33

8.1.12) Return to stop position in unexpected blackouts

Your SWF embroidery machine automatically returns to the previous position when the power comes back on

after an unexpected blackout, thereby not affecting the quality of the embroidery.

(See LCD Monitor User Manual)

8.2) NEEDLE-HOOK TIMING AND RELATED TIPS

8.2.1) Needle

– It is very important to select the right needle for the type of thread and fabric used.

– Inappropriate needles can cause bad embroidery, thread breaks, skipped stitches, etc.

– For normal embroidery, use a DB×K5 needle.

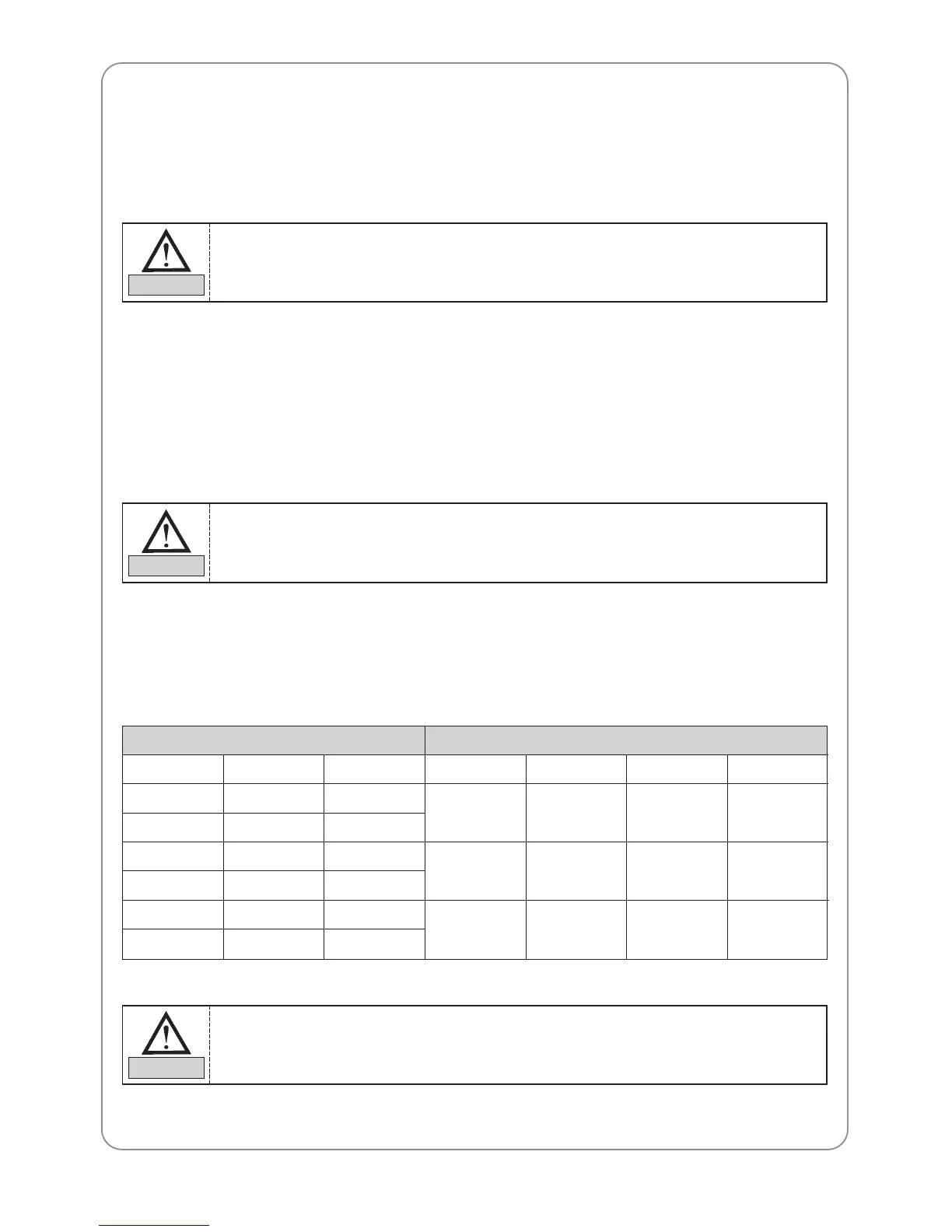

8.2.2) Relationship between needle and thread

– Inadequate selection of threads and needles can result in thread breaks, skipped stitches, as well as in bad-

quality embroidery.

– Refer to the following table for threads and needles used in normal embroidery.

US

0.25

0.27

0.29

0.32

0.34

0.36

Japan

9

10

11

12

13

14

Germany

65

70

75

80

85

90

Cotton #

70~80

50~60

36~40

Silk

100~120

80~100

60~70

Nylon

130~150

100~130

80~100

Rayon

70~100

100~130

130~150

Needle Size Thread Size

Make sure to turn OFF the main switch in unexpected blackouts until the power comes back

on.

CAUTION

DB

××

K5 needle has an eye twice larger than that of DB1 (used for normal stitching).

Use DB

××

K5 for normal embroidery.

CAUTION

Needle and thread most commonly used in embroidery

Thread : rayon yarn 120d/2.

Needle : DB

××

K5 #11

NOTE

Loading...

Loading...