CNC-210A Series H6681 User manual

Page

9

of 20

έᚊཝҋજѣࢨΦ

TAILY AUTOMATION CO.,LTD.

7. CONFIGURATION SETTING

CNC-210A is a multi-purpose design, to meet various requirements; additional settings are

configured to provide flexibility for additional applications.

In the READY mode, press the following keys combination as section [7.1. ~7.10], the DATA

DISPLAY will show corresponding setting value. If no change is necessary, press the key get

back to READY mode. Or press key to get into change mode, then the parameter can be

changed by pressing the numerical key followed by the key.

7.1. Winding mode selection

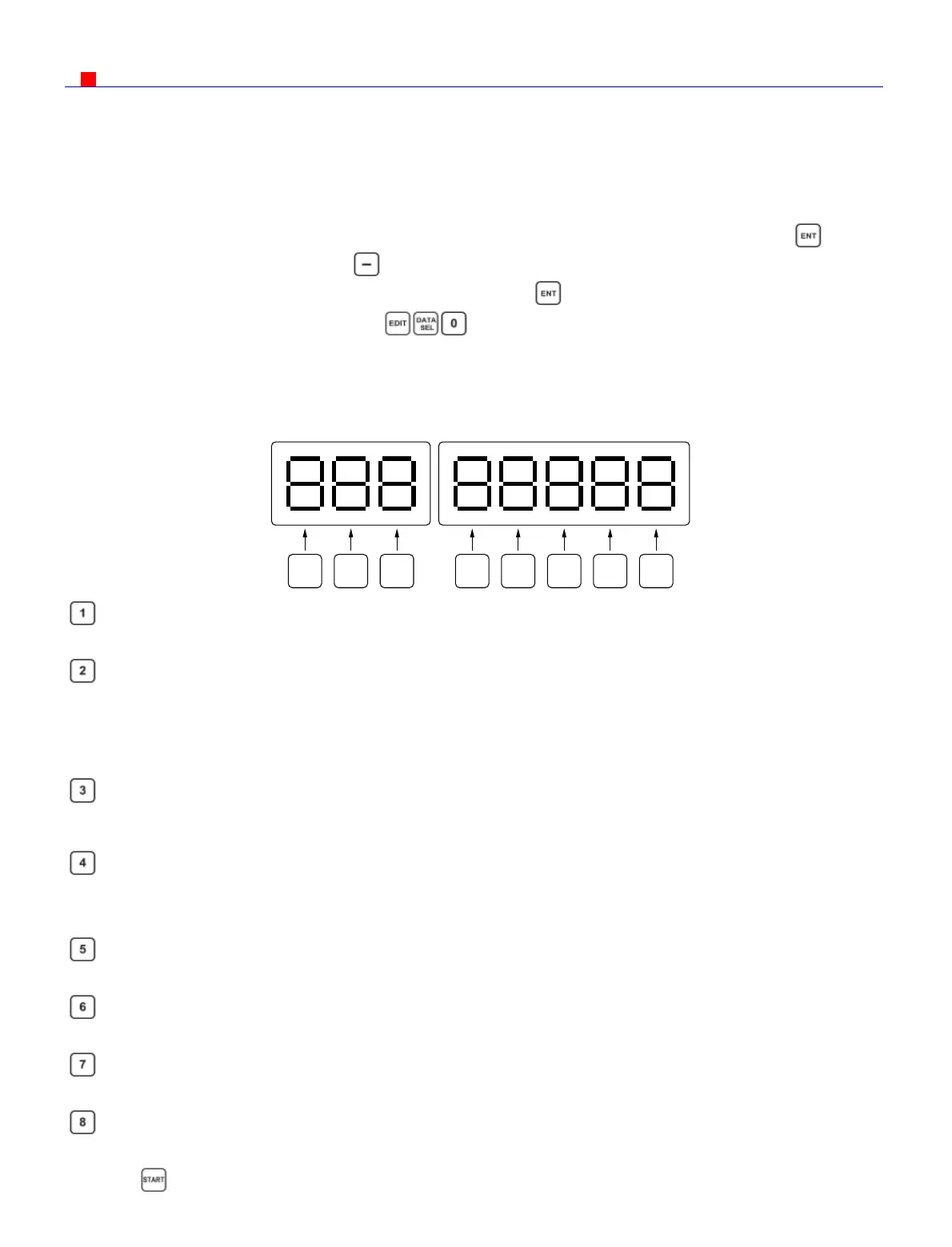

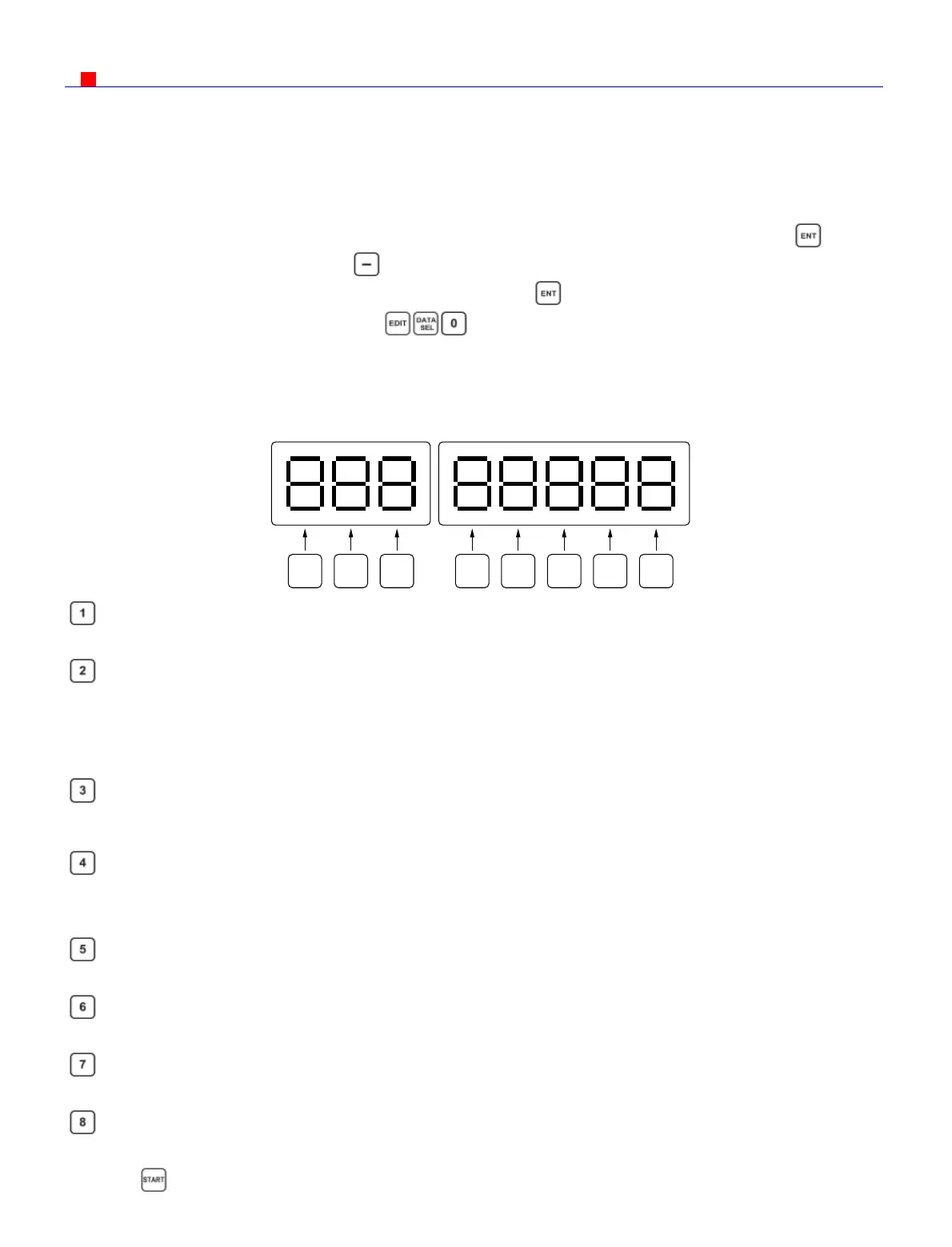

In this function the STEP display and the DATA display will shows eight digits, representing eight

winding mode selections respectively.

Press numerical keys as below to set each digit.

12345678

Moving speed

:

The guiding traverse moving speed.

0 represents high speed; 1 represents low speed.

Moving increment

:

The travel increment of the guiding traverse.

1 represents 0.01mm (4 mm per revolution).

2 represent 0.02mm (8 mm per revolution).

4 represent 0.04mm(16 mm per revolution.

Counting mode

:

Select the counting mode of the winding spindle shaft.

0 represents with zero point and using absolute counting mode.

1 represents without zero point and using relative counting mode.

Edge slow

:

Slow down the winding speed before the guiding traverse reach to the two

edges of the width.

0 represents not slow down; 1 represents to slow down.

Braking mode

:

Select the braking mode of the winding spindle.

0 represents single brake mode; 1 represents double brake mode.

Counting unit

:

Select 0.1 or 1 turns as your count unit.

0 represents 0.1(0.0 to 9999.9 turns); 1 represents 1(0 to 99999 turns).

Guiding traverse unit

:

Select the basic unit of guiding traverse.

0 represents mm; 1 represents inch (must using lead screw in imperial).

Operation mode

:

Select operation mode for the START switch.

0 represents Single click mode; 1 represents Double click mode.

The key on the front panel always as the Double click mode.

Loading...

Loading...