2

DELIVERY OF YOUR MACHINE

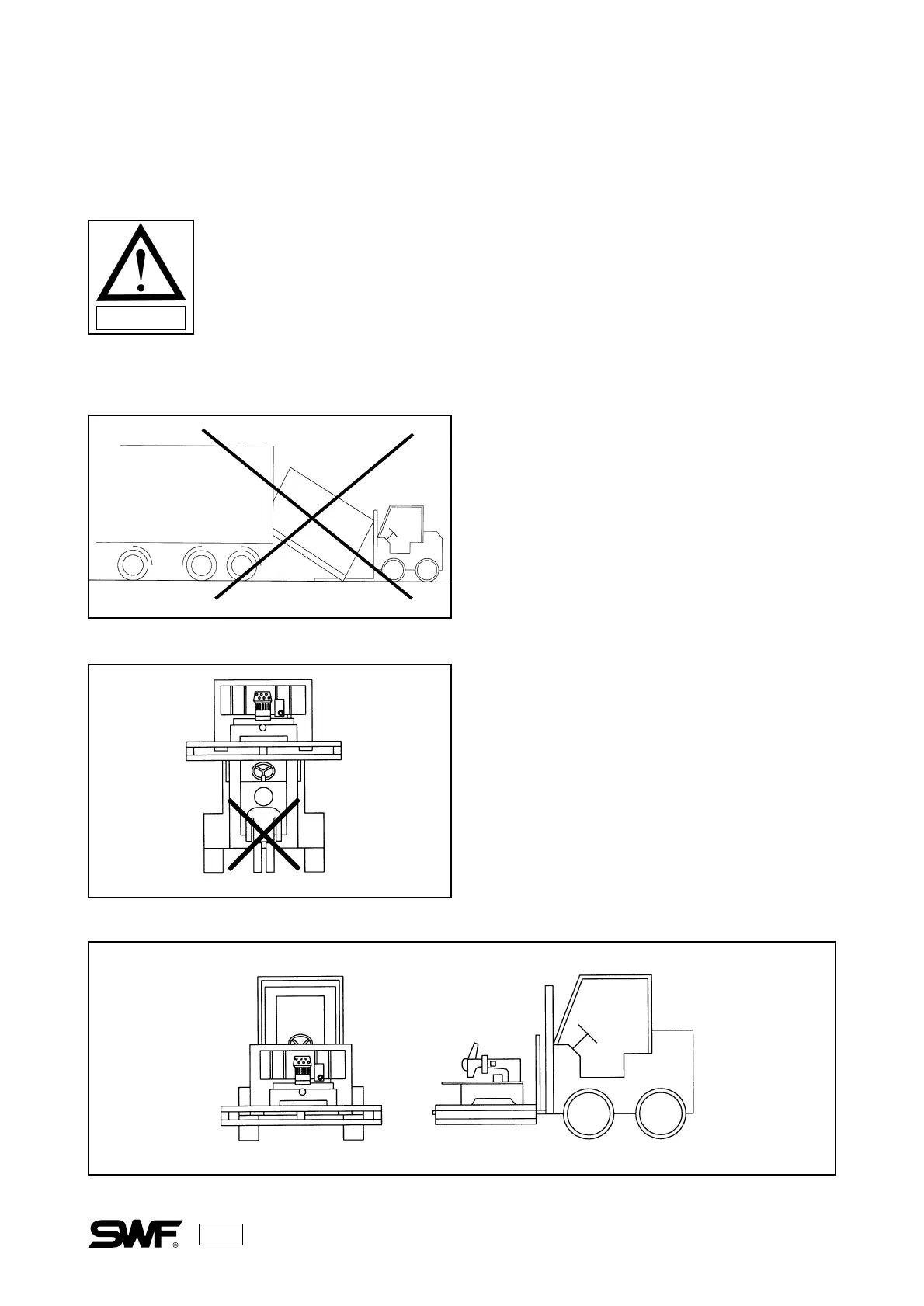

1) When removing the crated machine from the

delivery truck, be sure to keep the crate in a

horizontal position to prevent damage to the

machine or injury to the workmen.

2) All workers should wear safety shoes and, when

moving the machine, be sure to hold the machine

by the handles on the right and left sides.

