5-55

MAINTENANCE

10. Remove the relay and fuse panel (9).

11.Loosentheboltsandremovetheange

(7).

12. Remove the suction strainer (8) and

clean it.

13. Clean the inside of the hydraulic tank.

14. Remove the connector (C) and install the

cap (B).

15. Install the suction strainer (8) on the tank

and then install the flange (7).

16. Install the new return filter (5) and the

flange (4) on the tank.

17. Add hydraulic oil from the hole of plug (3)

up to the level between the upper limit

(H)andthelowerlimit(L)inthesight

gauge (1).

18. Tighten the plug (3).

19. Install the relay and fuse panel (9).

20. Bleed air from the hydraulic oil circuit

following “Bleeding air” below.

21. Set the machine to the hydraulic oil level

inspection posture and inspect the oil

level after the oil cools.

Refer to “Inspect the hydraulic oil tank

level and replenishing” on page 5-20.

Bleeding air

IMPORTANT: After replacing the hydraulic

oil, bleed air from the hydraulic circuits

and hydraulic devices. Failure to do so

may damage the hydraulic devices.

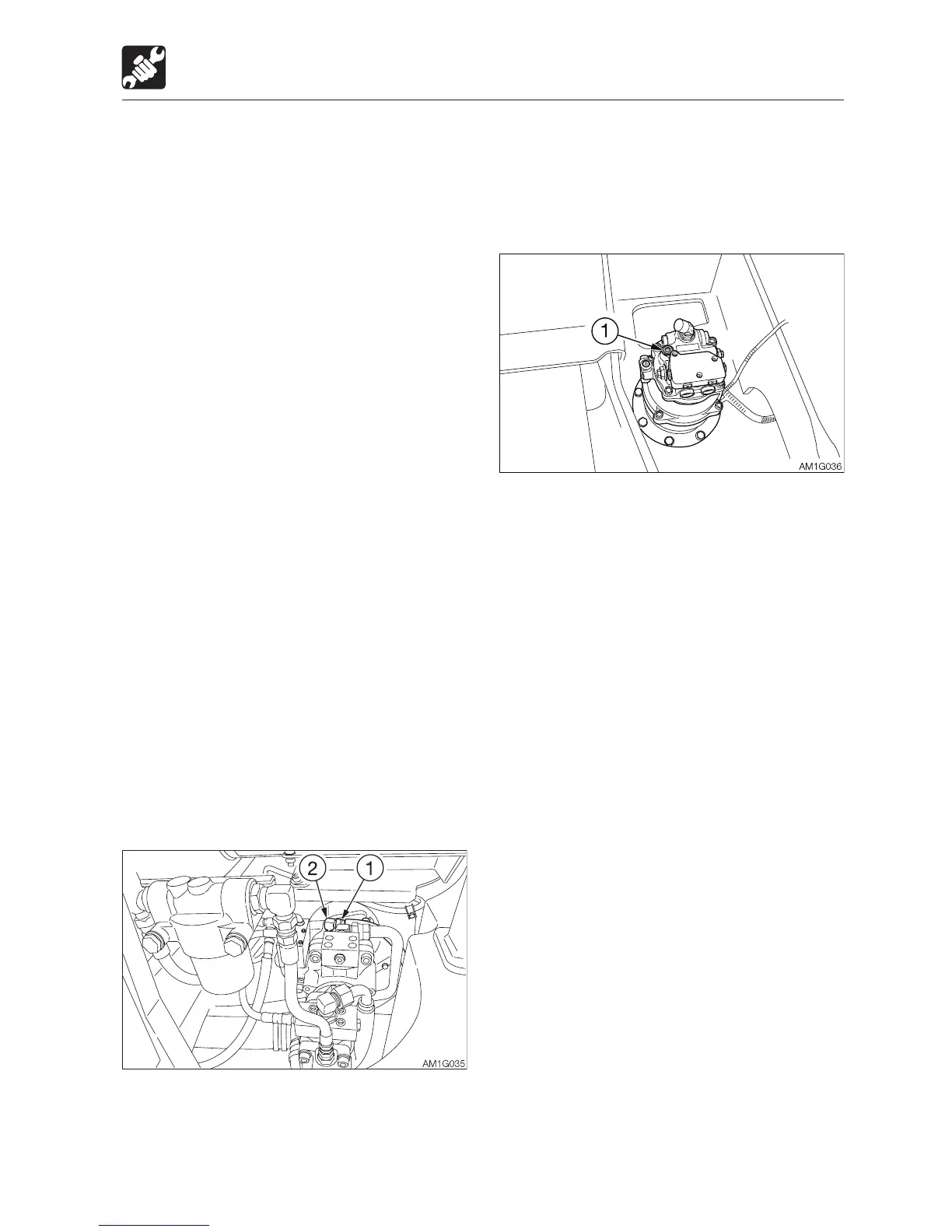

•Hydraulicpump

EVERY 4000 HOURS

1. Open the engine hood.

2.Loosenthedrainhose(1)ofthehydraulic

pump.

