Housing

q 0V

w Comparative output

e

+

V

n ASSEMBLY OF CONNECTOR

q Using a suitable cable having the following specifications, prepare its end

with a stripper, etc., as given in the figure below.

Further, the cable extension can be 100m or less with 0.3mm

2

, or more, cable.

m FUNCTIONAL DESCRIPTION

, ERROR MESSAGES

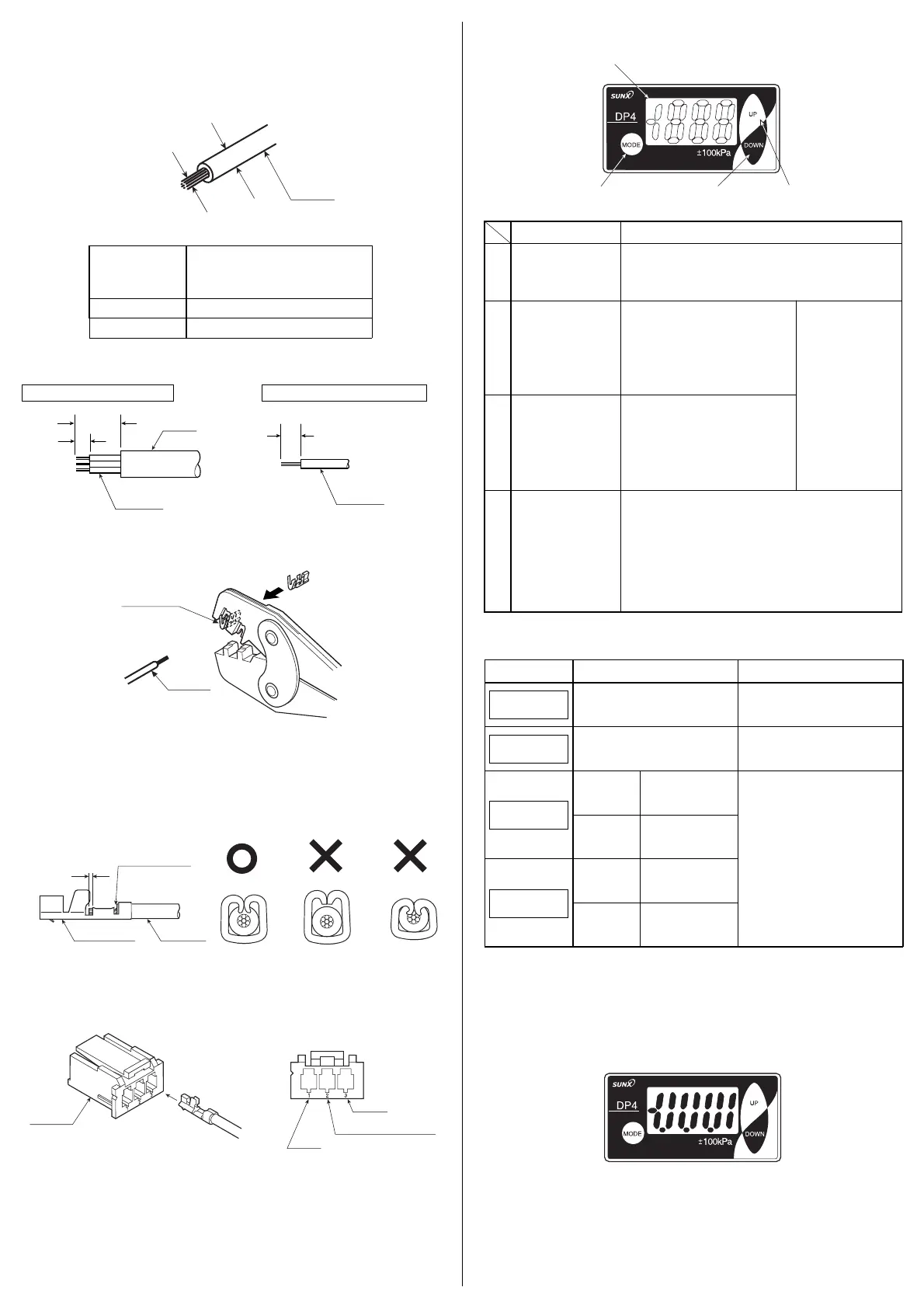

. ANALOG BAR DISPLAY

䢇 Pressure changes are displayed in an analog fashion by using LCD bar. Hence,

any sudden changes in pressure can be detected at a glance.

