I56-2081-013 © System Sensor 2009DB200-01-01

5

DEUTSCH

ESPAÑOL

ENGLISH ITALIANO

FRANÇAIS

Test Failure Checks

If the detector fails either the sensitivity or functional test, several

steps should be taken before returning the unit to determine if it is

faulty, or simply needs to be re-adjusted. These steps include:

1. Verify all wiring connections and appropriate power is applied to the

detector.

2. Verify that the optical line of sight is free from obstructions and

reflective objects.

It is imperative that at least 90% of the received light is from the

reflector alone, otherwise sensitivity cannot be assured.

3. Apply the maintenance procedure in this manual. Repeat the test

procedure. If the detector still fails the test procedure proceed with

step 4.

4. Repeat the alignment procedure in this manual. If the alignment

procedure is successful repeat the test procedure. If the detector

still fails the test it should be returned for repair.

6500 BEAM DETECTOR: SET-UP PROCEDURE SUMMARY

Beam Alignment – ensure power is on

Course Alignment

Carry out using target eyepiece

Adjust using horizontal and vertical thumb screws

Fine Adjustment

Initiate using

Alignment Switch

Continue adjustment using horizontal and vertical thumb screws

When the adjustment is complete press the

Alignment Switch

Sensitivity Setting

Select using

Sensitivity Switch

Final Gain Adjustment – ensure front cover is fitted

Initiate using the

Reset Switch

Completed when the green LED blinks

Final Verification

Use obscuration filters or reflector test card to initiate

Fire

and

Fault

signals

MAINTENANCE

Note: Before cleaning the detector, notify the proper authorities that

the smoke detector system is undergoing maintenance, and therefore

the system will be temporarily out of service. Disable the zone or

system undergoing maintenance to prevent unwanted alarms.

1. Carefully clean the outer housing lens face. A damp soft cloth with

a mild soap may be used. Avoid products with solvents or

ammonia.

2. Carefully clean the reflector. A damp soft cloth with a mild soap

may be used. Avoid products with solvents or ammonia.

Functional Testing

For periodic maintenance functional testing, the detector can either be

tested using the Calibrated Test Filter method, by using the local test

switch on the transmitter receiver unit or remotely using the Remote

Test Station.

The Remote Test Station, 6500RTS-KEY, can be used with the 6500R

beam smoke detector. Follow the Installation and Maintenance

instructions included with the 6500RTS-KEY for proper use.

The 6500RS is equipped with an integral sensitivity test feature that

consists of a calibrated test filter attached to a servomotor inside the

detector optics. When a test is initiated using the remote test station or

local test switch the test filter is moved in the pathway of the light

beam. If the correct level of signal reduction is received the detector

will enter alarm. If the proper level of signal reduction was not

achieved, indicating that the sensitivity of the detector is out of

tolerance, the detector will enter the fault condition.

Note: This test should satisfy most local periodic maintenance and

testing requirements.

If the detector fails this test, refer to the Test Failure Checks described

above.

PAINTING

The outer aesthetic ring may be painted using enamel or acrylic paints

either by brush or spray.

Note: Never paint the flat lens surface of the outer housing.

