SG Series Boilers – Installation and Service Manual

25

3.4 AQUASTAT ADJUSTMENT

An optional aquastat may be installed to control the main burner firing by sensing outlet water

temperature. The optional aquastat should be set a minimum of 20°F (10°C) above the setting of the

high limit of the integrated boiler controller.

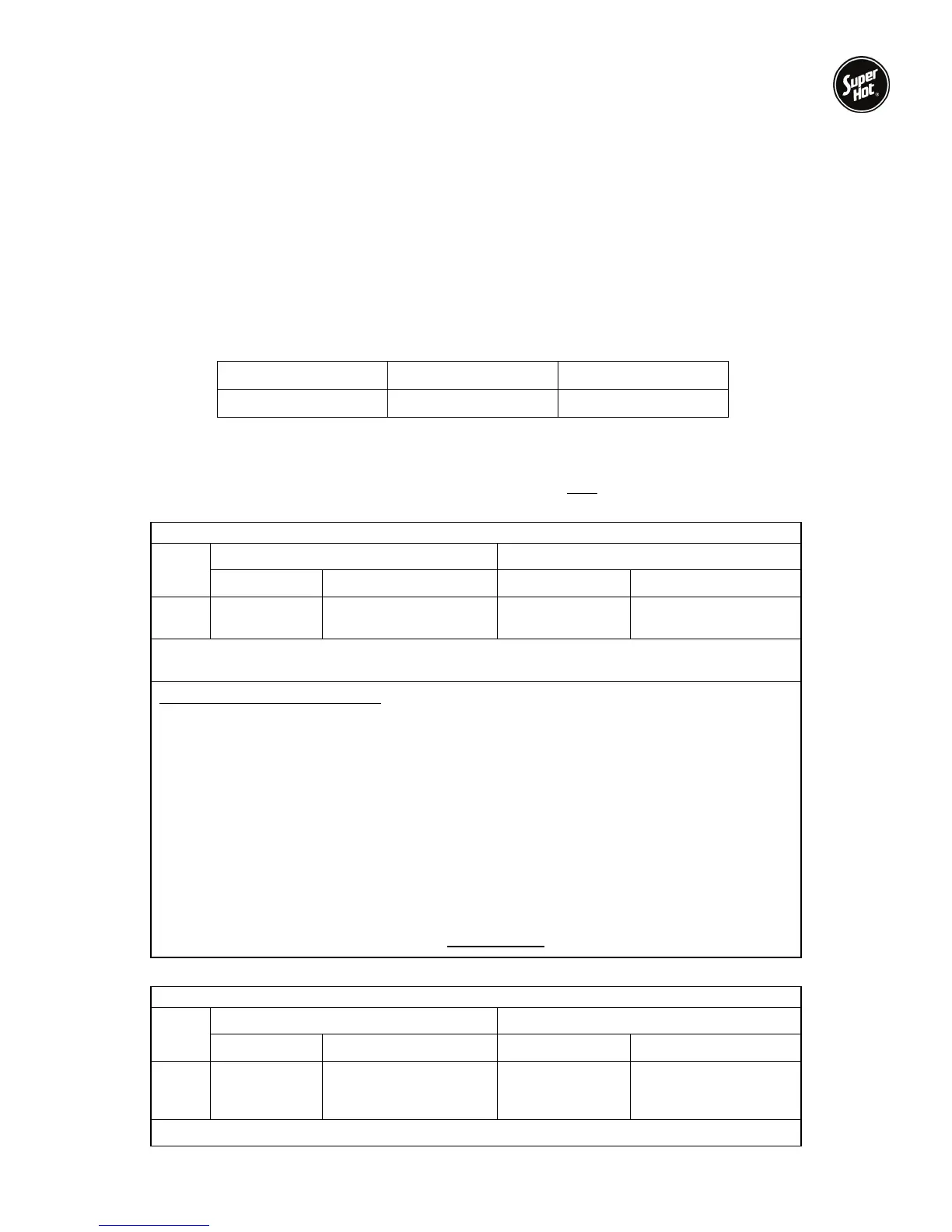

3.5 GAS MANIFOLD PRESSURE

The designated manifold pressures are as shown in the table below. A 1/8” NPT tapping is provided on

the manifold or gas valve for connecting a manometer to check this pressure. Both natural gas and

propane models are furnished with gas valves which have a built in gas pressure regulator. If necessary,

adjust to the proper value by removing cap and turning adjusting screw clockwise to increase manifold

pressure or counterclockwise to decrease manifold pressure.

Model Natural Gas Propane

SG

3.5” W.C. 10.0” W.C.

