T2200P Weighing Indicator User’s Guide

- 16 -

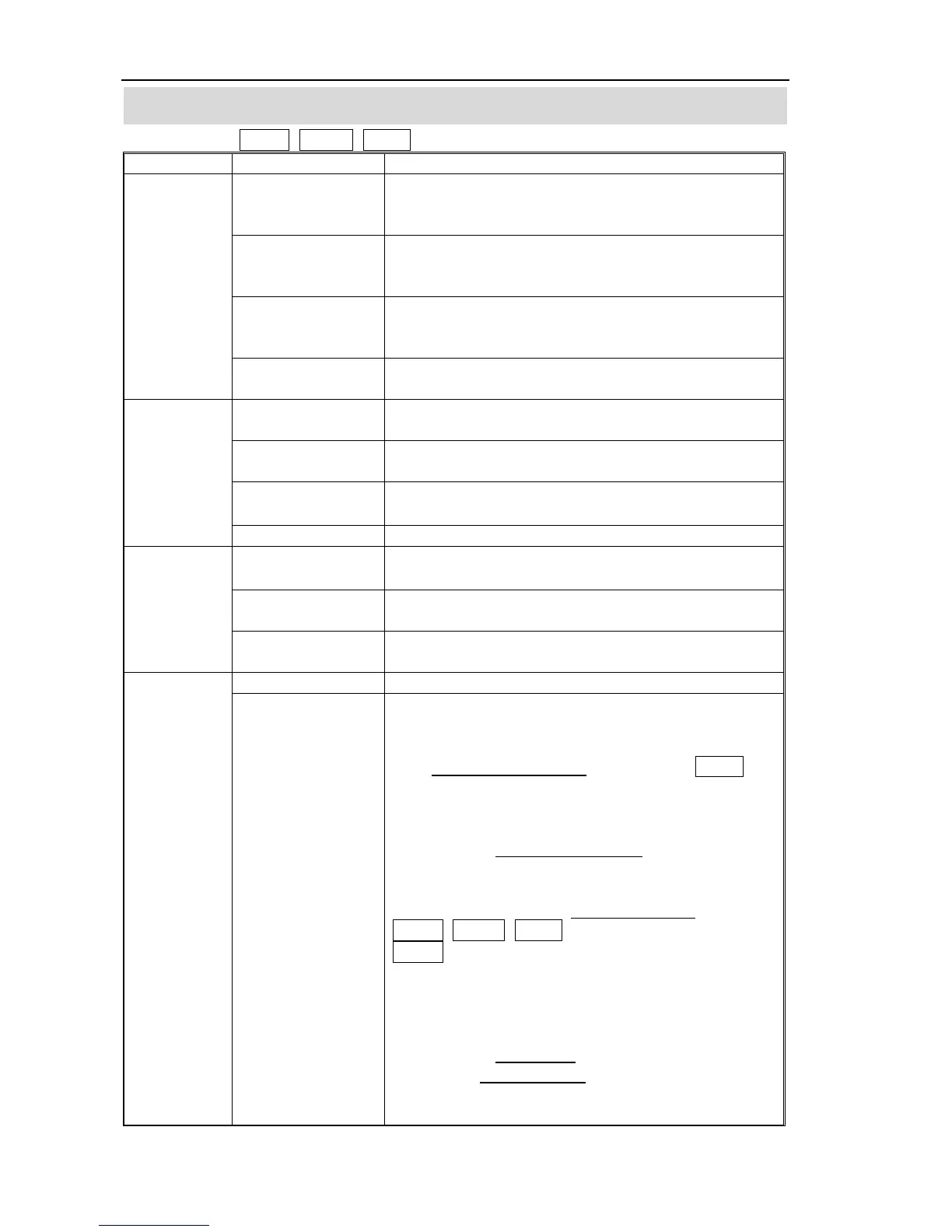

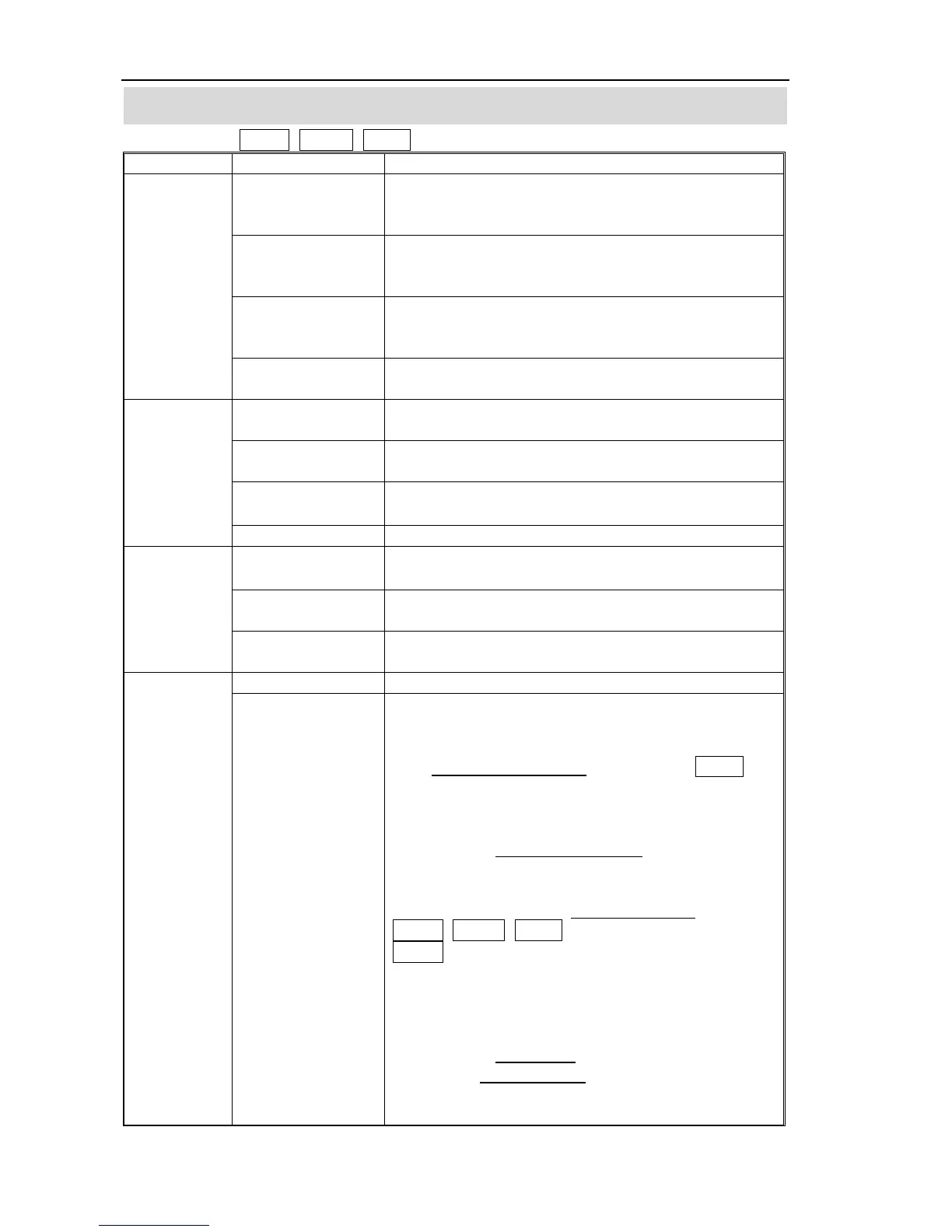

SECTION 11 TECHNICAL PARAMETERS

You can press SMPL, PRINT, TARE key to enter setting mode at PROG mode

FUNCTION SUB-FUNCTION DESCRIPTION

AZN 0

This option is used to select the auto zero

maintain

Options : 0.5d, 1d, 2d, 4d

0-AUTO

This option is used to select the auto zero range

when turn the indicator.

Options : 0%, 2%, 5%, 10%, 20%

0-RANGE

This option is used to select the manual zero

range when press the ZERO key.

Options: 2%, 4%, 10%, 20%, 50%, 100%

P1 REF

SPEED

Set the ADC speed

7.5/15/30/60 times/second

DECI

This option is used to select the decimal

Options : 0, 0.0, 0.00, 0.000

INC

This option is used to select the division

Options : 1, 2, 5, 10, 20, 50

CAP

This display will show xxxxxx for setting the

capacity.

P2 CAL

CAL

Calibrate, see detail in SECTION 10

TRI

This display will show xxxxxx for trimming the

load cells .

COUNT

This display will show xxxxxx for indicating the

internal counts.

P3 PRO

RESET

This display will show SURE for recovering the

factory default setting.

MODE 0

This is mode of the natural scale

P4 CHK

MODE 1

This is parameter of the animal scale

If you set MODE 1, then will display some

parameter to set the animal scale

First set the shake range, you can use TARE key

to select 0/5/10/15/20/25/30/35/40/45/50, (0

means disable) reading data shake between the

range you set, the reading will be lock.

Then set the reading lock option

, A 1(lock the min

data), A2(lock the average data), A3(lock the

max data)

Then set the new data increment value

, use

SMPL, SHIFT, TARE key to enter the data, use

ZERO key to sure. After you set these data,

when reading have been locked, if you add

goods again to the platform or release goods

more than this weight, the reading will be update

and lock again.

Then set the delay time: 10/20/30/40.

At last, set lock condition (3/4/5/6/7/8), 3 means if

find continuous 3 times data between the range,

data will be locked.

Loading...

Loading...