35

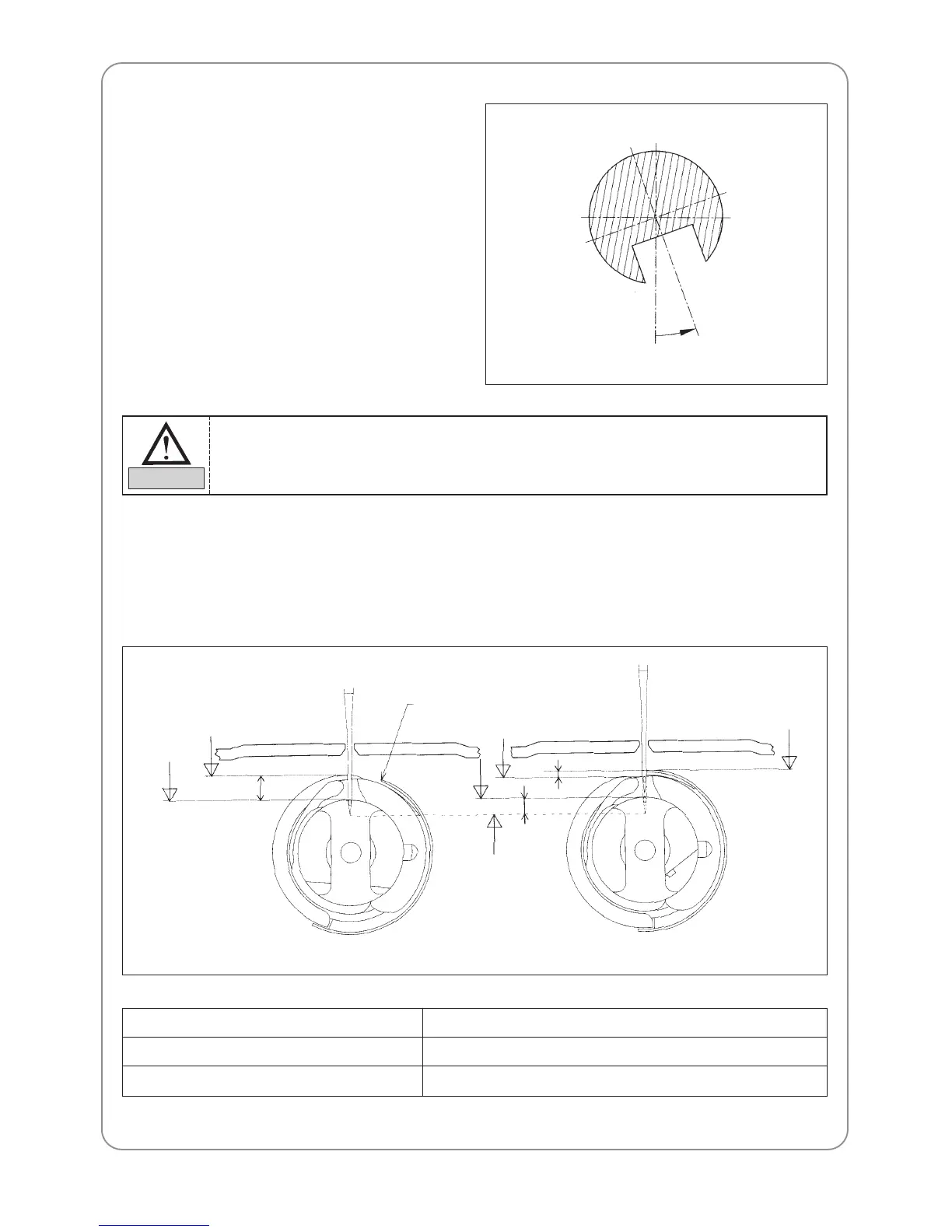

– When using special threads, such as artificial

silk, you might want to turn the groove of the

needle to the right in order to minimize the

thread breaks.