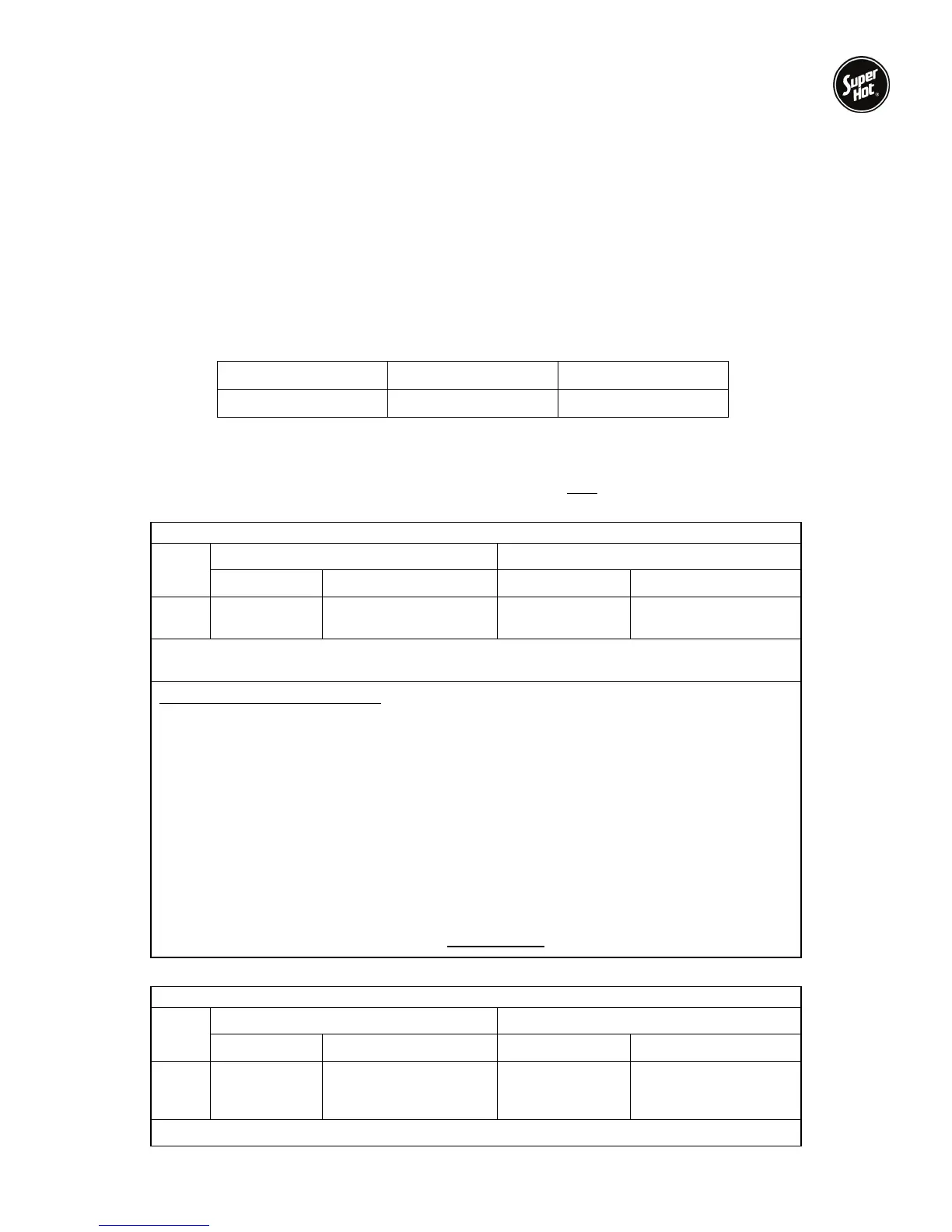

3.6 CHECK INPUT & ORIFICES

For safety, the input shown on rating plate must not be exceeded. Check with the table below that

the orifice size and input rate shown on the rating plate match your

application, i.e. boiler model, fuel

type, and altitude. See SG Dimensions and Specifications section to find your boiler model's input rate.

FOR CANADA

Natural Gas Propane

Model

0 to 2,000 feet 2,000 to 4,500 feet 0 to 2,000 feet 2,000 to 4,500 feet

SG

#43 orifice

standard input

#44 orifice

10% derate input

#54 orifice

standard input

#55 orifice

10% derate input

NOTE: For elevations above 4,500 feet reduce high altitude input 4% for each additional 1000 feet.

Reference Natural Gas and Propane Installation Code B149.1, 3.22 High Altitude Installations

Example of High Altitude Derate

Boiler: SG-270

Altitude: 5,500 feet

Standard Input (0 to 2,000 ft) = 270,000 Btu/h (from page 3)

High Altitude Input (2,000 to 4,500 ft) = Derate Standard Input by 10% (see above table)

= 270,000 Btu/h x (1 - 0.10)

= 270,000 Btu/h x 0.90

= 243,000 Btu/h

% Reduction for additional 1000 ft = 4% x 1 = 4%

Input at 5,500 ft = Derate High Altitude Input by 4%

= 243,000 Btu/h x (1 – 0.04)

= 243,000 Btu/h x 0.96

= 233,280 Btu/h

FOR UNITED STATES OF AMERICA

Natural Gas Propane

Model

0 to 2,000 feet Over 2,000 feet 0 to 2,000 feet Over 2,000 feet

SG

#43 orifice

standard input

Input must be reduced

4% for each 1000 feet

above sea level. *

#54 orifice

standard input

Input must be reduced

4% for each 1000 feet

above sea level. *

*Reference National Fuel Gas Code ANSI Z223.1, 8.1.2 High Altitude.

Loading...

Loading...