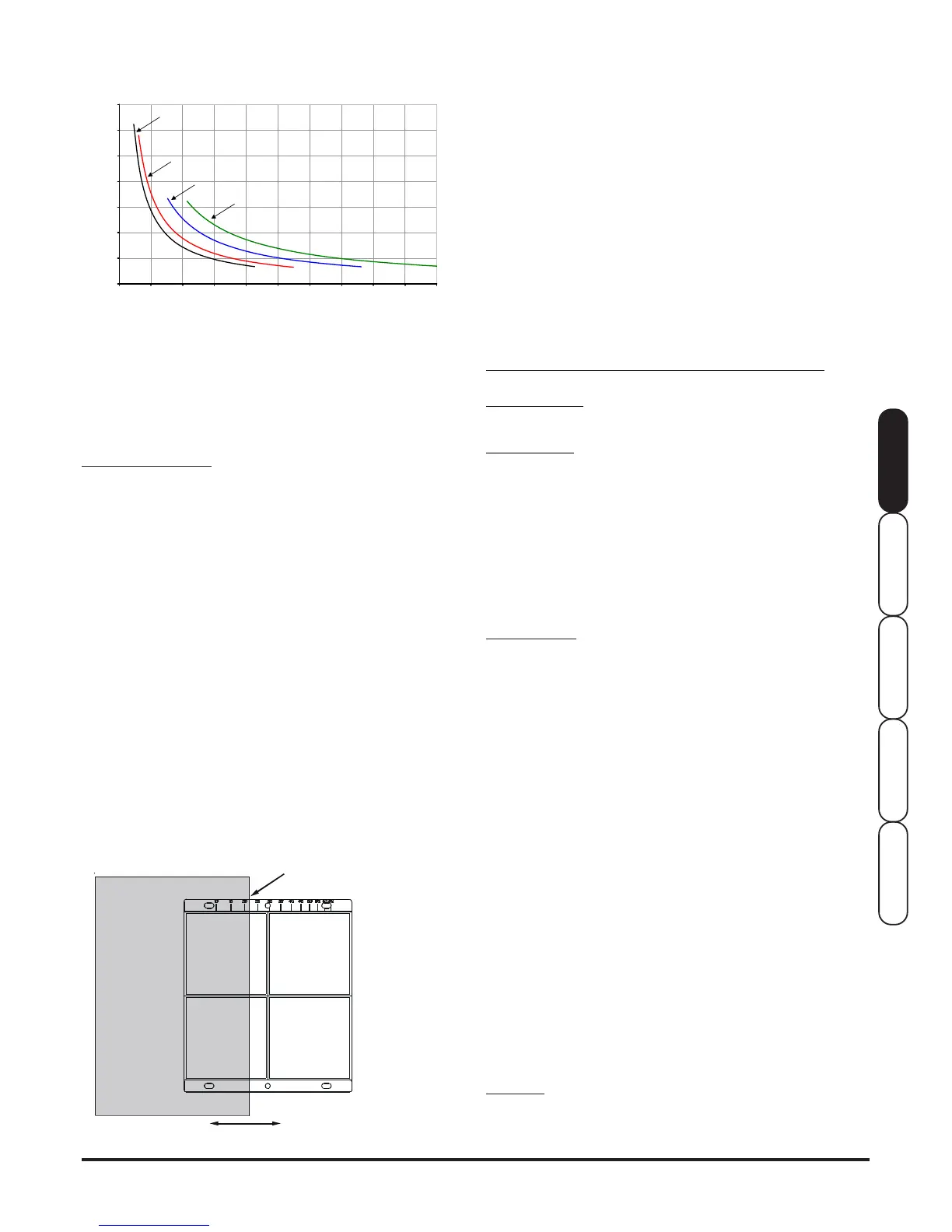

In addition to the four standard sensitivity selections the detector has

two Acclimate settings. When either of these settings is chosen the

detector will automatically adjust its sensitivity using advanced

software algorithms to select the optimum sensitivity for the

environment. The sensitivity will be continuously adjusted within the

ranges specified in graph 1.

Total obscuration can be converted to percent per metre assuming

uniform smoke density for the entire length of the beam. Graph 1

converts total obscuration to percent per metre for all acceptable

sensitivity settings.

SENSITIVITY TESTING

NOTES:

1. Before testing, notify the proper authorities that the smoke detector

system is undergoing maintenance, and therefore the system will

be temporarily out of service. Disable the zone or system

undergoing maintenance to prevent unwanted alarms.

2. Before testing the detector, check for the presence of the flashing

green LED at the receiver, making sure not to disturb or block the

beam. If it does not flash and the detector is not in fault or alarm,

power has been lost to the detector.

Detectors must be tested after installation and following periodic

maintenance. The sensitivity of the 6500R may be tested as follows:

