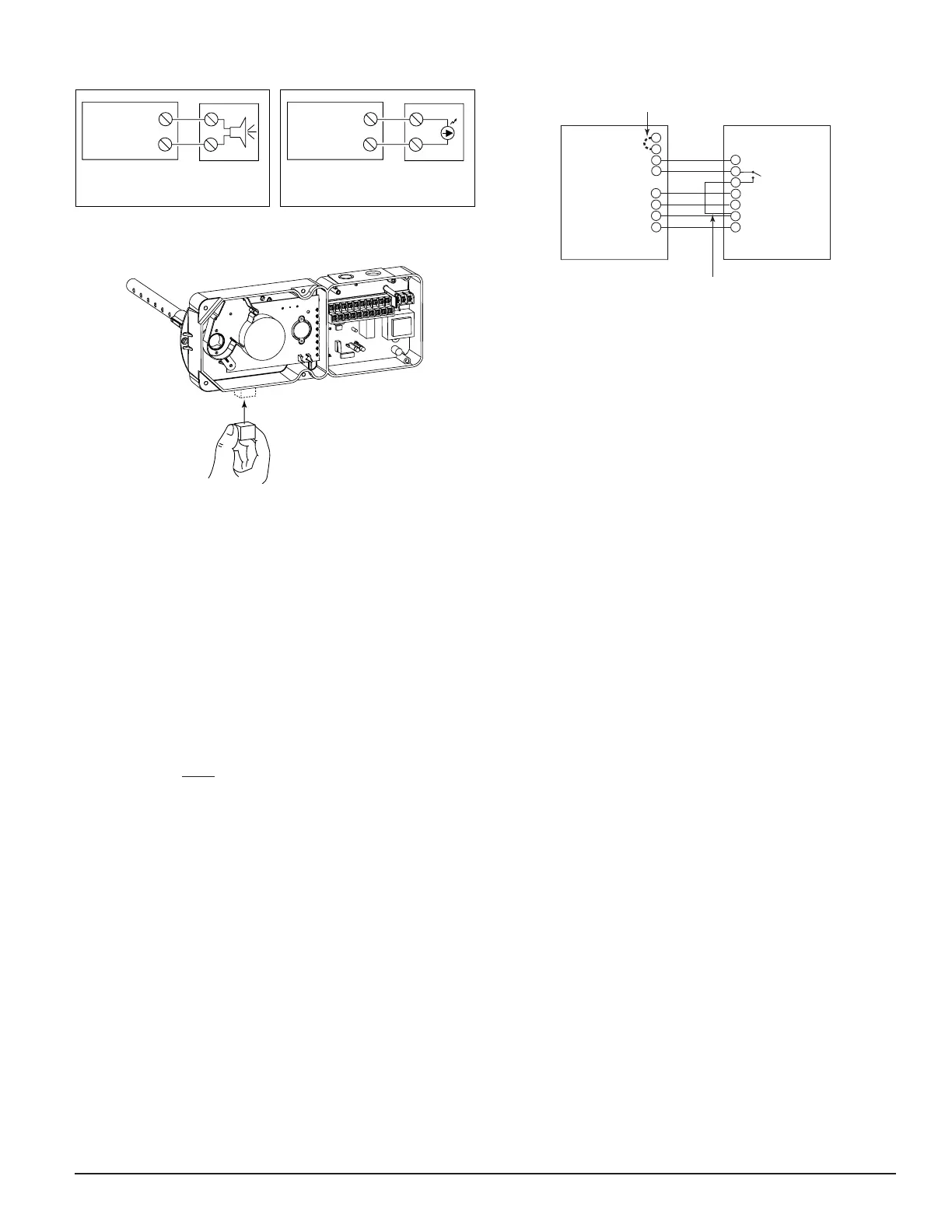

Figure 13. Testing detector alarm:

Cover

Tamper — If the cover is removed or not properly secured

for a period longer than 20 minutes, a trouble

signal is generated to indicate the cover is missing.

[6.2.2] Alarm Tests

[6.2.2.1] M02-04-00 Magnet Test

1. Place the painted surface of the magnet onto the TEST

locator on the bottom of the housing (Figure 13).

2. The red alarm LED on the detector should latch on, as

should any accessories (i.e. RA400Z, RTS451). Verify

system control panel alarm status and control panel exe-

cution of all intended auxiliary functions (i.e. fan shut-

down, damper control, etc.).

3. The detector must be reset by system control panel, front

cover reset button, or remote accessory.

[6.2.2.2] RTS451/RTS451KEY Remote Test Station

The RTS451/RTS451KEY Remote Test Station facilitates test

of the alarm capability of the duct smoke detector as indi-

cated in the RTS451/RTS451KEY manual. The DH100ACD-

CLP duct smoke detector can be reset by the

RTS451/RTS451KEY. If a system control panel is used, the

panel itself may also require testing.

To install the RTS451/RTS451KEY, connect the device as

shown in Figure 9; wire runs must be limited to 25 ohms

or less per interconnecting wire.

Please note that the magnetic coil supplied with the

RTS451 and RTS451KEY is not required when these acces-

sories are used with the DH100 Series detectors. The func-

tionality of the magnetic coil has been designed into the cir-

cuitry of the new Innovair™ duct smoke detectors.

D200-14-00 7 I56-0084-00

[6.2.2.3] SSK451 Multi-Signaling Accessory

The System Sensor SSK451 Multi-Signaling accessory com-

bines a sounder feature with a key activated test and reset

function. Green, amber and red LEDs provide a visual indica-

tion of power, trouble, and alarm respectively. An optional

strobe (PS24LO) with a smoke lens can be added to conform

to the codes of certain jurisdictions.

To install the SSK451, connect the device as shown in figure

12.