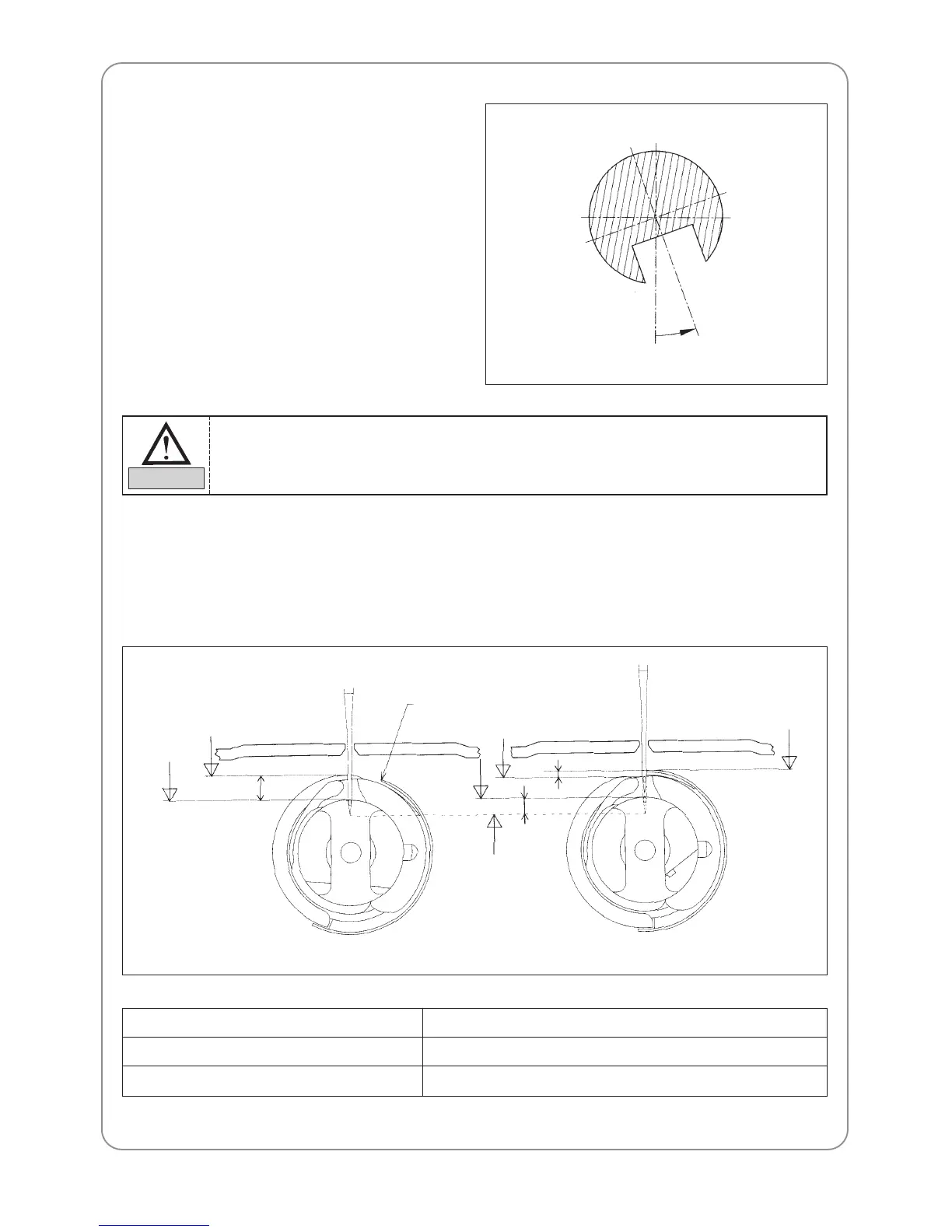

8.2.4) Relationship between needle and hook

– Adjusting timing between needle and hook

Default timing of the needle and the hook is set by the main shaft angle of 201°. Relationship between the

needle and the hook varies as below.

Top edge of the

needle hole

Top point of hook

circumference

a

Hook point

Top edge of the

needle hole

Needle tip

Lower dead stop

of the needle bar

Hook point

b

c

a. At lower dead stop of the needle bar 2.3~3.7 mm

b. At needle-hook timing 1.8~2.2 mm

c. At needle-hook timing 0.5~1.5 mm

If the needle is not inserted all the way to the top of the needle bar hole, timing of the machine

will go off, causing broken needles and thread breaks.

CAUTION

Loading...

Loading...