17

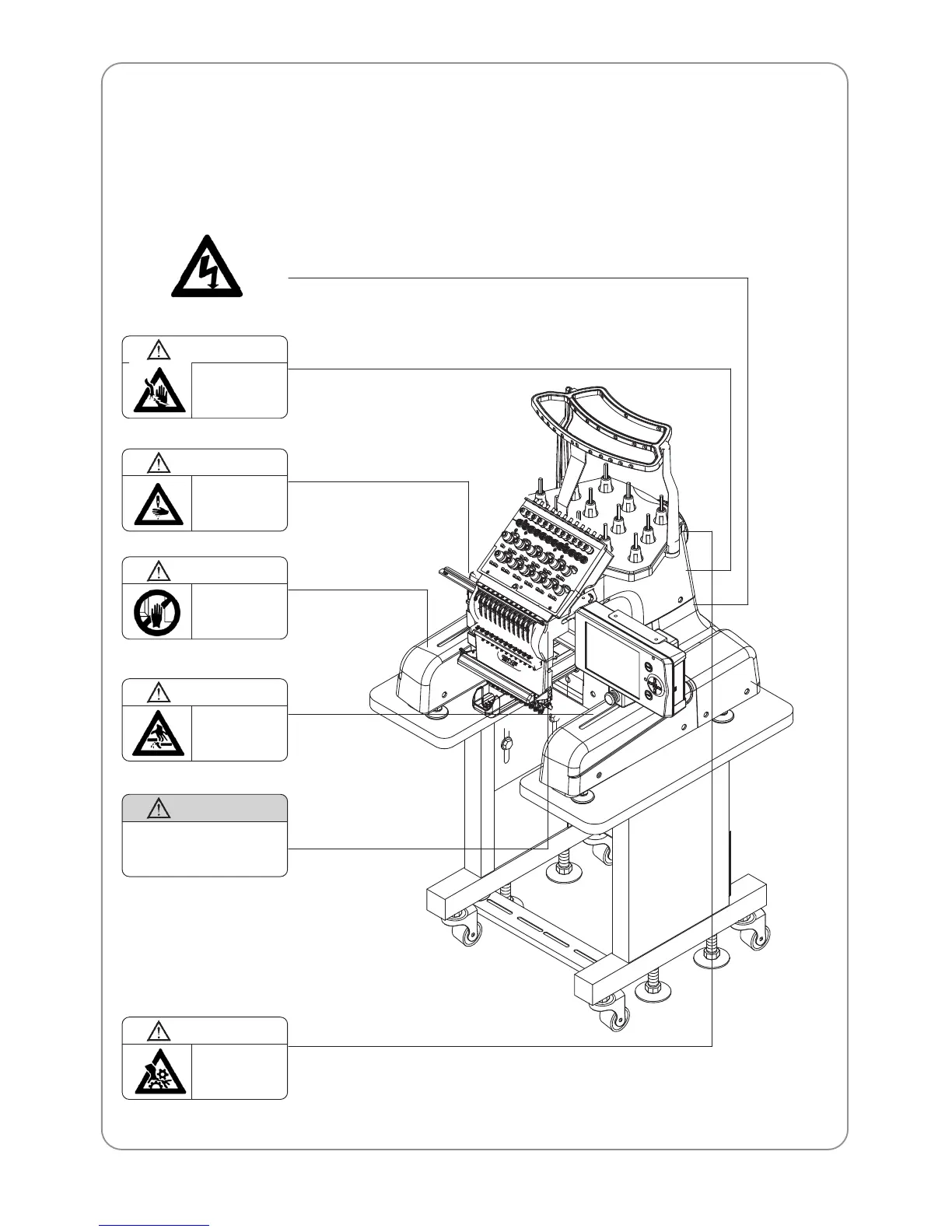

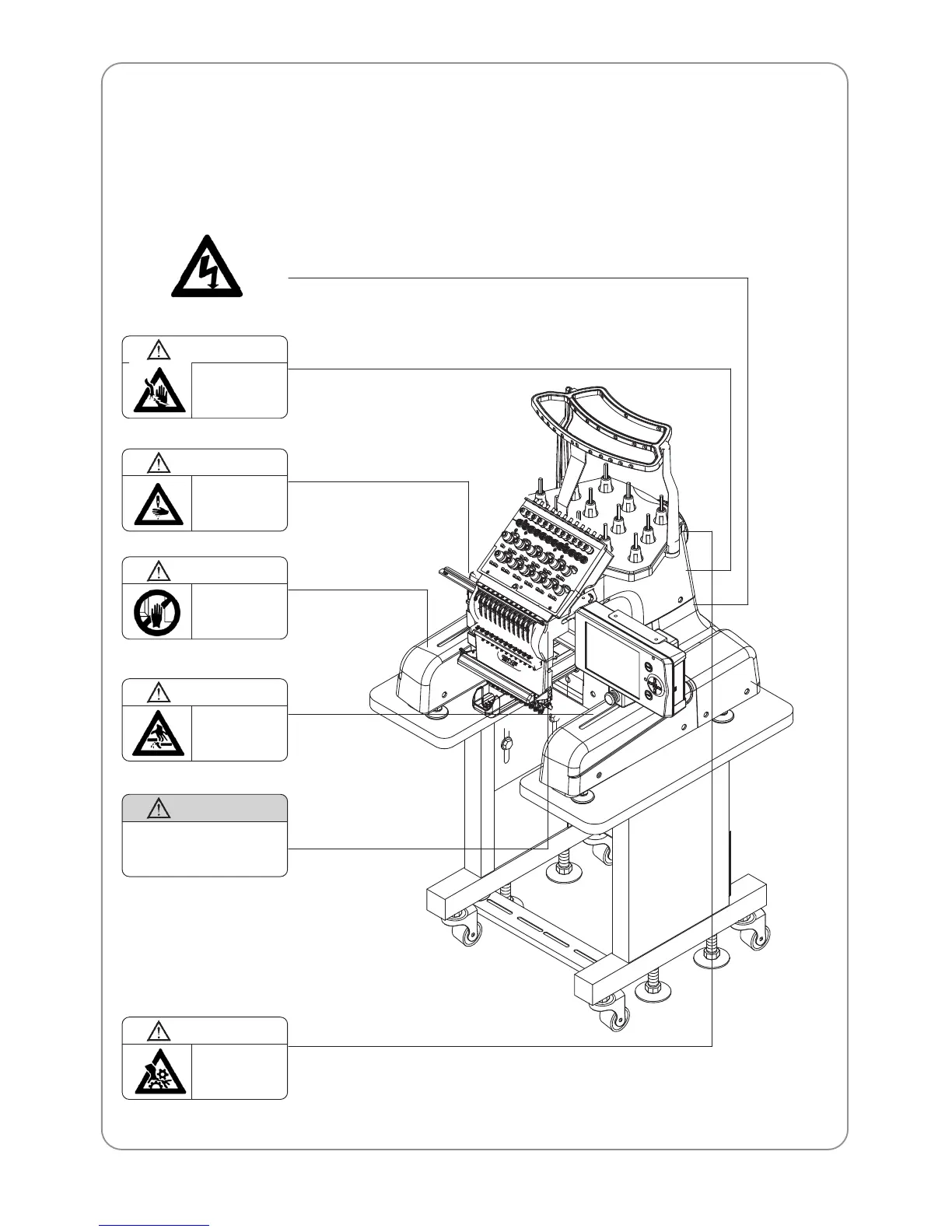

5.2) LOCATIONS OF SAFETY LABELS

WARNING

Fire or death may be caused by

high voltage electric shock.

Don’t open the cover except for

service man assigned by SWF.

When open the cover turn off

power and wait for 6 minutes.

Injury may be caused by moving

needle.

Ensure that the machine is in a

stop condition before changing,

threading or rethreading of

needies or changing of needles.

WARNING

Physical damage may be caused

by interposition.

While embroidery frame is running

according to the direction of

embroidery frame may be injured

your hands by gap between fixed

body and embroidery frame.

WARNING

WARNING

Physical injury may be caused

by crevice.

Don’t put your finger in a groove

on the table.

Injury may be caused by winding.

Be sure to turn off the power

before cleaning, lubricating,

adjusting or repairing.

WARNING

Physical damage may be caused by

winding.

Don’t put your hands near the

needle bar & take-up lever while

machine is running.

WARNING

Loading...

Loading...