3.

Tighten the drain hose (1) once there are

no more air bubbles coming from the

elbow(2)joint.

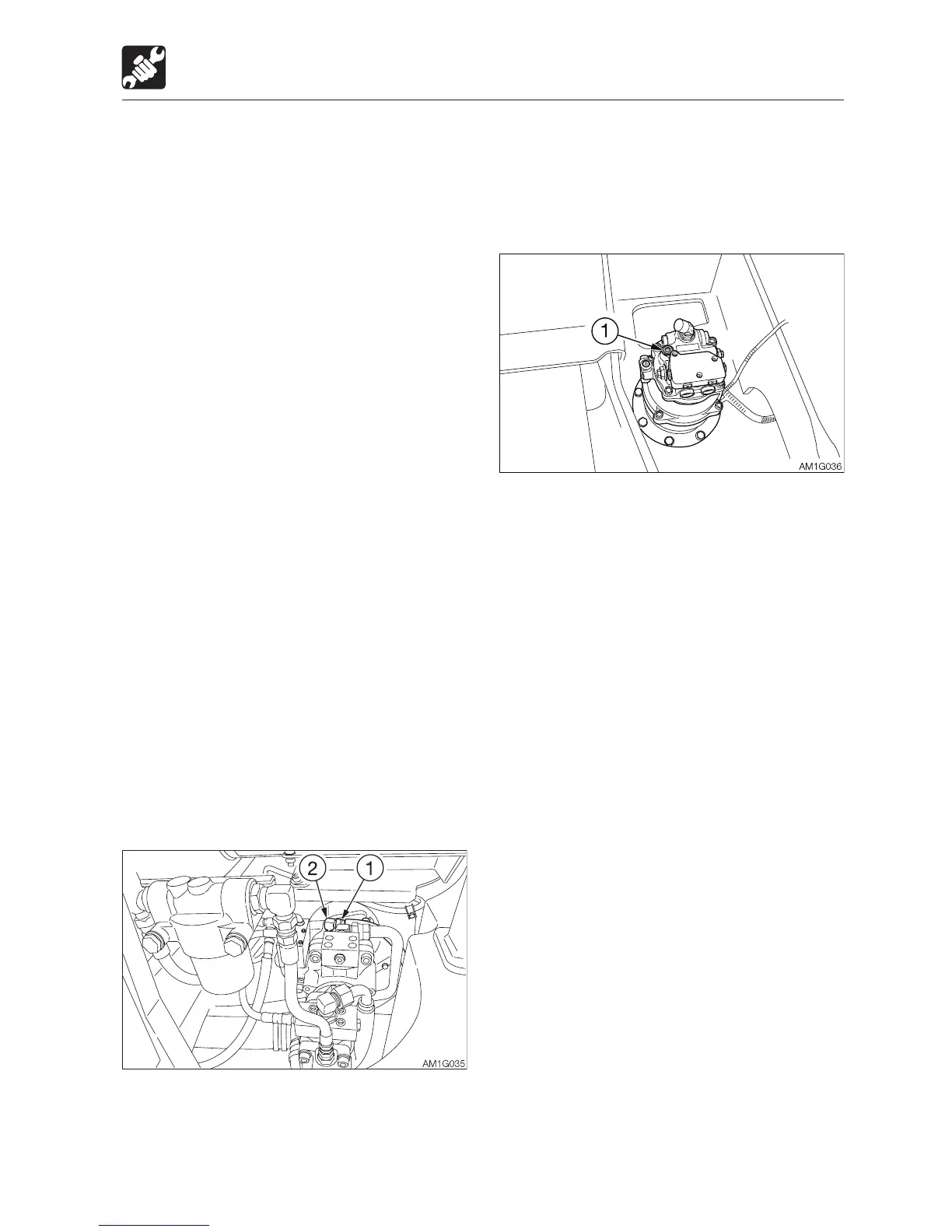

•Slewmotor

1.Loosentheair-bleedingplug(1).

2. Tighten the plug (1) once the hydraulic oil

overflows from the air-bleeding plug hole

(1).

•Cylinders

1. Start the engine, let it run at a low-idling

speed for 10 minutes.

2. Maintain the engine at low idle, and then

slowly extend and retract each cylinder 4

or 5 times, without letting them reach the

stroke end.

3. While running the engine at high speed,

slowly extend and retract each cylinder 4

or 5 times, without letting them reach the

stroke end.

4. Return the engine speed to low idle, and

then slowly extend and retract each

cylinder 4 or 5 times to the stroke end.

Loading...

Loading...