D400-06-00 2 I56-286-04R

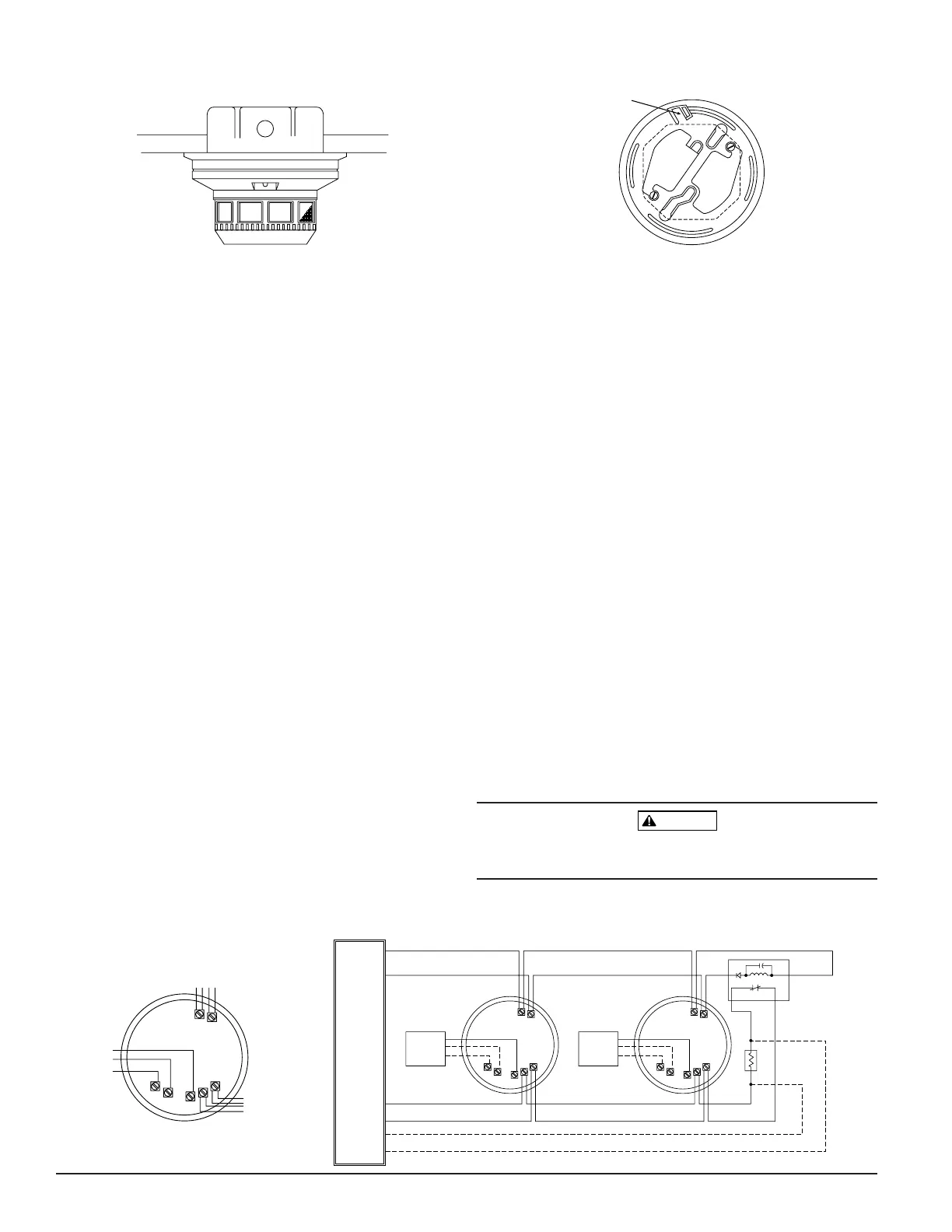

Mounting

Each 2412 and 2424 detector is supplied with a mounting

bracket kit that permits the detector to be mounted:

1. Directly to a 3

1

⁄2 inch or 4 inch octagonal, 1

1

⁄2 inch deep

electrical box, (see Figure 1) or

2. To a 4 inch square electrical box by using a plaster ring

with the supplied mounting bracket kit.

Installation Wiring Guidelines

NOTE: Refer to releasing device manufacturer’s installa-

tion instruction for proper connections.

All wiring must be installed in compliance with the

National Electrical Code and all applicable local codes and

any special requirements of the authority having jurisdic-

tion, using the proper wire size. The conductors used to

connect smoke detectors to control panels and accessory

devices should be color-coded to reduce the likelihood of

wiring errors. Improper connections can prevent a system

from responding properly in the event of a fire.

For signal wiring (the wiring between interconnected

detectors), it is recommended that the wire be no smaller

than AWG 18. However, the screws and clamping plate, in

the base, can accommodate wire sizes up to AWG 12. The

use of twisted pair wiring for the power (+ and –) loop is

recommended to minimize the effects of electrical interfer-

ence.

