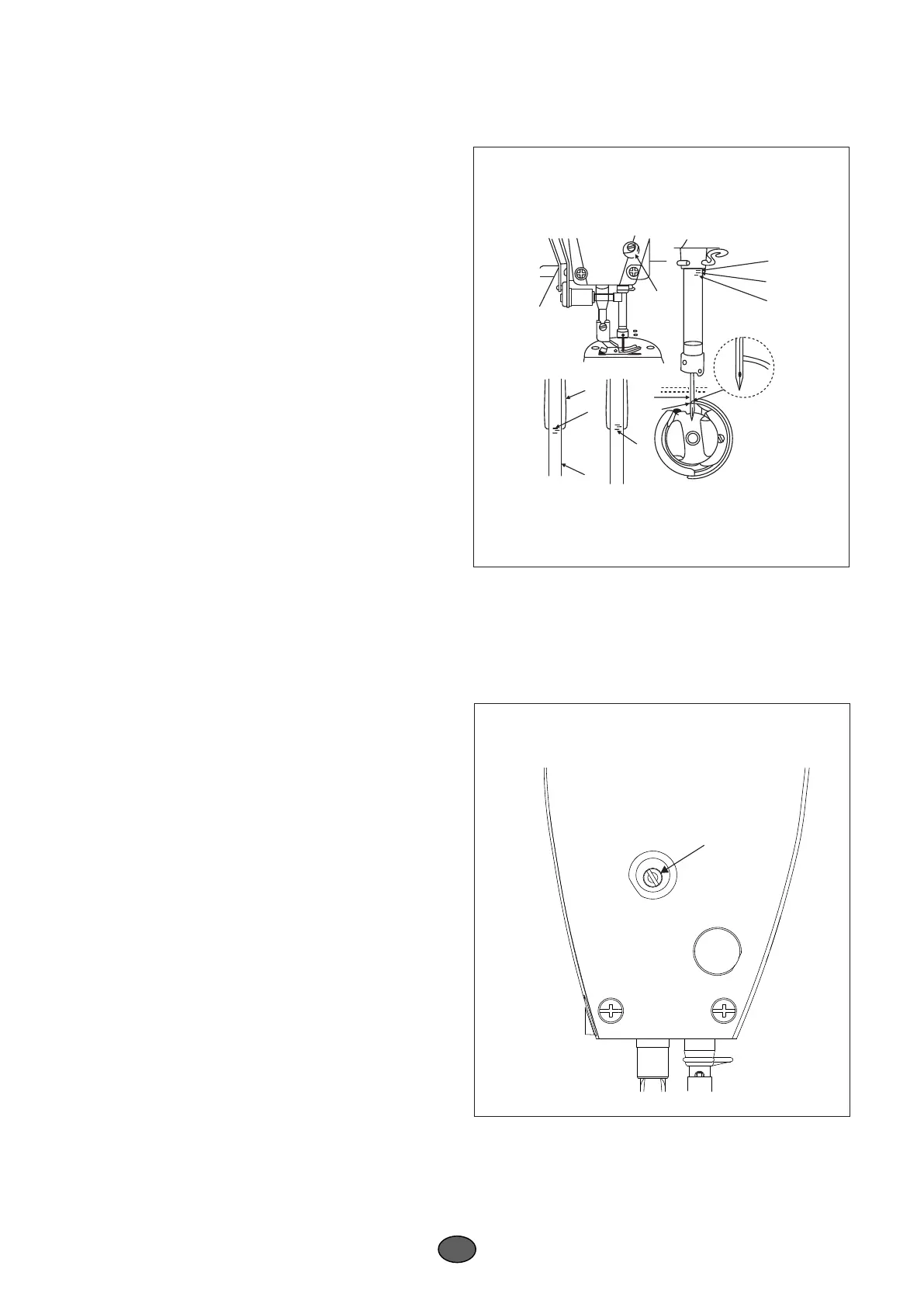

23.NEEDLE-TO-HOOK RELATIONSHIP(FIG.28)

1. Adjust the timing between the needle and the hook as

follows:

1) Turn the handwheel to bring the needle bar down

to the lowest point of its stroke , and loosen setscrew①.

*Adjusting the needle bar height

2) Align marker line "A" on needle bar② with the

bottom end of needle bar lower bushing③, then tight

setscrew①.

*Adjusting position "A" of the hook

3) Loosen the hook setscrews, turn the handwheel,

and align marker line B on ascending needle bar② with

the bottom end of needle bar lower bushing③.

