I56-2081-013 © System Sensor 2009DB200-01-01

4

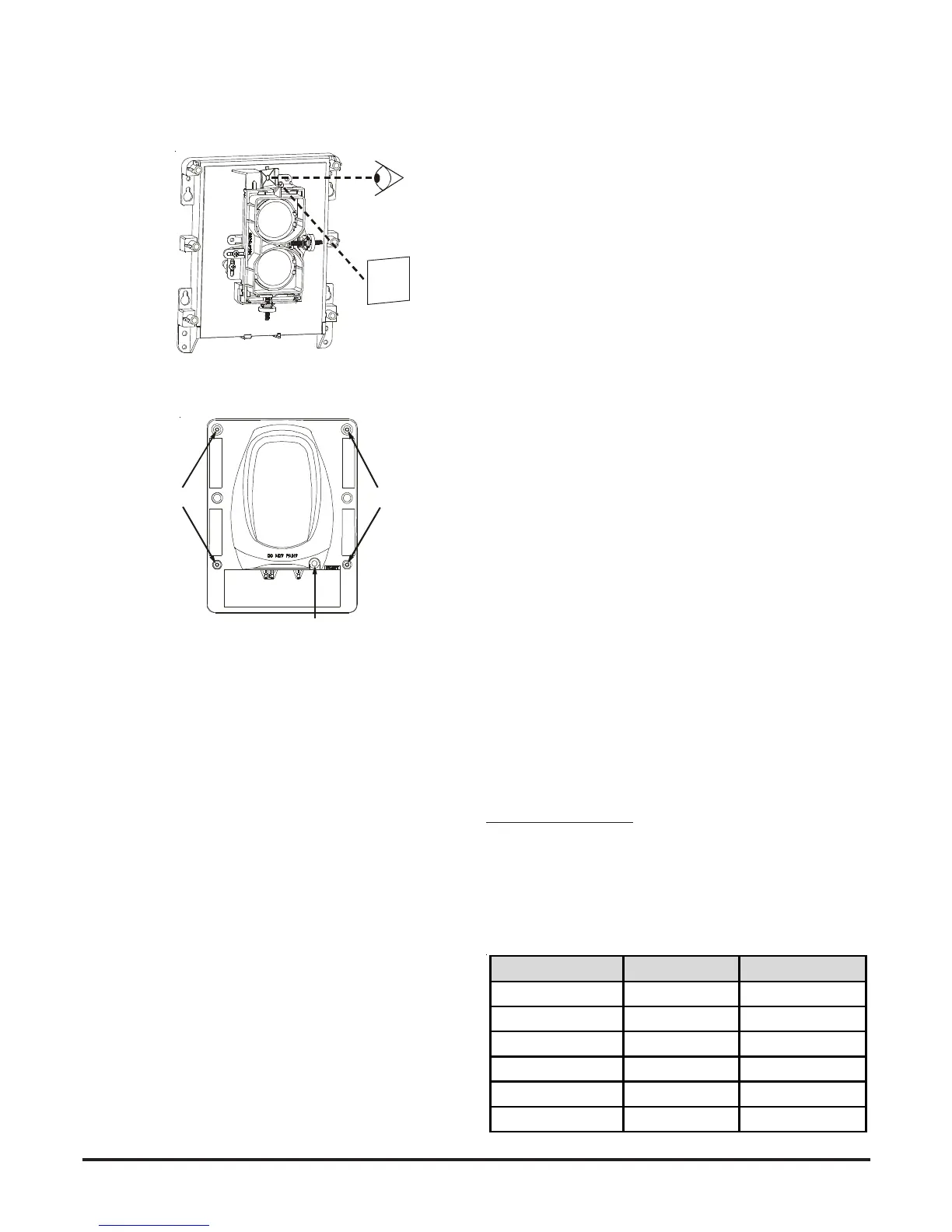

Figure 8: Coarse Alignment Procedure

REFLECTOR

SCREW

LOCATIONS

Note that the alignment gun site does not give an accurate alignment.

It is sufficient only as a starting point for the next step. On completion

of the fine adjustment procedure, the alignment gun site may not

appear to be centred on the reflector.