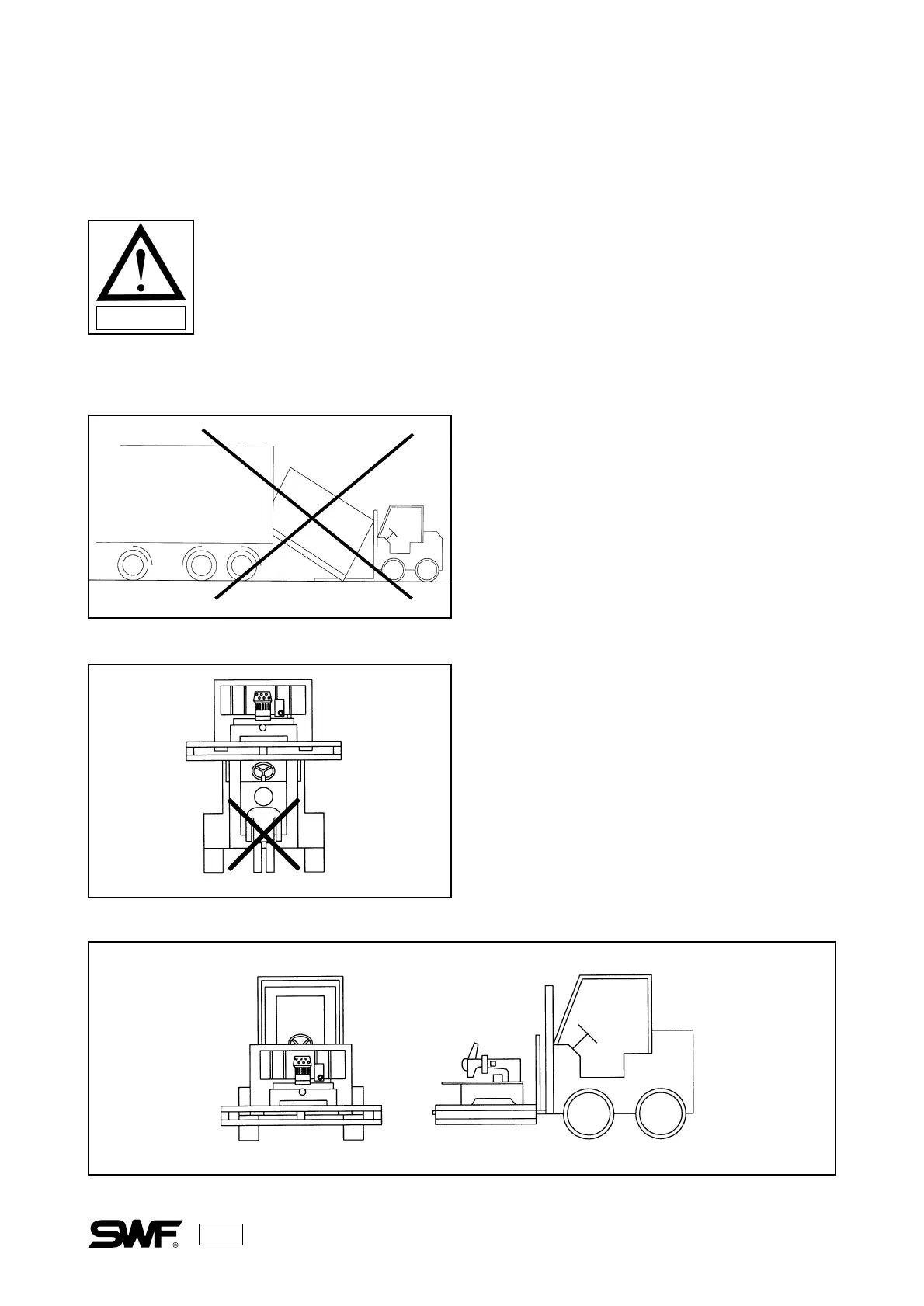

3) When using a forklift, make sure all helpers are

out of the way of the moving equipment. Make

sure that all obstacles in the path of the forklift

are removed. Ensure that the size and the power

of the forklift is sufficient to support the

machine. Place the machine in the center of the

forklift arm and lift it carefully to maintain the

weight balance.

DANGER

Safeguarding your machine begins with delivery. Only trained and experienced

persons, familiar with any special transporting instructions, should be employed

to move your new machine.

Loading...

Loading...