CNC-210A Series H6681 User manual

Page

15

of 20

έᚊཝҋજѣࢨΦ

TAILY AUTOMATION CO.,LTD.

9. ADJUSTMENT

9.1. Adjustments for CNC-210AS

CL

:

Output current limit.

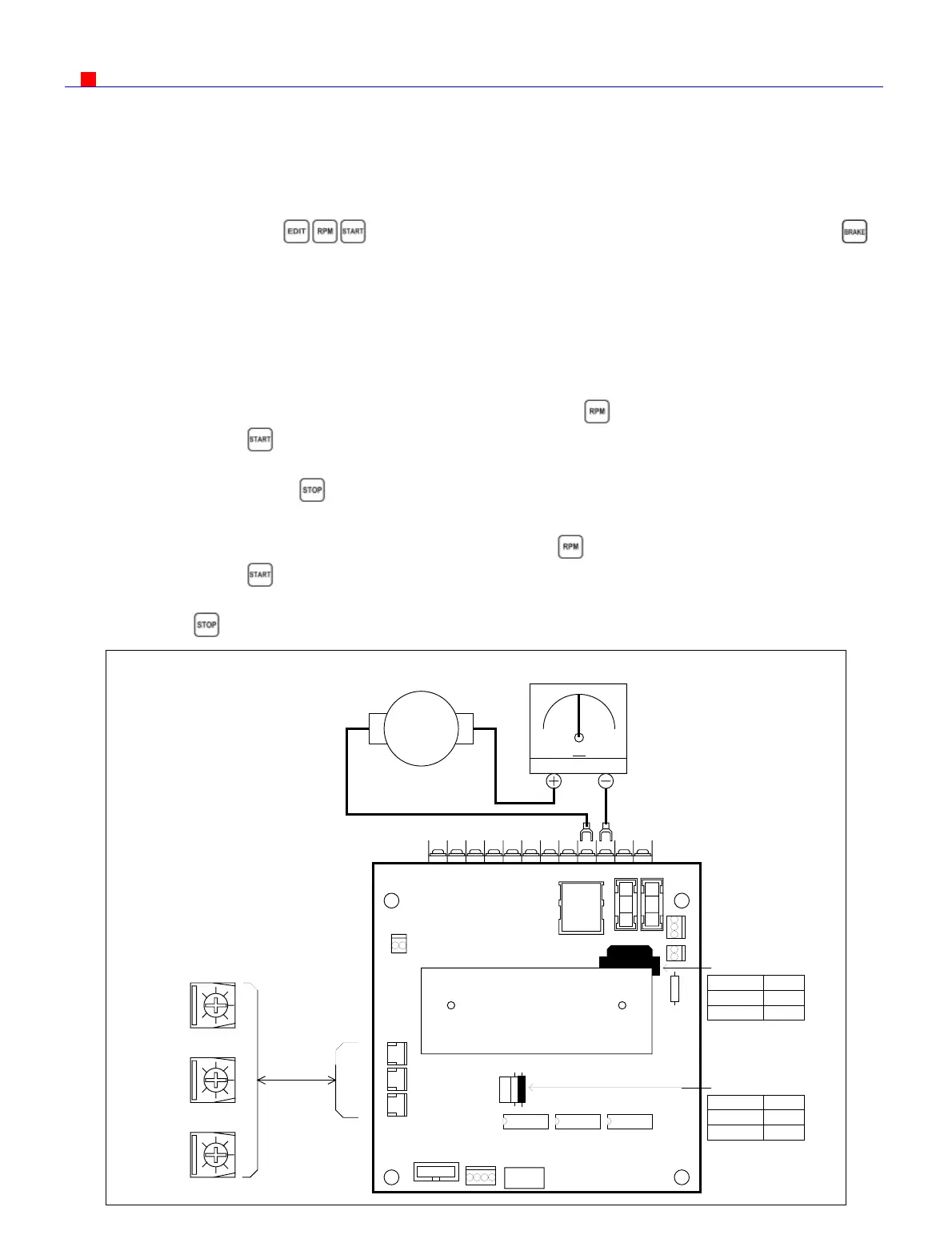

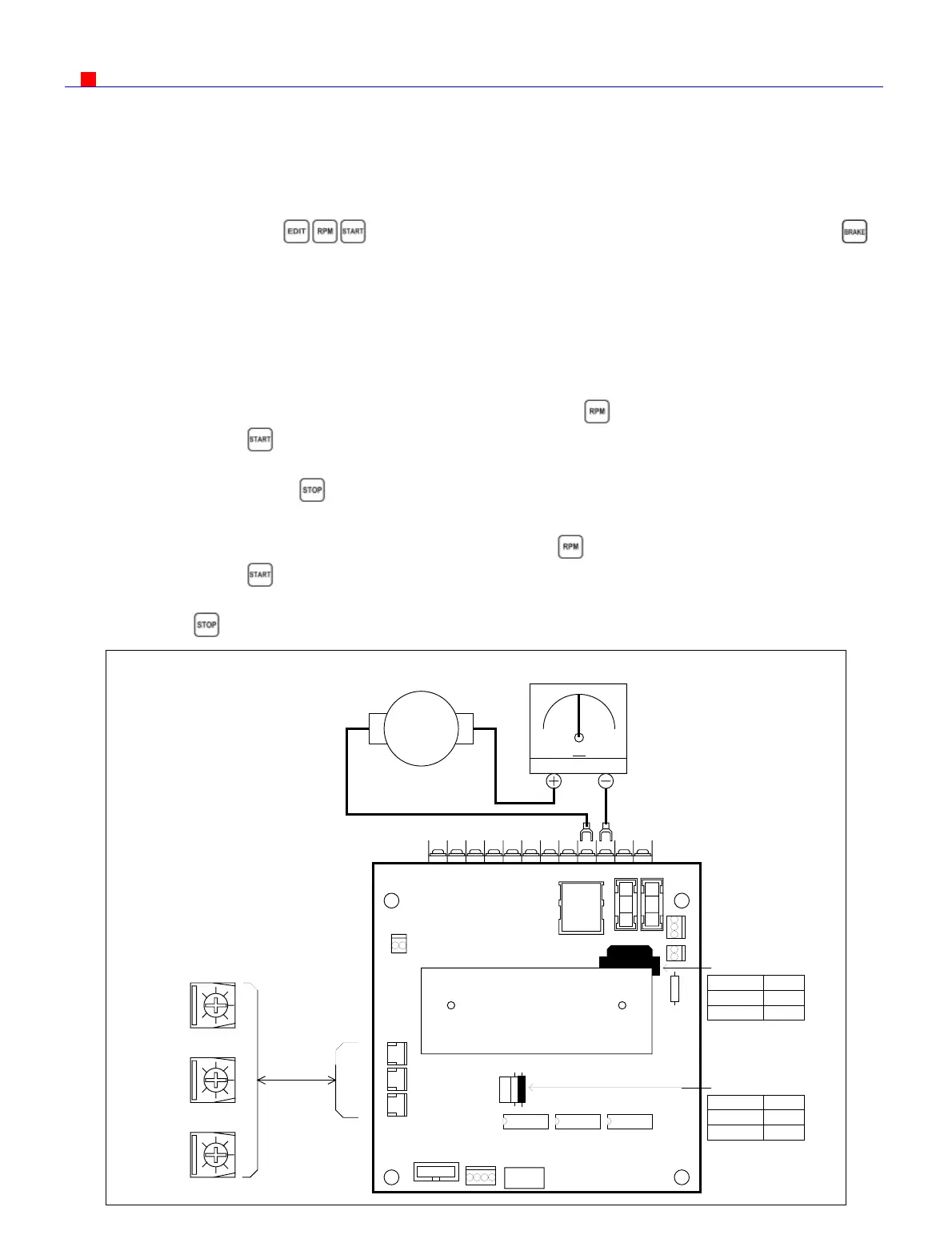

1. Connect a DC Amperes meter between terminal and DC motor as below.

2. In ready mode press to make the DC motor starting rotate and then press to

holding the winding spindle.

3. Rotate CL to set limited current, show on Amperes meter.

( 2A for 180v DC motor

、

4A for 90v DC motor).

(The CL have been set by factory before delivery. Only adjust it when change DC motor

and replace 210A-DVR driver board.)

IR

:

Torque compensation.

1. Set the winding parameter H.S., L.S. in 20, then press to change the DISPLAY shows

RPM. Then press key to start winding.

2. Rotate IR potentiometer to make it in same speed during the winding spindle shaft in full-load

and unload. Then press key to stop winding.

MAX

:

Maximum winding speed.

1. Set the winding parameter H.S., L.S. in 99, and press key to change the DISPLAY shows

RPM. Then press key to start winding.

2. Rotate MAX potentiometer to make the winding speed (RPM) as you want.

Then press key to stop winding.

SCL-DPDT

COIL-24V-DC

RY1

CL I R MAX

FUSE2

T1

210A-DVRID:XXXXXX

TAILY

AUTO

0

1010

A

AMPERE METER

10A

M

DC MOTOR

LHLHLH

CL IR MAX

FUSE1

CN1CN2

CN3

CN4

CN5

R32

R38

R33

C33

T1

R33

POWER

AC 100~120V

AC 220~240V

T1

TF808C1

TF808C2

POWER

AC 100~120V

AC 220~240V

R33

82K

47K

Loading...

Loading...