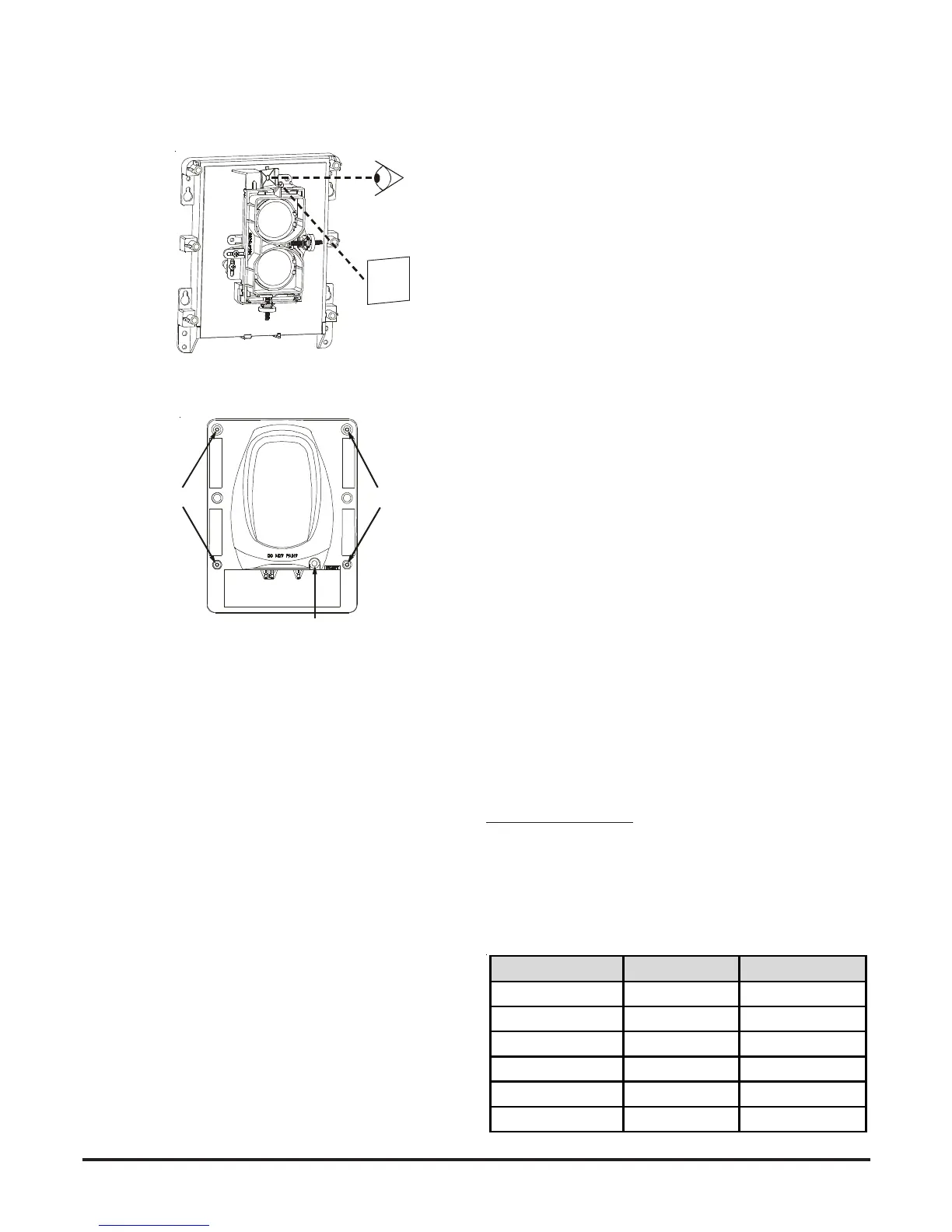

SCREW

LOCATIONS

Figure 9: Housing Screw Locations

EYE

Step 2. Fine Adjustment

See figures 6 to 8.

1. Ensure that no objects are in the line of sight between the detector

and the reflector.