4) After making the adjustments mentioned in the

above steps align hook blade point⑤ with the center of

needle④. Provide a clearance of 0.04mm to 0.1mm betw-

een the needle and the hook, then securely, tighten the

hook setscrews.

*Note that the type of hook to be substituted for, when replacing the hook, shall be in the sewing machine of

original assemblage.

Fig.28

①

②

③

④

⑤

A

A

C

B

B

6

32

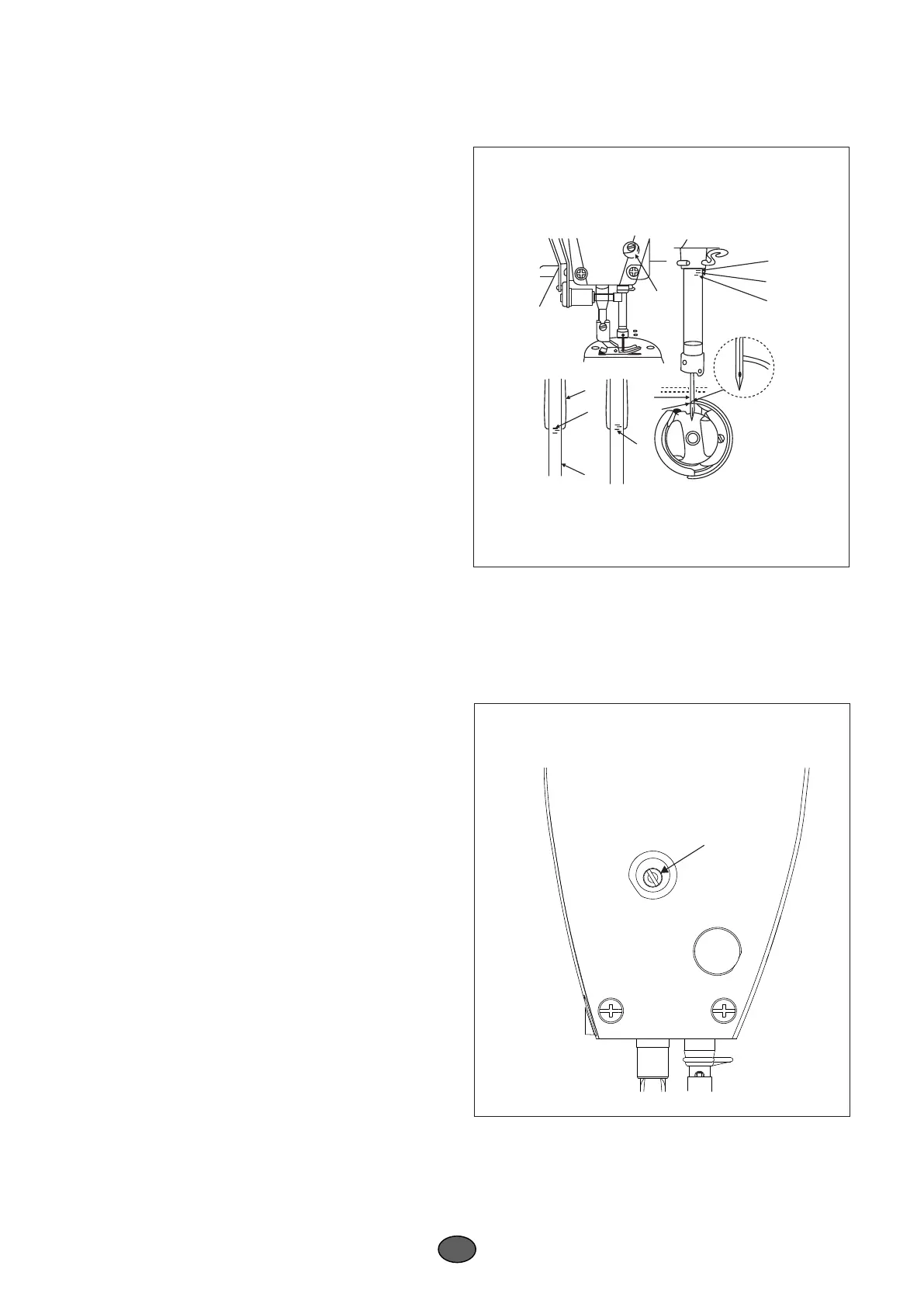

24.ADJUSTING THE HEIGHT OF THE PRESSER BAR(FIG.29)

1. Loosen setscrew①, and adjust the presser bar height

or the angle of the presser foot.

2.after adjustment, securely tighten the setscrew.

Fig.29

①

Loading...

Loading...