Smoke detectors and alarm system control panels have

specifications for allowable loop resistance. Consult the

control panel manufacturer’s specifications for the total

loop resistance allowed for the particular model control

panel being used before wiring the detector loops.

NOTE: For system supervision – for terminals 1, 2, 7, and

8, do not use looped wire under terminals. Break

wire run to provide system supervision of connec-

tions.

NOTE: Contacts are shown in stand-by mode and will

transfer in alarm condition.

Wire connections are made by stripping about

3

⁄8 inch of

insulation from the end of the wire, sliding the bare end of

the wire under the clamping plate, and tightening the

clamping plate screw.

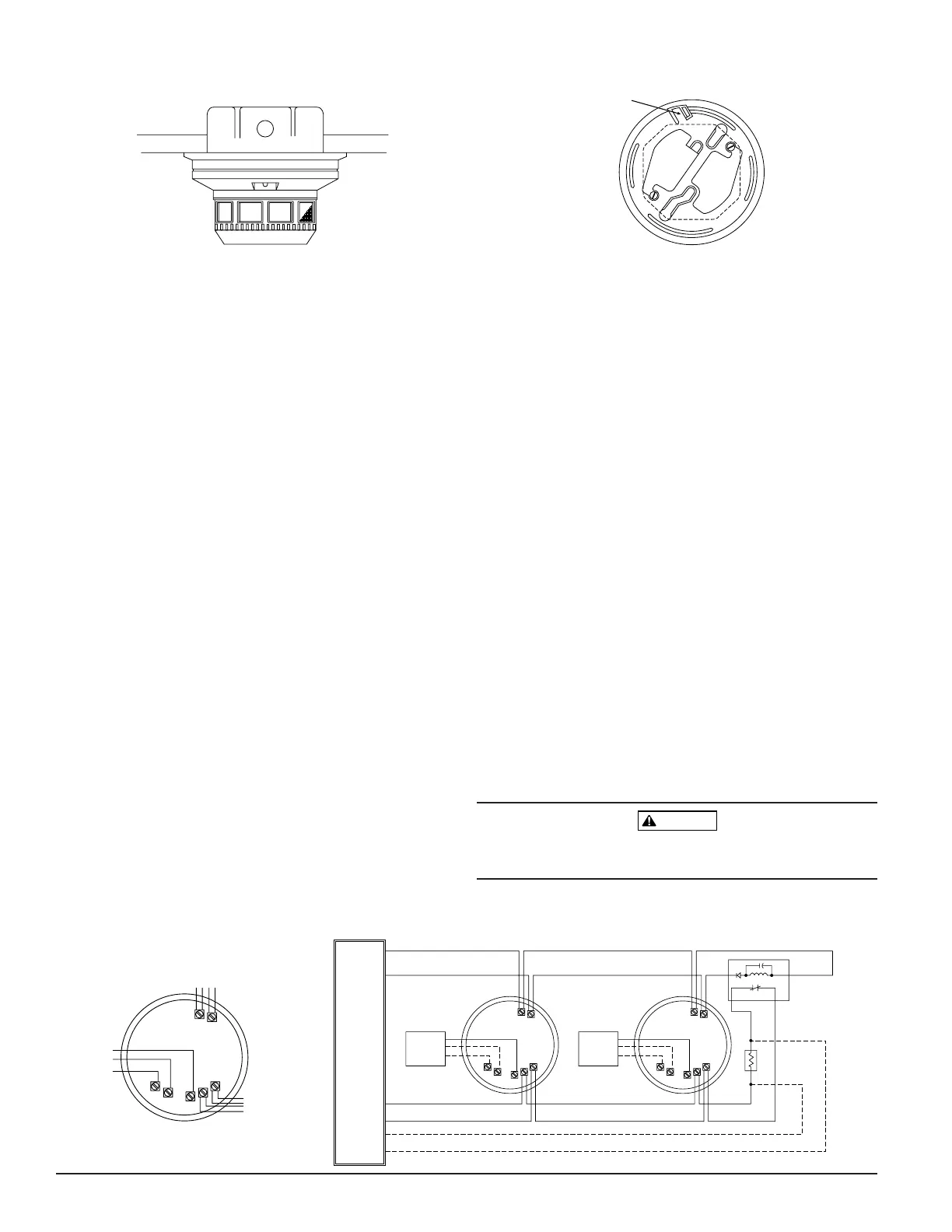

Tamper-resistance Feature

This detector includes a tamper-resistant feature that pre-

vents removal of the detector without the use of a tool. To

make the detector tamper-resistant, break off the smaller

tab at the scribed line on the Tamper Resistant Tab, on the

detector mounting bracket (see Figure 2), then install the

detector. To remove the detector from the bracket once it

has been made tamper-resistant, use a small screwdriver to

depress the tamper-resistant tab located in the slot on the

mounting bracket and turn the detector counterclockwise

for removal.

Installation

Remove power from initiating-device circuits before

installing detectors.

Loading...

Loading...