2. Depress the Alignment switch once. Both the digital display and

the yellow LED should turn on indicating that alignment mode has

been entered. The display should begin reading “- -” signifying an

electronic gain adjustment. After a few moments the display will

indicate a numeric value near 20.

Note: If the display reads “Lo” then the detector is not receiving

enough light from the reflector. Go back and repeat the course

alignment step and verify that the proper number of reflectors is

used for the installed distance. The display will continue to read

“Lo” until the detector receives enough light from the reflector to

continue with the fine adjustment step.

Note: In alignment mode (indicated by the yellow LED and the

numeric display) the sensitivity select and test switches are

disabled.

3. Once the display shows a number, begin adjusting the horizontal

and vertical alignment knobs one at a time to increase signal level

on the display. Continue adjusting each axis one at a time going

back and forth between them until a peak value is indicated. If a

value of 90 is achieved, the detector will reduce its electronic gain.

This will be indicated by a “- -” reading on the display. When this

happens halt any further adjustment until the display again reads a

numeric value. This process may occur more than once during

the fine adjustment step.

4. Once satisfied that it is not possible to achieve a higher reading on

the display depress the alignment switch to complete the fine

adjustment step. The digital display readout will turn “OFF” and the

yellow LED will remain “ON”.

Note: It may not be possible to achieve a figure close to 90 on the

display during the last adjustment iteration. Each time the figure 90

is reached the gain is reduced, making it more difficult to achieve

high values. Any number is acceptable, provided it is the highest

figure that can be achieved after the final gain adjustment.

At this time it is sensible to set the sensitivity of the detector using the

sensitivity switch and digital display. See SENSITIVITY SELECTION

for further details.

Step 3. Final Gain Adjustment

See figure 9.

In this step, the detector electronically adjusts its internal gain one final

time. It is necessary to complete this step with the outer housing

installed since the housing will change the amount of light received

from the reflector.

1. Install the outer housing of the detector. The housing is installed by

tightening the four captive screws, one in each corner of the

housing.

Note: The housing contains a gasket seal that protects the

detector circuitry from corrosion and moisture. To ensure that this

gasket performs correctly, it is necessary to tighten all four of the

screws holding the outer housing in place evenly.

2. Remove the protective film from the front surface of the outer

housing. Note that the outer housing may require cleaning if any

residue remains. Use only a soft, damp cloth; do not use any

solvents.

3. To initiate the final electronic gain adjustment, the reset switch

must be depressed using a small screwdriver or similar tool. Once

depressed the yellow LED will begin to blink. On completion, the

yellow LED will stop blinking and the green LED will begin blinking,

indicating that the gain adjustment was successful.

Note: Use caution not to block the line of sight between the

detector and reflector in this step.

4. Install the outer aesthetic ring by snapping it onto the outer

housing.

Note: If the outer aesthetic ring has been painted ensure that the

paint is completely dry before proceeding with this step.

Step 4. Final Verification

This step is required to insure the detector has been setup correctly

and will detect smoke at the proper sensitivity level.

1. With the detector functioning (dependant on the operation of the

control panel, this may be indicated by the green LED blinking),

completely block the reflector with a non-reflective opaque

material, for example this manual. After about 30 seconds, the

detector should enter either the fault or alarm condition. If the

detector does not enter the fault or alarm condition, there is a

problem with the installation.

2. Complete a sensitivity test of the detector as described in

SENSITIVITY TESTING below.

SENSITIVITY SELECTION

The sensitivity of the detector can be set only when the housing is

removed and the detector is not in the fine adjustment step of the

alignment mode. To enter the selection mode, press the sensitivity

button once (see figure 6). The digital display will illuminate and read

the current sensitivity setting in percent obscuration. Press the

sensitivity button again to rotate to the next setting. Once the required

setting is achieved (See table 1), the detector will exit the sensitivity

selection mode if no further switch presses occur.

RESET SWITCH

Sensitivity Setting % Obscuration Display Reading

Level 1 25 25

Level 2 30 30

Level 3 40 40

Level 4 50 50

Acclimate Level 1 30 to 50 A1

Acclimate Level 2 40 to 50 A2

Table 1: Sensitivity Settings

Loading...

Loading...