䢇 The analog bar display shows the measured pressure, in steps of 14% F.S.

approx.

w Setting the connector pin in the groove of the exclusive crimp tool as shown

in the figure below, insert the lead wire into the connector pin and crimp.

e After crimping, make sure to confirm that the crimping is proper, as shown in

the figure below.

In case the crimping is incorrect, cut the cable and repeat the procedure from

Step q.

r As shown in the figure below, insert the connector pin till the end of the hous-

ing.

After inserting, make sure to confirm that the locking is proper by pulling

lightly (10N or less) at the cable.

• Pin position

Note:

Do not reuse a connector pin which has been crimped once or inserted into the housing,

as its performance cannot be guaranteed.

Please procure the optional connector (CN-63) (10 Nos./set) or the recommended

product.

A connector attached cable (CN-63-C2) (cable length: 2m) is also available.

In case of cabtyre cable In case of single lead wire

20mm

2.2mm

2.2mm

Sheath

Lead wire

Lead wire

1

432

<Recommended>

Crimping tool: YC-690R manufactured by J.S.T. MFG CO., LTD.

Connector pin: BXA-001T-P0.6 manufactured by J.S.T. MFG CO., LTD.

<Recommended>

Housing: XAP-03V-1 manufactured by J.S.T. MFG CO., LTD.

Cause

Overcurrent due to short-circuit.

Pressure is being applied during zero-

point adjustment.

Vacuum

pressure type

Applied pressure exceeds

the lower limit (reverse

pressure) of displayable

pressure range.

Applied pressure

exceeds the upper

limit of displayable

pressure range.

Vacuum

pressure type

Applied pressure

exceeds the upper

limit of displayable

pressure range.

Applied pressure exceeds

the lower limit (reverse

pressure) of displayable

pressure range.

Positive pressure

and compound

pressure types

Positive pressure

and compound

pressure types

Corrective action

Switch off the power supply and

check the load.

Applied pressure at the pressure

port should be brought to atmos-

pheric pressure and zero-point

adjustment should be done again.

Applied pressure should be brought

within the rated pressure range.

Error message

E - 3

E - 1

- - -

-

- - -

Lead wire

Connector pin

Core wire

should be visible

0.5 to 1mm

Connector pin Lead wire

Lead wire diameter

0.16 to 0.32mm

2

(AWG 25 to 22)

φ1.2 to φ1.8mm

Conductor

cross-section area

(Note)

