02. INSTALLATION OPTIONS AND CRITERIA FOR COMPLIANCE WITH LPS 1175: ISSUE 7

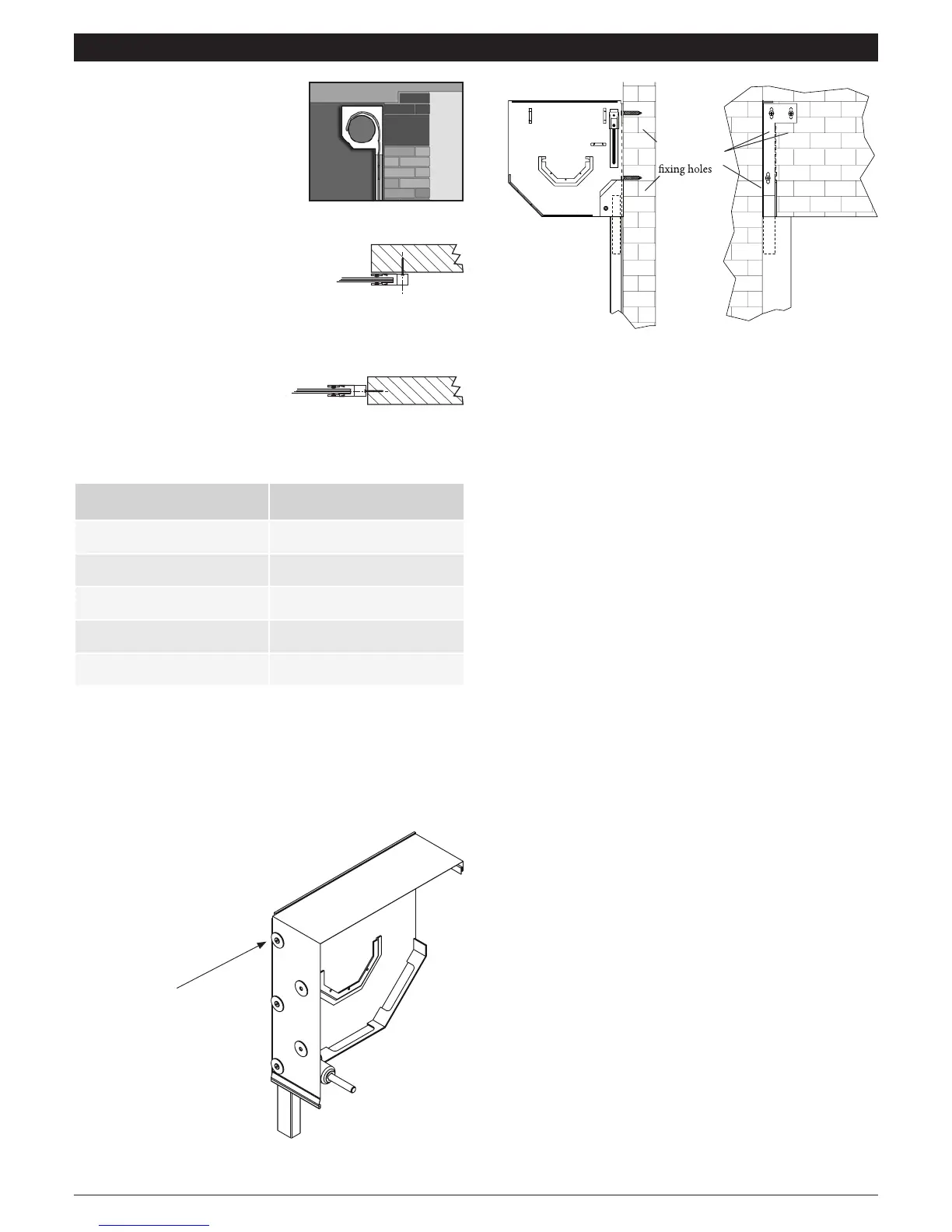

Internal installation only

The garage door must be installed

internally. If all of the end plate is not

fitted above the opening then a 90°

fascia must be fitted to the door.

Face fit

If the guide rails are face fitted they must

not protrude into the opening and they

must be 90mm.

Reveal fit

If the guide rails are reveal fitted

they must be 90mm guide rails

complete with steel reinforcement

plates to protect the base of the

guide rails.

Minimum number of fixings per guide rail

Proximity of holes to the end of the guide rails

The first and last holes at the ends of the guide rails must be

drilled 120mm from the ends of the guide rails.

When the head of the shutter is exposed

5no. penny washers riveted from external

side must be utilised to secure the

hood when the head of the shutter

is exposed within an opening.