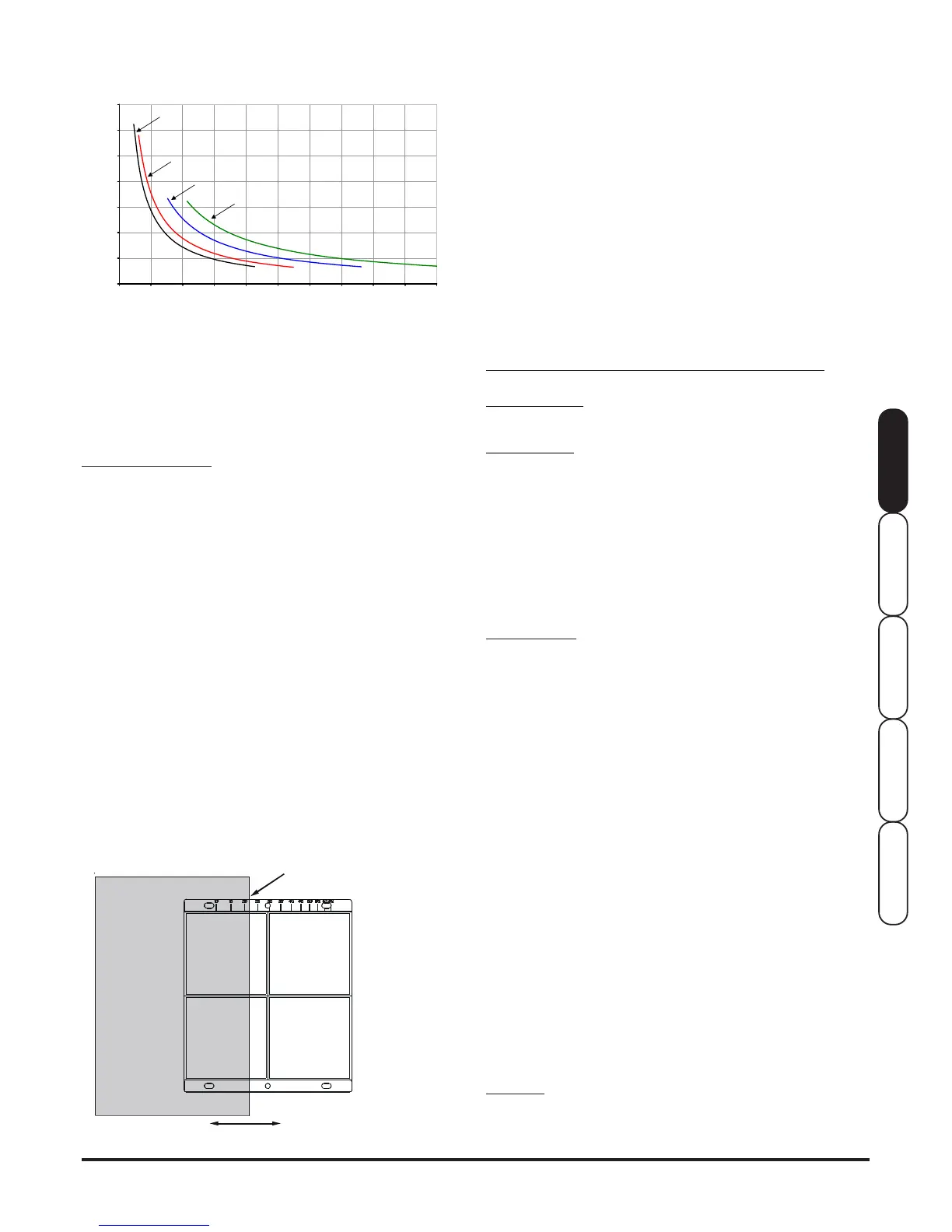

Calibrated Test Filter Method

The sensitivity of the detector can be tested using an opaque material

( such as this manual ) to cover the reflector by an amount indicated

by the graduated scale on the reflector, see Figure 10.

1. Verify the sensitivity setting of the detector in % obscuration. See

the Sensitivity Selection section of this manual for sensitivity

determination if sensitivity is unknown.

2. Place the blocking material over the reflector, lining it up with the

graduated marks that are 10 less than the detector setting in %

obscuration. The detector should not alarm or fault. Keep the

material in place for a minimum of 1 minute.

3. Place the blocking material over the reflector lining it up with the

graduated marks that are 10 more than the detector setting in %

obscuration. The detector should enter alarm within 1 minute.

4. The detector can be reset with the reset switch on the detector

unit or remote reset.

Figure 10. Reflector Test Card Procedure

LINE UP EDGE OF BLOCKING MATERIAL

WITH APPROPRIATE OBSCURATION LEVEL

MOVE BLOCKING MATERIAL TO

DESIRED AMOUNT OF OBSCURATION

GRAPH 1: SENSITIVITY (%M vs DISTANCE)

(Assuming Uniform Smoke Distribution)

0

1

2

3

4

5

6

7

0 102030405060708090100

Distance (Metres)

Obscuration (%/Metre)

Level 1

Level 2

Level 3

Level 4

Loading...

Loading...