SG Series Boilers – Installation and Service Manual

21

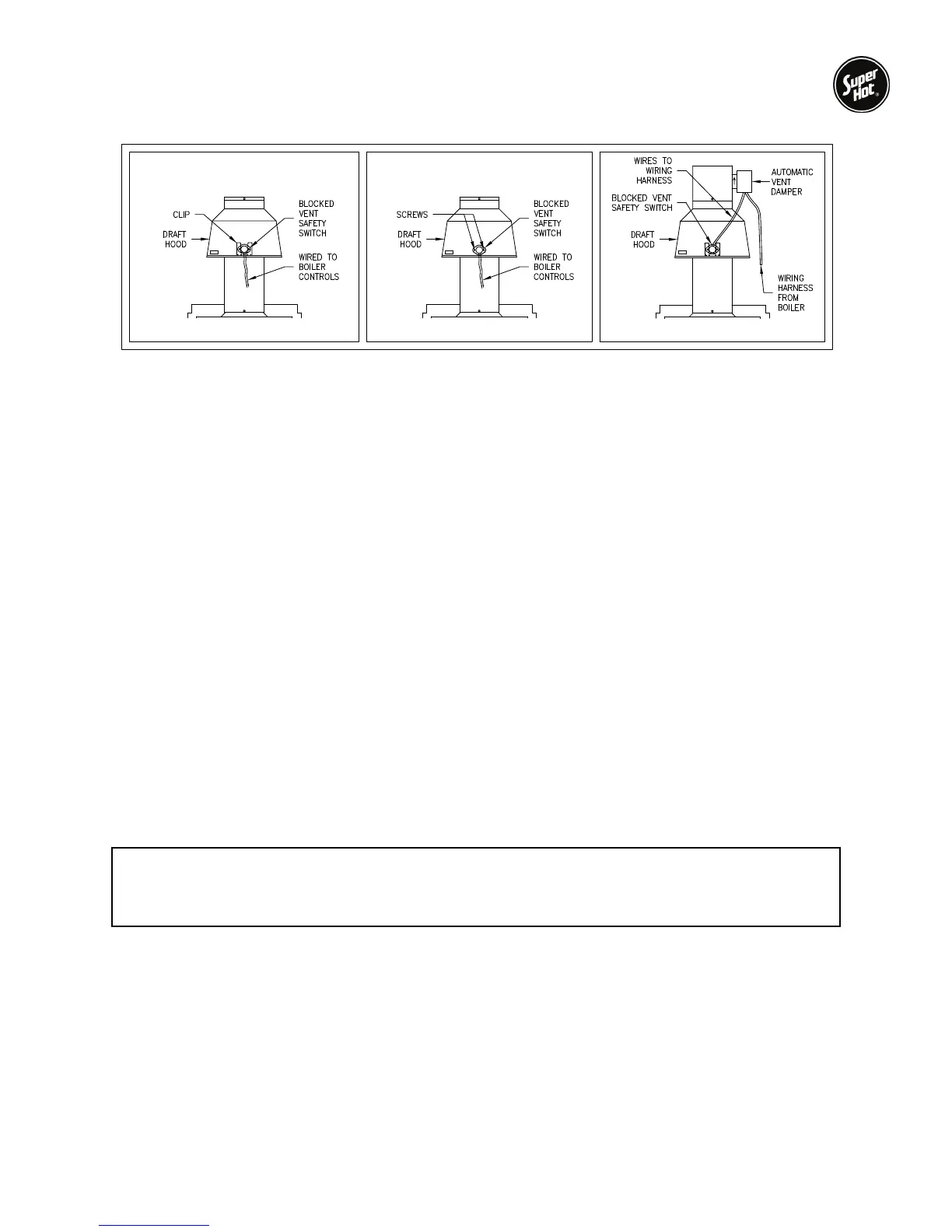

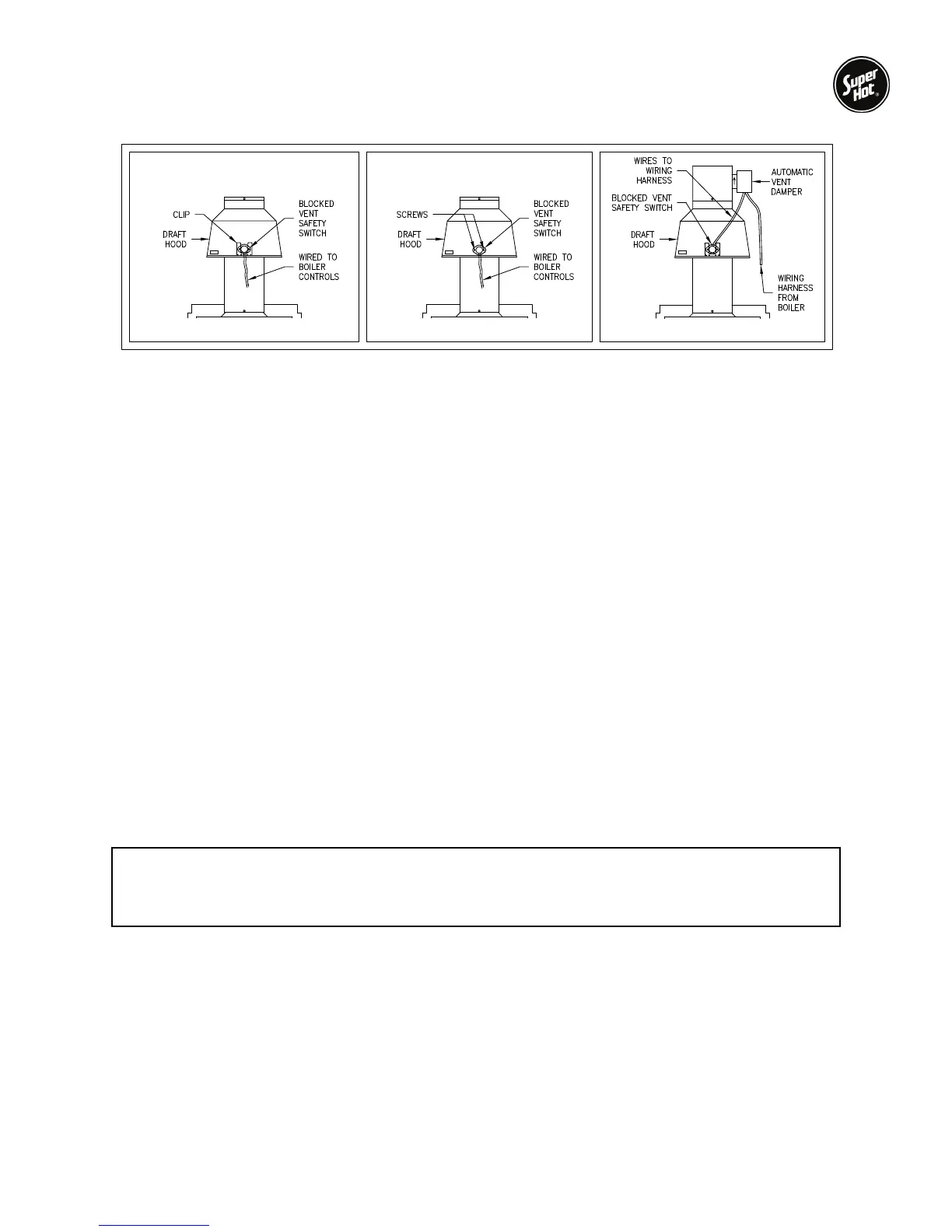

ALTERNATE 1 ALTERNATE 2

ALTERNATE 3

FIGURE 6 - MOUNTING LOCATION OF BLOCKED VENT SAFETY SWITCH AND WIRE ROUTING

2.10 BOILER PIPING SYSTEM

The boiler piping system of a hot water boiler connected to heating coils located in air handling units

where they may be exposed to refrigerated air circulation must be equipped with flow control valves or

other automatic means to prevent gravity circulation of the boiler water during the cooling cycle.

The boiler, when used in connection with a refrigeration system, must be installed so the chilled medium

is piped in parallel with the boiler with appropriate valves to prevent the chilled medium from entering the

boiler.

2.11 CORROSION PREVENTION (INTERNAL)

The use of oxygen barrier tubing is recommended to protect the system and its components (e.g. pump)

from corrosion. Should your system include "non-oxygen barrier” tubing please contact the factory or a

heating professional for recommendations.

If freeze protection is required, use an inhibited propylene glycol solution which is specifically designed

for hydronic heating systems and always maintained at a neutral pH (e.g. Fernox Alphi-11 or equivalent).

Follow the supplier’s instructions for proper use and maintenance. Do not use automotive antifreeze.

Some types of chemical additives can cause problems (e.g. accelerated corrosion, reduced efficiency,

etc.) and could result in premature failure of the boiler heat exchanger and/or system components,

especially when not properly used or maintained. Corrosion is a preventable condition and is not covered

by the product warranty.

2.12 SYSTEM OPERATING REQUIREMENTS

WARNING

If you do not follow these instructions exactly, a fire or explosion may result causing property

damage, personal injury or loss of life.

Avoid unnecessary replenishment of system water. It can allow oxygen to enter the system and cause

serious corrosion problems. As well, minerals dissolved in the water supply will precipitate when heated;

minerals preferentially deposit in the heat exchanger. Do not draw water from the heating system for

cleaning, flushing, etc.

Super Hot SG series boilers are designed for use in closed loop systems and are not intended for open

systems, as in heating pool water or systems where water is constantly replenished. Operating the boiler

in an open system will result in premature failure of the heat exchanger. Super Hot boilers may be used

to heat water in open systems indirectly by installing a heat exchanger, such as the Super Hot C-Coil, to

separate open and closed systems.

Heating systems with low temperature return water may cause flue gas moisture to condense on the

boiler heat transfer surfaces, causing corrosion and restricting flue gas flow. Also, low temperature return

Loading...

Loading...