Wire material

Tin plated, soft, twisted copper wire

Lead wire

Lead wire diameter

Conductor

cross-section area

• Cable specifications

3

1

/

2

digit LCD display

q

with red and

green backlight

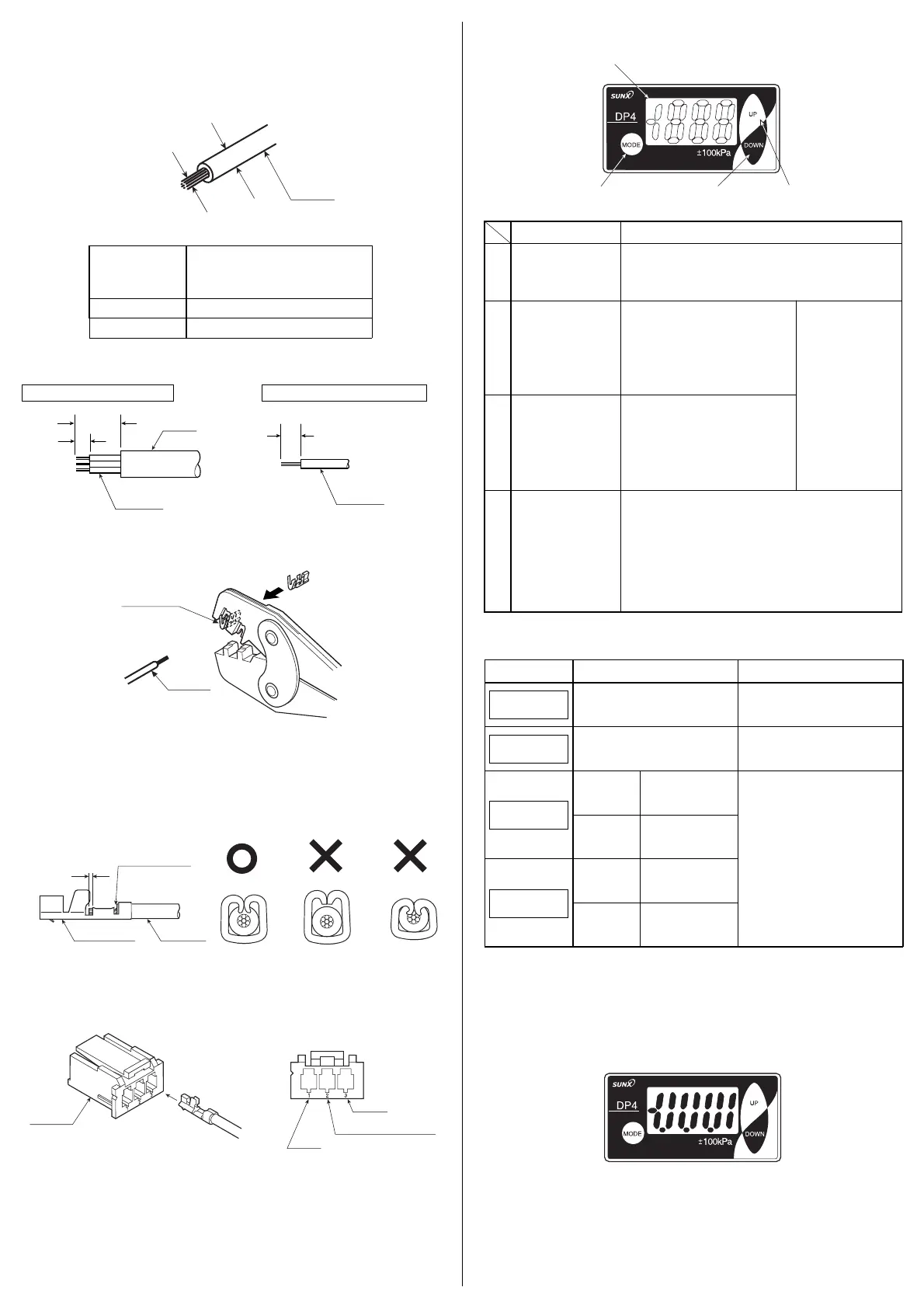

Description Function

• Displays measured pressure, settings, error messages and

key-protect status.

• Red display when comparative output is ON.

• Green display when comparative output is OFF.

• In the initial setting mode and supple-

mentary setting mode, pressing the

key changes the setting item.

•

In the pressure value setting mode,

pressing the key changes the set value.

•

In the sensing mode, pressing the key

continuously for 4 sec., or more, dis-

plays the peak hold value.

w

UP key

e

DOWN key

r

MODE key

• In the pressure setting mode, pressing the key changes the

setting item.

• In the sensing mode, pressing the key continuously for 4 sec.,

or more, can set/cancel the key-protect.

•

In the sensing mode, pressing both UP key and MODE key

simultaneously changes the mode to the initial setting mode.

Whereas, pressing both DOWN key and MODE key simulta-

neously changes the mode to the supplementary setting

mode.

• In the sensing

mode, if both keys

are simultaneously

pressed continu-

ously, zero-point

adjustment is done.

• In the initial setting mode and supple-

mentary setting mode, pressing the

key changes the set conditions.

•

In the pressure value setting mode,

pressing the key changes the set value.

•

In the sensing mode, pressing the key

continuously for 4 sec., or more, dis-

plays the bottom hold value.

()

⁄0 MEMORY BANK FUNCTION

䢇 The memory bank function allows two types of set values to be stored: Set

Values 1 to 3 (P-1 to P-3) and Set Values 4 to 6 (P-4 to P-6).

This makes it possible to the change set values quickly.

(Refer to ‘⁄2 SETTING, Pressure value setting mode’.)

Note: If the wire length is 2m or more, use 0.3mm

2

, or more,

cable.

Ramco Innovations (800) 280-6933 www.sunxsensors.com

Loading...

Loading...