[6.2.3] Sensitivity Tests

[6.2.3.1] MOD400 or MOD400R Test

After verification of alarm capability, use the MOD400R test

module with a voltmeter to check detector sensitivity as

indicated in the test module’s manual. The housing cover

must be removed to perform this test.

If test module readings indicate that the detector head is

outside of the acceptable range that is printed on the label

of the detector, the detector chamber requires cleaning per

Section [7] of this manual.

[7] Detector Cleaning Procedures

Notify the proper authorities that the smoke detector sys-

tem is undergoing maintenance, and that the system will

temporarily be out of service. Disable the zone or system

undergoing maintenance to prevent unwanted alarms and

possible dispatch of the fire department.

[7.1] Air Filters

1. Turn off power to the system.

2. Remove and inspect sampling tube filters.

3. If filters are heavily coated with dirt, replace them with

new filters. If they are not heavily coated, use a vacuum

cleaner or compressed air nozzle to remove dust, then

reinstall the filters.

[7.2] Photo Detector Board

1. Remove the screen by gently grasping on each side and

pulling straight off.

2. Lift the photo chamber in the same fashion. Vacuum the

screen and cover. Use clean, compressed air to loosen

and blow out any remaining debris. Replacement

screens (S08-39-01) are available.

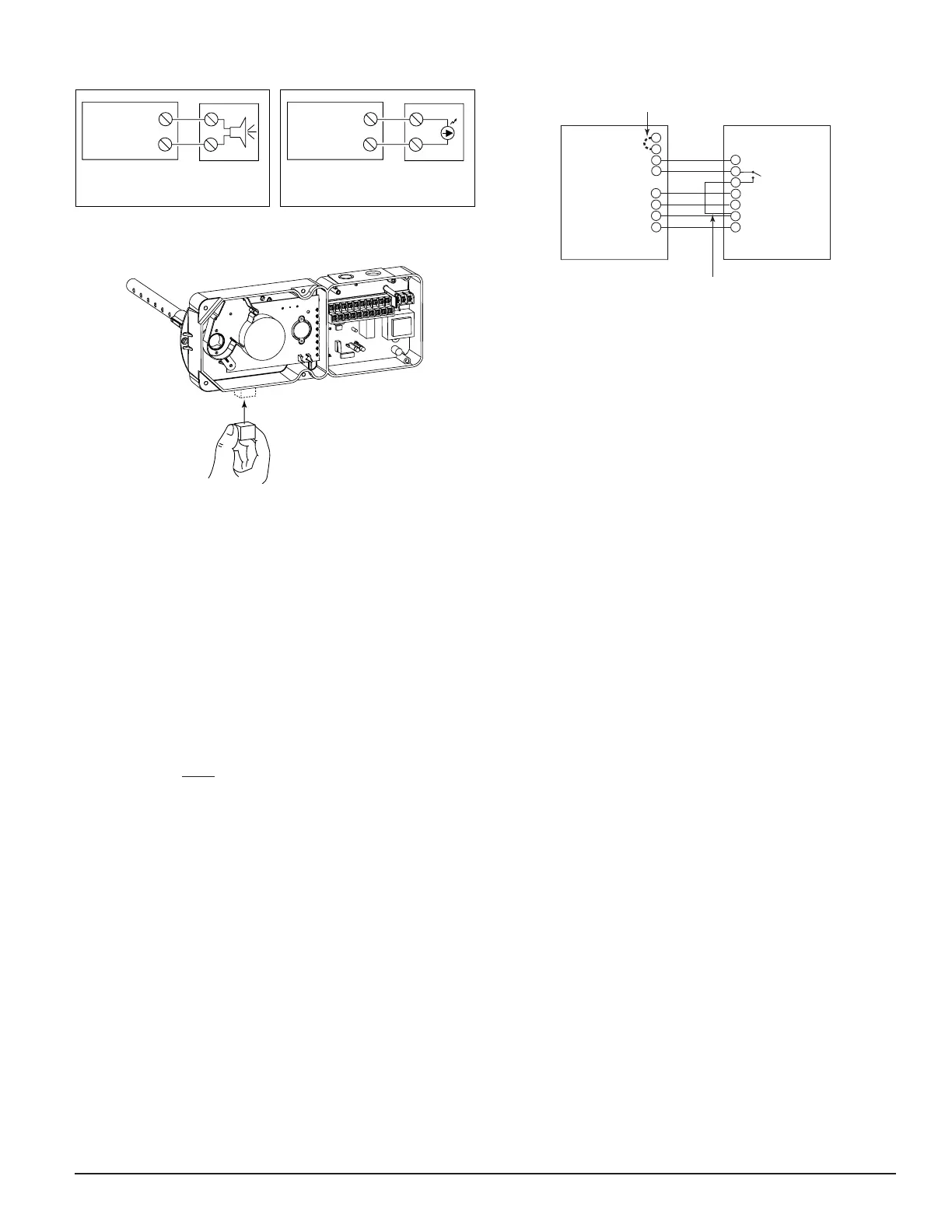

Figure 11. Wiring diagrams for optional accessories:

A78-2354-11

15 ALARM SIGNAL

3

14

2 RESET

11 TEST

20 AUX. POWER (-)

19 AUX. POWER (+)

SSK451

FIELD INSTALLED

JUMPER FOR

TEMPORAL PATTERN

SUPERVISORY

CONTACT

NO

FIELD INSTALLED

JUMPER

DH100ACDC

COMMON 3

TEMPORAL SELECT 2

ALARM SIGNAL 1

SUPERVISORY SIGNAL 4

RESET 7

TEST 8

POWER (-) 6

POWER (+) 5

Figure 12. Wiring diagram for DH100ACDCLP to

SSK451

Loading...

Loading...