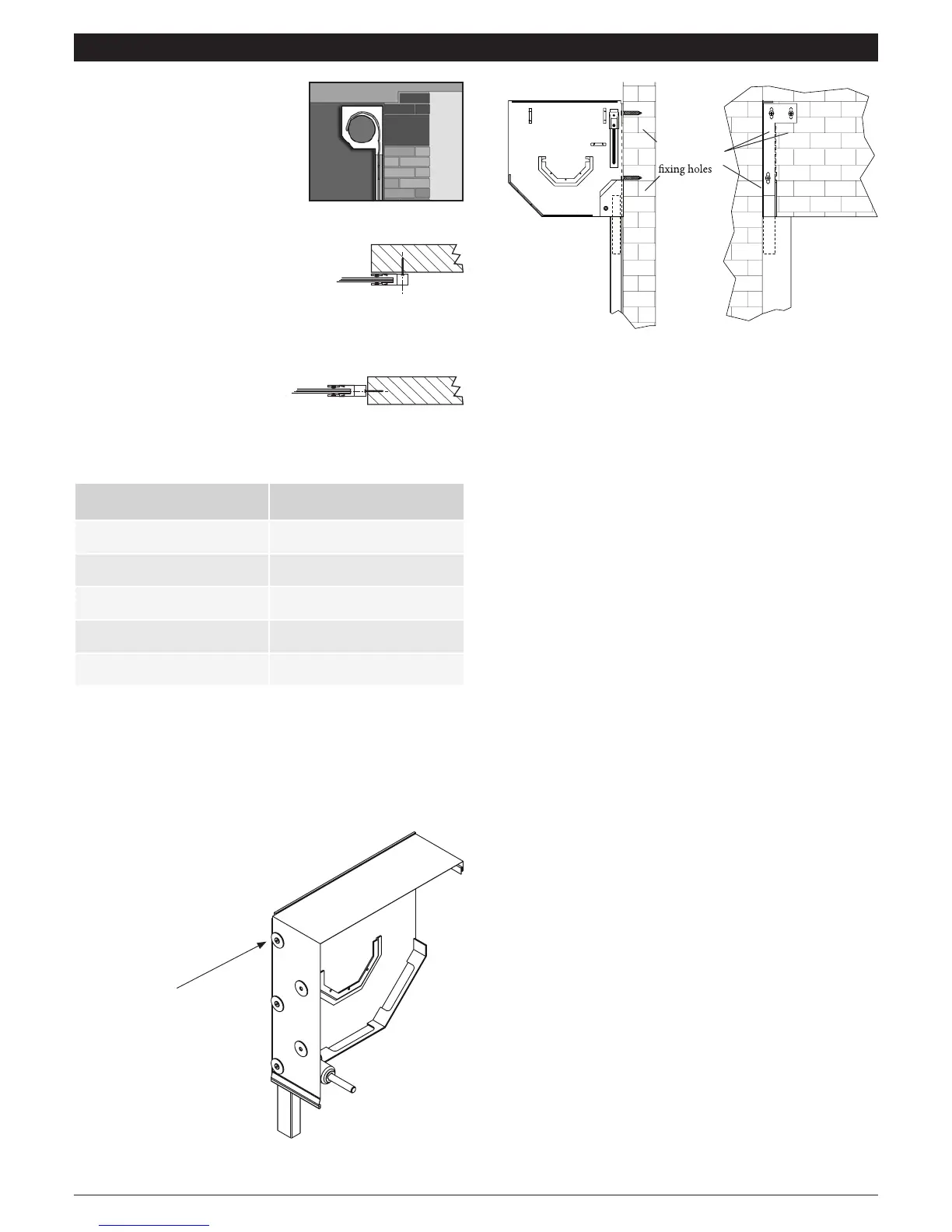

Minimum number of fixings per end plate

All three fixing holes in each end plate must be used

Minimum required fasteners

Brick / Blockwork

No. 12x2” screw with suitable plastic plug

Timber frame

No. 12x2” screw

Steel fixing (any of the following)

a. 5 x 25mmTec screws

b. No. 10x1” Pozi Pan head screws

c. M8 x10mm hex head or dome head bolts tapped in to the steel

work (minimum 5mm thick steel)

d. M8 bolts and nuts

All fixing heads must be spoiled for compliance with LPS 1175.

All switches, key switches and remote control equipment must be

installed on the inside of the garage for compliance with LPS 1175.

The label supplied, stating the manufacturer, the product, the security

rating and the certificate number must be attached to the door.

Please note: The validity of the LPCB certification is contingent

upon the roller garage door being installed in accordance with

the requirements of LPS 1175.

90mm

90mm

Loading...

Loading...